Plastic Injection Mould for Airport Trays

Green Vitality Industry Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Heat Treatment

- Application:Household Appliances, Furniture, Commodity, Electronic, Home Use

Base Info

- Specification:As per request

- Transport Package:Ply Wood Box

- Mold Life:300, 000 to 1, 000, 000 Shots

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:GV-mold

- Trademark:GVI

- Origin:China

- HS Code:8480710090

- Production Capacity:500 Sets ,Year

Description

Customized Service & Application

Different sizes, different shapes based on your requirement.

About Us:

GV-Mold is a professional injection mold manufacturer.

Our severice main on custom indurstial parts, electronic products, kitchen ware, medical instruments, auto parts, and household appliances.

| Automotive | Auto interior plastic case, Auto inner parts, Bumper, Door plate, Lamp shell, Instrument panel, auto connectors , Electrical switch; Car gear, Complete sets of motorcycle parts; |

| Electronic | Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards, USB Connector, USB housing, Mobile phone plastic part, remote control, key-press; |

| Mechanical | Motor support plastic part, Pump plastic part, mower plastic parts; |

| Household | Fashion cup, Juice cup, Some small plastic parts; |

| Home appliance | TV front cover, TV rear cover, Display cover, Air-conditioner or Refrigerators plastic parts, Washing machine part; |

| Medical | Hollow fiber dialyzer, Deaf-aid parts, Medical instrument body plastic parts, Blood-pressure meter parts, Blood-pressure meter, Stapler. |

Our advantage and service:

1. We are a mold manufacturer,so we quote the first-hand quotation, no middleman.

2.We have the self-management import and export license.

3. We have been in the mold industry for 25 years, all of our sales staff have more than 5 years of mold industry experience.

4. All of our molds quality based on Europe standard and American standard.

5. Prompt afer-service. We provide lifetime after-sale technical support.

6.One-stop service and No MOQ limited.

Your OEM and ODM model are welcomed.

* Customize drawings or design or idea can be realized.

* Design the drawings according to your drawing, sketch or samples.

* Small prouction orders are also acceptable.

* High quality and short lead time, professinal and cost-saving mold solution supplier.

We manufacture, assemble, pack, store and distribute

Once your semi-finished products have been manufactured, we are able to assemble your items, and also complete the production cycle through to final packaging, ready for distribution to anywhere in theworld.

We have the capability to add additional components which we either produce or source from worldwide partners, assemble and package your products to complete the manufacture of your items.

This is an one stop service which is hard to be beat.

We hope you to be able to concentrate on what you are good at, and leave the rest to us!

Highlights

General assembly, by individuals and on production lines by teams.

Hotplate welding.

Heat stacking of inserts.

Ultrasonic welding assembly of plastic components.

Manual assembly of components to build up subassemblies or finished assemblies,

Packing.

"Wonderful Design + Professional Mold maker = Perfect Product"

You will enjoy our good service and cost-effective solutions from design to delivery.

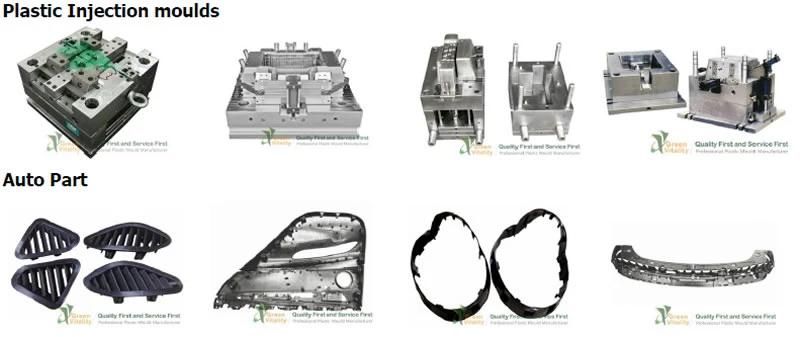

Sample show:

Contat and Cooperation:

If you have a project you would like us to evaluate, please send the technical drawings and specifications, we'd be happy to assist you.

Address: Building 6, North Yongfa Industrial Park, No.16, Daxing 1st Road, Shajing Town, Bao'an District, Shenzhen, CN (518104)