Rearview Mirror Mold D

Green Vitality Industry Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS+CF

- Mould Cavity:Multi Cavity

- Surface Finish Process:Painting

- Shaping Mode:Injection Mould

- Application:Car, Commodity

Base Info

- Specification:Customized

- Transport Package:Plywood Case

- Spare Parts Standard:Dme, Hasco, Daido, Misumi, Customized

- Standard:HASCO

- Customized:Customized

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:GV-Mold

- Trademark:GV

- Origin:China

- HS Code:84807100

- Production Capacity:500sets Per Year

Description

Basic Info.

Model NO. GV-Mold Runner Hot Runner Design Software UG Installation Fixed Certification TS16949, ISO Standard HASCO Customized Customized Spare Parts Standard Dme/ Hasco/ Daido/ Misumi/ Customized Transport Package Plywood Case Specification Customized Trademark GV Origin China HS Code 84807100 Production Capacity 500sets Per YearProduct Description

Customized Plastic Rearview Mirror Injection Mould D

Basic Information for Plastic Part & Mould:

| Part Name | Plastic Parts | Mold Type | Plastic Injection Mold |

| Part Material | PC, ABS, PP, PA, PA+GF, PBT, BMC, PMMA, PC+ABS, PP+TD20%, POM, PE, PVC etc. | Mould Steel Material | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh etc. |

| Part Size (mm) | as per Drawing, Sample, or Design | Mould Dimension (mm) | as designed, 1200*1000mm max. |

| Part Weight (g) | as per Drawing, Sample, or Design | Mould Weight (kg) | as designed, 10 tons max. |

| Injection Machine (Ton) | TBA when quote | Mould Cavity No. | Single or Multiple |

| Injection Cycle (s) | TBA when quote | Runner System | Hot or Cold runner, pin-point gate, etc. |

| Tolerance | as required | Mold Components Standards | DME, LKM, HASCO or equivalent |

| Secondary Operations | Silk-screen Printing, Electroplating, Painting, Coating, Assembly, Package etc. | Surface Treatment | Mirror Polish, Matt, Texture VDI etc. |

| Application | Auto Parts | Mould Life (Shots) | 100,000 ~ 1,000,000 shots as required |

| Special Requirements | Food Grade, BPA free, UV resistant, Fire Resistant, Waterproof etc. if required | Special Requirements | Moldflow Analysis if request, or as customers' request |

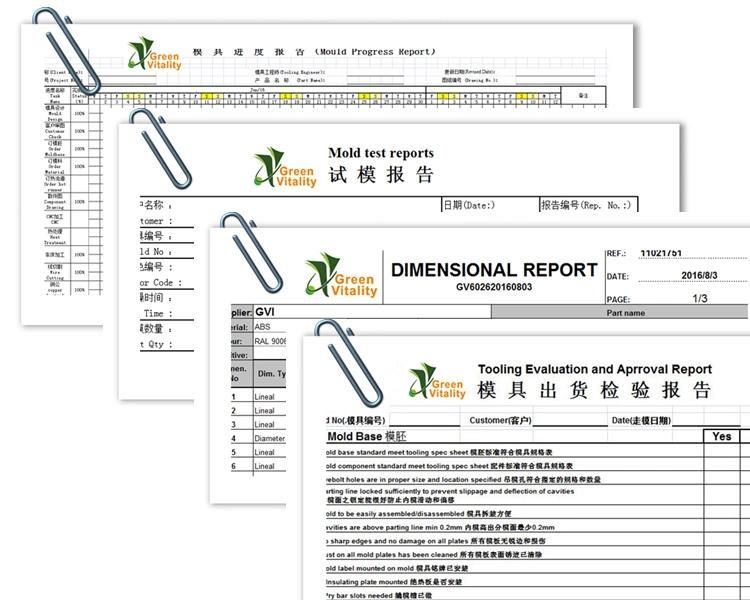

* ISO 9001:2015 approved.

* Supply molds and products to over 30 countries.

* Have professional sales team with good English capabilities and communication skills.

* Offer OEM/ODM service.

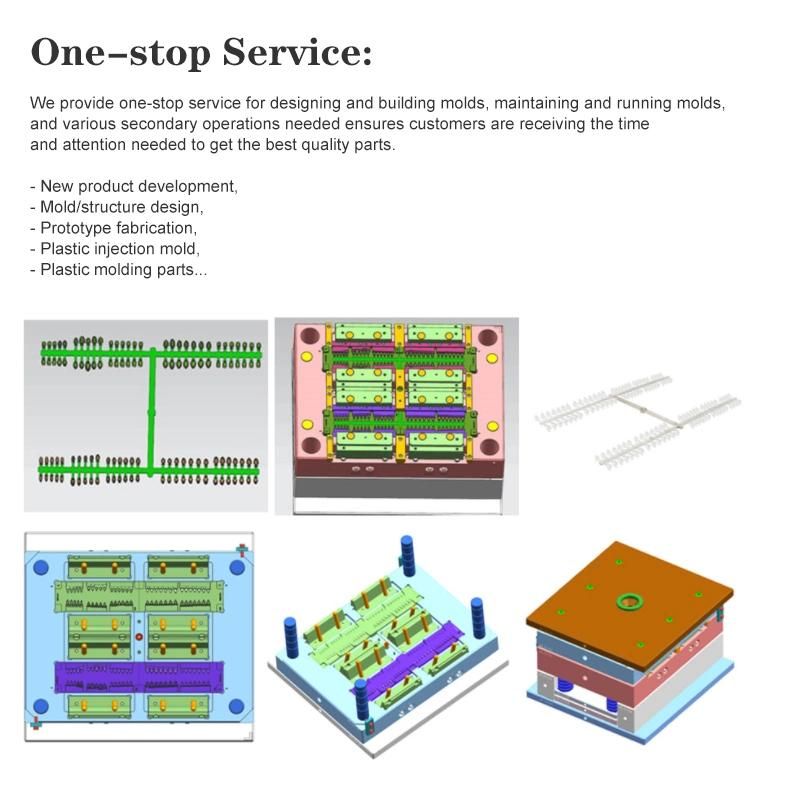

* Provide value-added and one-stop service from plastic injection mold design to delivery.

* Ensure high quality with professional design team, project engineer, QC and R&D teams.

* Offer in-house mold design and building capabilities.

* Protect your idea and design through confidentiality agreement.

* Provide secondary operation service of dustless auto painting, electroplating, silkscreen with our partner factories.

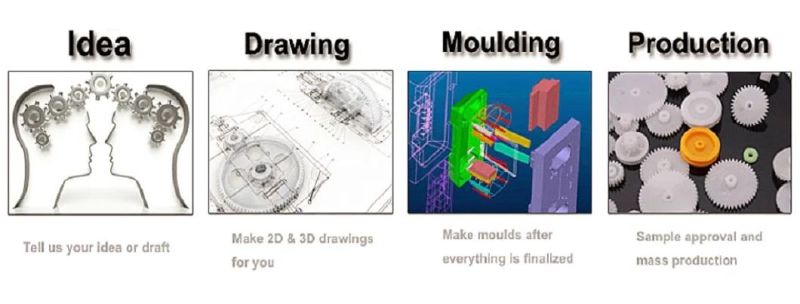

* Make prototype 3 - 7 days.

* No MOQ limited * Prompt delivery.

* Reach airport or sea port within one hour, near Hong Kong.

Why choose us?

* ISO 9001:2015 approved.

* Supply molds and products to over 30 countries.

* Have professional sales team with good English capabilities and communication skills.

* Offer OEM/ODM service.

* Provide value-added and one-stop service from plastic injection mold design to delivery.

* Ensure high quality with professional design team, project engineer, QC and R&D teams.

* Offer in-house mold design and building capabilities.

* Protect your idea and design through confidentiality agreement.

* Provide secondary operation service of dustless auto painting, electroplating, silkscreen with our partner factories.

* Make prototype 3 - 7 days.

* No MOQ limited * Prompt delivery.

* Reach airport or sea port within one hour, near Hong Kong.

2) Part material: ABS, PP, POM, PC, PS etc.

3) Part Annually forecast or minimum order quantity 4) Specifical requirement: such as food-grade, medical grade, UV resistant.

5) Plastic components Application 12. What information needs for quotation & design of Molds? 1) Mold Runner type: cold or hot

2) Mould steel material: P20, 718, 2738, H13, S136 an so on. 3) Mold Cavity 4) Mold Life 5) Mold Standard: LKM, DME or HASCO or equivelent 6) Surface treatment requirements 7) The tonnages of Injection Machine

8) Plastic components function

9) Other key points

"Wonderful Design + Professional Mold maker = Perfect Product" You will enjoy our good service and cost-effective solutions from design to delivery. Welcome to contact us!