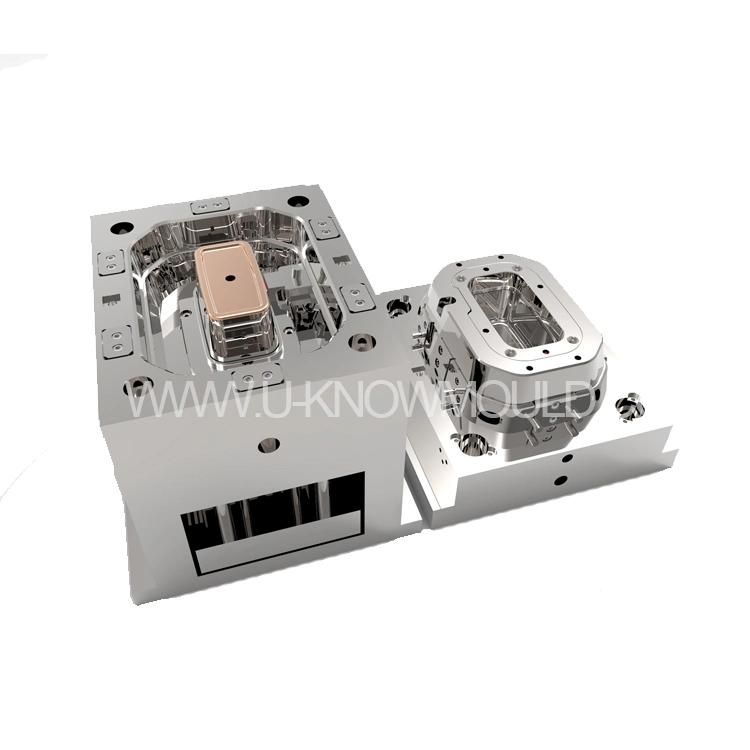

Plastic Food Container Mold/Plastic Container Mould

TAIZHOU U-KNOW MOULD CO., LTD.- Process Combination Type:Single-Process Mode

- Plastic Material:PP, PC, PS, PE, PU, PVC, ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Commodity, Home Use

Base Info

- Specification:45#, P20, H13, 718, 2738, NAK80, S136etc.

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot,Cold Runner

- Model NO.:UKC006

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:300 Sets,Year

Description

Basic Info.

Model NO. UKC006 Runner Hot/Cold Runner Design Software UG Installation Fixed Certification TS16949, CE, ISO Standard HASCO Customized Customized Transport Package Wooden Case Specification 45#, P20, H13, 718, 2738, NAK80, S136etc. Trademark UK Origin China HS Code 8480719090 Production Capacity 300 Sets/YearProduct Description

Product DescriptionWith the acceleration of the pace of modern life, simplicity and convenience have become the mainstream style of society. Many plastic food container mould produced by U-KNOW MOULD can meet people's needs. Applications range from small to large, from round, square to oval. At the same time, we also produce thin-walled container molds of different sizes. We provide high quality and low cost mold products through the latest technology system.

| Mould name | Plastic Food Container Box Mould |

| Product material | PP, PC, PS, PE, PU, PVC, ABS, RUBBER,SILICON, etc |

| Mould Steel | P20,45#, 50#, H13, 718, 2738, NAK80, S136, SKD61 etc. |

| Hardness of steel | HRC33-38 |

| Mould base | LKM,HASCO,DME...etc |

| Mould cavity | Single&multi |

| Spruce System | Pin-point , Sub-gate , edge gate , spruce gate , direct gate |

| Ejector System | Stripper Plate, Ejection Block, Ejectors Pins,gas,Cylinder |

| Cycle Time | 35~45 seconds/shot |

| Tooling lead time | 60 days |

| Runner system | Hot&cold |

| Mould life | 300,000-5,000,000 shots |

Our Advantages

1.Capacity: Your design

2.good quality and competitive price

3.various color to choice

4.blow molding processing

5.Logo and label can be printed

6.OEM is available,we can also manufacture products according to your picture or samples.

About Us

Sample Room

Packaging & Shipping

Packaging Detail:

- Mould surface of core and cavity will be covered by antirust

- The mould surface will be covered by butter

- The mould will be packed by plastic membrane

- The mould will be put into wooden case

- Some other spare parts will be put into the wooden case together with mould, there are lifting bolt, water nozzle, water hose. Ejector-pin etc

FAQ

1.

Q: how to contact with me in effective way?

A:you can contact me on Skype,QQ,Email,whatsapp wechat ,alibaba online TM

also send inquiry with 3D drawing or 2d drawing ,or original sample with size ,and tell us your details requirements ,like needs to use what material,mould need to make how many cavities ,etc.

2.

Q: How do you pack the china plastic mould?

A: We pack the plastic mould with wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any

movement.

3.

Q: What kind of steel do you use for plastic moulding?

A: We can use any type of steel appointed by customer or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

4.

Q:Your payment & shipment?

A:Payment:L/C, T/T; Shipment :DHL, TNT or by sea-shipment.

5.

Q:How long do you need for making my parts?

A: We have always been dedicated to providing our clients with a rapid prototyping service.As usual, 3-5 days is OK.

It will mainly depends on the quantity you need and processing way you prefer.