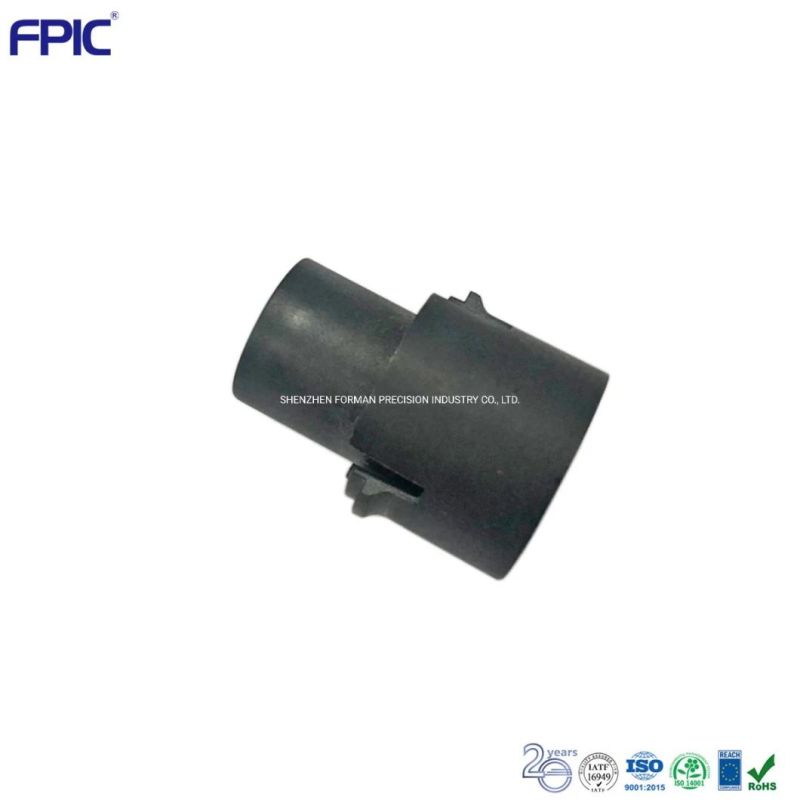

Custom Nylon Injection Molding Components RoHS Compliant PA9t Precision Plastic Small ...

SHENZHEN FORMAN PRECISION INDUSTRY CO., LTD.- Process Combination Type:Progressive Die

- Plastic Material:PA66+GF

- Mould Cavity:Multi Cavity

- Surface Finish Process:N,a

- Shaping Mode:Injection Mould

- Application:Car, Commodity, Electronic, Hardware, Precision Industry

Base Info

- Our Feature:Full-Auto Production Line and Own Lab. at Home

- R&D Capacity:More Than 10 R&D Engineers

- Operation:Auto Injection

- Delivery Time:Within 10 Working Days

- Mould Manufacturer:at Home

- Management System:ERP

- Certificate:ISO9001, ISO14001, IATF16949

- Drawing:3D Drawing with 2D Files

- Testing:Humidity and High-Temp Test

- Quality Assurance:RoHS and Reach Compliant

- MOQ:1, 000 PCS Per Lot

- Material:Plastic Injection

- Customized:Customized

- Design:Custom Design

- Certification:TS16949, ISO, RoHS,Reach,etc.

- Installation:N,a

- Design Software:UG

- Runner:Hot Runner

- Fabricate Capacity:Plastic Injection, Metal Stamping and Mould Make

- Location:Shenzhen, China

- Transport Package:PE Bag,Tray+Carton

- Specification:OEM,ODM

- Trademark:OEM

- Origin:Shenzhen, China.

- Production Capacity:10.000 to 50, 000PCS,Day

Description

Plastic Injection molding Samples

Who is Forman

Shenzhen Forman Precision Industry Co., Ltd has become the global leading supplier in electronic components since found in 1999, as our innovative design, strong production competence and strict quality management.

Until 2018, Forman total investment has been over USD10 Million, completely achieved scientific automatic manufacture in plastic injection, metal stamping, and assembly then has past ISO9001, ISO14001 and IATF16949 certification. Meanwhile, we are constantly introducing foreign advanced equipment, technology, and company management experience, insisting on developing and attracting multi-skill technology talented people to establish a high efficiency, high-quality production team.

Forman is committed to optimize factory strength, improve quality control system and enrich R&D capacity to face greater challenges and meet different requirements. By now, you can see Forman production in consumer electric, automotive electronics, medical industry and so on.

Certifications & Awards

Forman has established the longterm and friendly business relationship with all our customers for more than 10 years.

We offer one-stop manufacture services from mold to final assembly and packaging, Forman insists on full automatic fabrication to offer high-efficiency and stable quality. There are more than 30 sets of injection machines, 35 sets punching and 20 assembly lines in our factory to satisfy in our factory and monthly output capacity at least 72,000,000 pcs. Each order will be finished within 5~7 working days, we only offer high-quality products.

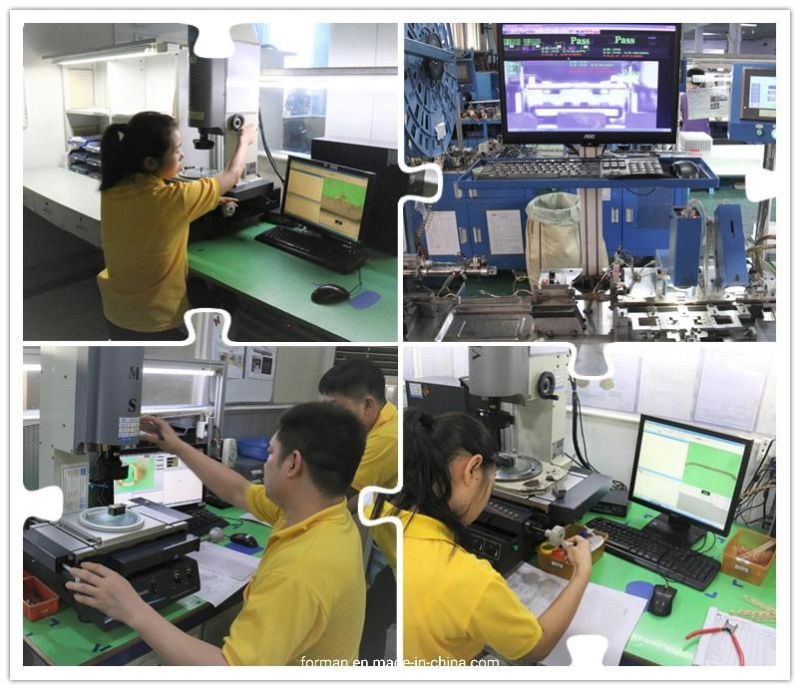

Workshop Display

Forman offers 100% quality assurance to all our customers and has introduced a series of advanced testing equipment aboard to satisfy differences requests, then we will have a quality training class per month for all our QC employees to improve their skills.

Quality Assurance

More and more detail information will be offered and answered, kindly feel free to contact us when you have any question. Kindly feel free to share your technical drawing and specification with us for professional services, our R&D engineers are all with more than 10 years experience in related industries.