Plastic Water Mug Injection Mould

TAIZHOU U-KNOW MOULD CO., LTD.- Process Combination Type:Single-Process Mode

- Plastic Material:PC

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Furniture, Commodity, Home Use

Base Info

- Transport Package:Wooden Case

- Product Material:PP,PC,ABS

- Steel:P20,718h

- Customized:Customized

- Standard:HASCO

- Installation:Fixed

- Design Software:UG

- Runner:Hot,Cold Runner

- Model NO.:UKB016

- Specification:10L,20L,50L

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:300 Sets,Year

Description

Basic Info.

Model NO. UKB016 Runner Hot/Cold Runner Design Software UG Installation Fixed Standard HASCO Customized Customized Steel P20,718h Product Material PP,PC,ABS Transport Package Wooden Case Specification 10L/20L/50L Trademark UK Origin China HS Code 8480719090 Production Capacity 300 Sets/YearProduct Description

Product DescrptionWe have a wealth of experience in Water Jug mould,Mop Bucket Mould,covering round, rectangular, square and oval from 50ml to 35L.We make bucket mould with one cavity,handle mould with 2 or 4 cavity. We can also provide kinds of color ,style,shape as your requirement.To avoid any flash on the product,we employ advanced surface treatment,such as polishing, sand blasting, heat treatment.

Our Advantages

1. Professional technology support. We have over 30 senior mold engineers for your plastic mould inquiry.

2. High quality. The plastic mould is made with good mold material to guarantee the long life, such as SKD61, NAK80,2344,S136,718H,738H,2312 and so on.

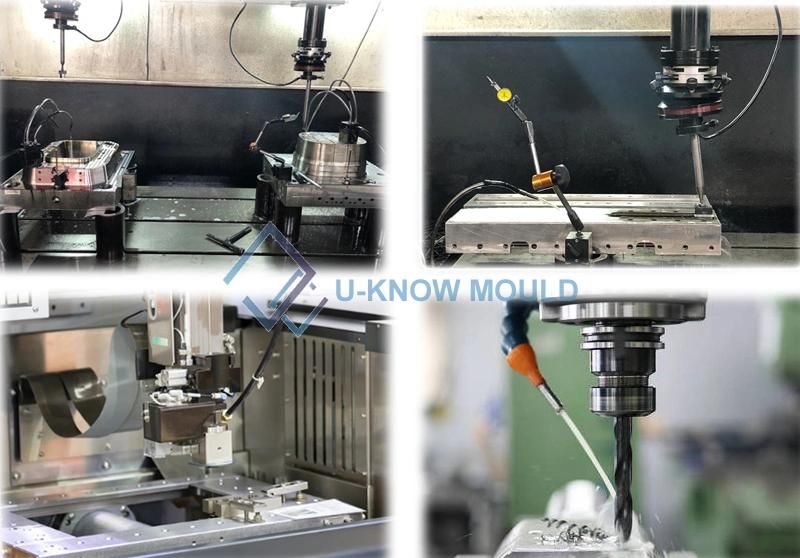

3. Precision machining. We have our own mold room with CNC, WEDM-LS and other advanced equipment, the precision machining will be offered for your high quality requirements.

4. Rich experience. We have made plastic mould for automotive and home appliance from 2003, and our products include lots kinds of household appliance and automotive products.

5. Standard parts with PUNCH, MISUMI, Dayton. You can keep maintenance easily in your own production.

About Us

Packaging & Shipping

Anti-rust oil is painted first, then plastic film, and finally wooden case.

Sent together with the mould:

a) Mould manual instruction

b) Engineering drawing in flash disk

c) One more set of mould spare parts: heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

Contact Us