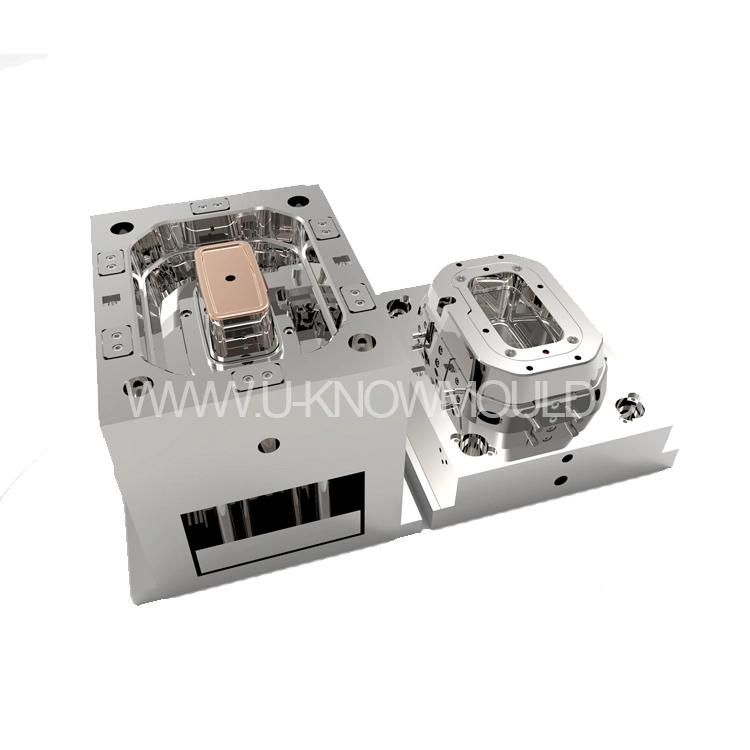

Plastic Dining Box Mold/Plastic Linch Container Mould

TAIZHOU U-KNOW MOULD CO., LTD.- Process Combination Type:Single-Process Mode

- Plastic Material:PP, PC, PS, PE, PU, PVC, ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Commodity, Home Use

Base Info

- Specification:45#, P20, H13, 718, 2738, NAK80, S136etc.

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:Ug,CAD,PRO-E

- Runner:Hot,Cold Runner

- Model NO.:UKB005

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:300 Sets,Year

Description

Basic Info.

Model NO. UKB005 Runner Hot/Cold Runner Design Software Ug/CAD/PRO-E Installation Fixed Certification ISO Standard HASCO Customized Customized Transport Package Wooden Case Specification 45#, P20, H13, 718, 2738, NAK80, S136etc. Trademark UK Origin China HS Code 8480719090 Production Capacity 300 Sets/YearProduct Description

Product Description:With the acceleration of the pace of modern life, simplicity and convenience have become the mainstream style of society. Many plastic food container mould produced by U-KNOW MOULD can meet people's needs. Applications range from small to large, from round, square to oval. At the same time, we also produce thin-walled container molds of different sizes. We provide high quality and low cost mold products through the latest technology system.

| Mould name | Plastic Food Container Box Mould |

| Product material | PP, PC, PS, PE, PU, PVC, ABS, RUBBER,SILICON, etc |

| Mould Steel | P20,45#, 50#, H13, 718, 2738, NAK80, S136, SKD61 etc. |

| Hardness of steel | HRC33-38 |

| Mould base | LKM,HASCO,DME...etc |

| Mould cavity | Single&multi |

| Spruce System | Pin-point , Sub-gate , edge gate , spruce gate , direct gate |

| Ejector System | Stripper Plate, Ejection Block, Ejectors Pins,gas,Cylinder |

| Cycle Time | 35~45 seconds/shot |

| Tooling lead time | 60 days |

| Runner system | Hot&cold |

| Mould life | 300,000-5,000,000 shots |

Our Advantages:

1.Capacity: Your design

2.good quality and competitive price

3.various color to choice

4.blow molding processing

5.Logo and label can be printed

6.OEM is available,we can also manufacture products according to your picture or samples.

Our Services:1. Mould Material Q/C a) mould steel checking (hardness,flaw detection) b) mould spare parts checking (hardness,size)

2. Mould making process Q/C a) design checking (part design,mould design, mould engineering drawing) b)mould size checking (according to drawing) c)mould testing (check mould, working,sample)

Company Introdution:

TAIZHOU U-KNOW Mould Co.,Ltd is an enterprise specialied in designning and manufacturing the various kind of injection moulds.U-KNOW MOULD provide the moulds and the plastic products to lots of areas all over the world,such as Southeast Asia,Middle East,Russia,Brazil,Poland,Romania,etc.

U-KNOW MOULD owns strong research & develop team and full set production equipment:professional CAD/CAM computer aided design system,Multiple specifications high speed CNC maching center,Closing service,Mirror EDM,Drilling machine,Flat grinder and 120T-2100T injection machines.U-KNOW MOULD has passed ISO9001 certification and has a number of design patents.In recent years,U-KNOW MOULD focused on developing,researching,designing and production of integral molding mould with gas assited injection,which has won praises from customers.

Our company sincerely welcomes new and old clients for consultation and cooperation!

Our Sample Room:

Packaging & Shipping

Packaging Detail: 1. Mould surface of core and cavity will be covered by antirust 2. The mould surface will be covered by butter 3. The mould will be packed by plastic membrane 4. The mould will be put into wooden case 5. Some other spare parts will be put into the wooden case together with mould, there are lifting bolt, water nozzle, water hose. Ejector-pin etc.

If you have any question please feel free to contact me,thank you.