Stamping Tool Press Tool Progressive Tool

Qingdao Higrade Moulds & Products Co., Ltd.- Technics:Forming Die

- Processing Method:Punching and Shearing Mould

- Material:Hard Alloy and Steel Bonded Carbide

- Application:Household Appliances, Electronic, Car

- Warranty:1 Year

- Process Combination:Progressive Die

Base Info

- Place of Origin:Qingdao,China

- Progressive Pressing Die Life:50000~500000shots

- Progressive Die Design:2D&3D

- Progressive Pres:Cr12MOV, SKD61, SKD11

- After-sales Service:Yes

- Parts Detection Method:Geometric Detection

- Milling Speed:High Speed

- Mold Cavity Technology:EDM Milling

- Driving Motor Type:Permanent Magnet

- Manufacturing Technology:Computer Technology

- Model NO.:HRD-Z347

- Transport Package:Wooden Case

- Specification:ISO9001: 2015

- Trademark:Higrade

- Origin:China Qingdao

- HS Code:8207300090

- Production Capacity:500 Sets,Year

Description

Basic Info.

Model NO. HRD-Z347 Manufacturing Technology Computer Technology Driving Motor Type Permanent Magnet Mold Cavity Technology EDM Milling Milling Speed High Speed Parts Detection Method Geometric Detection After-sales Service Yes Progressive Pres Cr12MOV, SKD61, SKD11 Progressive Die Design 2D&3D Progressive Pressing Die Life 50000~500000shots Place of Origin Qingdao,China Transport Package Wooden Case Specification ISO9001: 2015 Trademark Higrade Origin China Qingdao HS Code 8207300090 Production Capacity 500 Sets/YearProduct Description

Product name: Progressive diePlace of origin: Qingdao, China

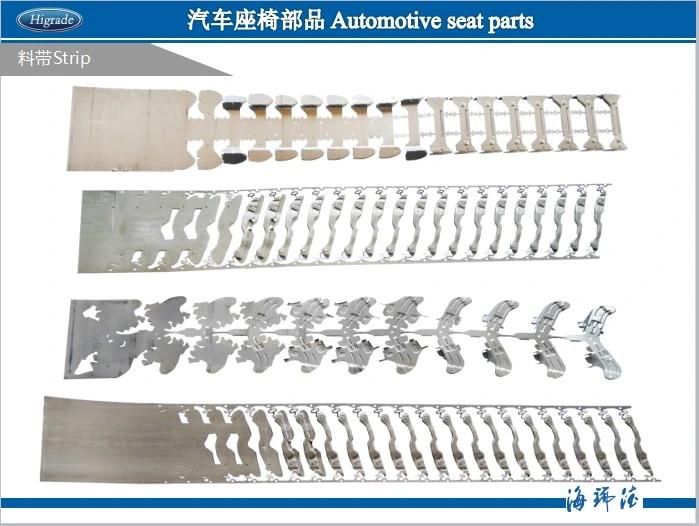

PROGRESSIVE PARTS:

1) We specialize in Progressive die, progressive tooling, progressive matrix, progressive mould, progressive stamping die. We had export some metal progressive moulds to Argentina, Germany, Japan, Italy, Iran, USA, etc.

2) The progressive dies are related to gas cooker, automobile industry, washing machine stamping tooling, commodity, home appliance etc.

3) Staming die material: CR12MOV, SKD11, 45#

Cavity: Single

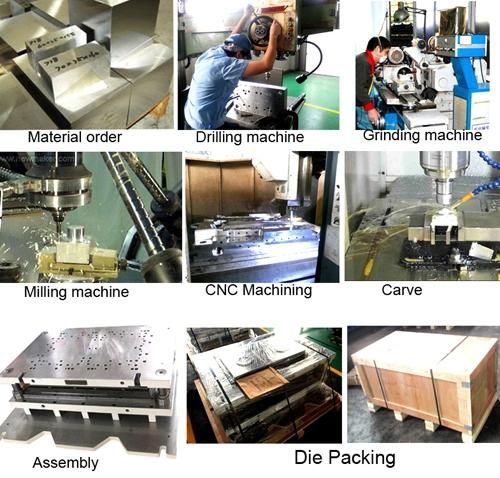

PRODUCTION PROCESS:

Drawing format: . Igs, . Step, . X_t, . Pdf, . Dwg, . Dxf

Mould life: 500000 shots

First trial time: 35 days after mould structure drawing confirmed.

4) ISO9001: 2008 certified by SGS.

| Step | Item | Description |

| 1 | Quotation | We offer you the stamping die and part quotation according to your details (drawing or sample,material,quantity,weight). |

| 2 | Order | If our quotation is competitive,you will place the order. |

| 3 | Drawing design | We design the mould structure drawing according to your product drawing or sample,then send to you for confirmation. |

| 4 | Mould making | After your confirmation of our drawing,we begin to make the moulds,during manufacturing program,we send you mould building progress with pictures every week,for you to know our process. |

| 5 | First trial | We will make the stamping die first trial on time, then send you video, picture and samples for you to confirm. |

| 6 | Quality confirm | You will confirm our stamping die quality according to sample. If you need to adjust the product structure,we can help you to change it further. |

| 7 | Delivery | Ship the stamping die after it is completely OK,packed by wooden case. |