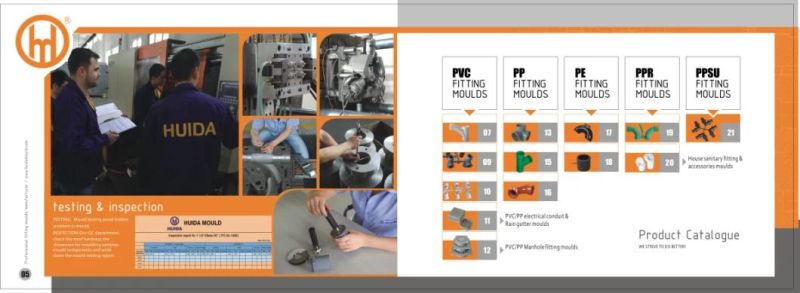

Professional Plastic Mold Manufacturer Wholesale Low Price Innovative

Taizhou Huangyan Huida Plastic Machinery Co., Ltd.- Plastic Material:PVC

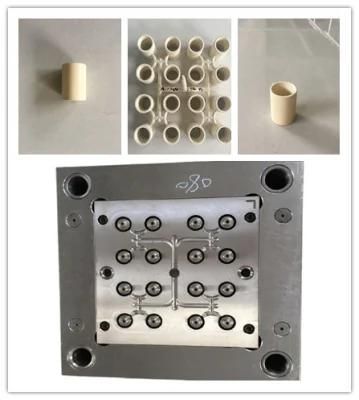

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances

- Design Software:UG

Base Info

- Transport Package:Wooden

- Export Percentage:95%

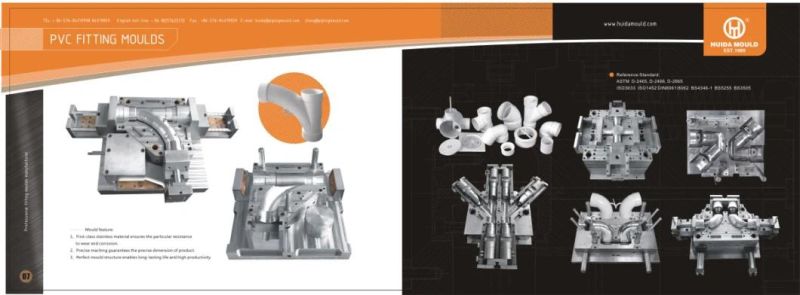

- Fitting Standard:En,DIN,BS,ASTM

- Gate:Direct,Point,Submarine,Rectangle,Side,Tunnel

- Surface Treatment:Polish. Etched. Texture

- Mould Base:European Standard

- Mould Material:Mould Material

- OEM:Our Factory Can Accept OEM

- Mould Life:300000-1000000shots

- Cooling System:in Core Baffle and in Cavity Plate Chain Drilling

- Customized:Customized

- Certification:ISO

- Installation:Mobile

- Model NO.:PVC

- Specification:1,2" to 12"

- Trademark:HUIDA MOULD

- Origin:Zhejiang, China

- HS Code:3323963208

- Production Capacity:2000sets,Year

Description

Basic Info.

Model NO. PVC Installation Mobile Certification ISO Customized Customized Cooling System in Core Baffle and in Cavity Plate Chain Drilling Mould Life 300000-1000000shots OEM Our Factory Can Accept OEM Mould Material Mould Material Mould Base European Standard Surface Treatment Polish. Etched. Texture Gate Direct/Point/Submarine/Rectangle/Side/Tunnel Fitting Standard En/DIN/BS/ASTM Export Percentage 95% Transport Package Wooden Specification 1/2" to 12" Trademark HUIDA MOULD Origin Zhejiang, China HS Code 3323963208 Production Capacity 2000sets/YearProduct Description

Q1: What kind of molds do you make? Plastic injection mold, Compression mold or something else?

A1: We are mainly making plastic mold injection and rubber compression mold.Sometimes we also make die casting molds according to our customer's requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems we can accept following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q5: Can you provide the steel certificate and heat-treatment certificate?

A5: Yes, We can provide steel certificate or hardness certificate to prove.

Q6: Can you make the texture / text / heat-treatment /nitriding for the inejction mold plastic?

A6: Yes, As plastic mold fatory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold's size and complexity.Normally, the lead time is 25-45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or required by client.

Q9: How do you pack the china plastic moulds?plastic injection mold packaging?

A9: We pack the plastic moulds with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement.

Q10:What is your terms of packing?

A10.Generally, we pack our goods in wooden case or as per required. Mould surface will be painted. Use anti-rust oil inside the mold, plastic film outside, and use standard export wooden case for seaworthy shipping. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.Huida plastic mould factory is situated in Huangyan, Zhejiang province. Being specialized in design and manufacture kind of plastic pipe fiting moulds since it's established in 1989. After long time innovation and hard work long time, Huida have enjoyed great reputaion in global Plastic Pipe&Fitting mould as a corporate member of China Mould Industry Association and China Plastic Pipe &Fitting Council, now Huida is the largest and most professional fitting moulds manufacture in China.