Hight Quality Industrial Plastic Fan Part Mould and Production

Green Vitality Industry Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Heat Treatment

- Application:Household Appliances, Furniture, Commodity, Electronic, Home Use

Base Info

- Specification:As per request

- Transport Package:Ply Wood Box

- Mold Life:300, 000 to 1, 000, 000 Shots

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:gv-mold

- Trademark:GVI

- Origin:China

- HS Code:8480710090

- Production Capacity:500 Sets ,Year

Description

Details of mouldName Description Mould Material NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc Product Material PP, PE, PC, PA, PS, PU, PVC, PMMA, ABS etc Cavity No. Single or multi System Of Runner Hot runner, Cold runner, Pin-point gate, Submarine gate, etc Ejector Type Ejector pin, Air gate, Ejector plate, Hydro-cylinder, etc Term Of Mould Production 15days- 60days Guaranteed Number Of Cycles 300, 000-3, 000, 000 closing Mould Design Software Ug, Proe, Solidworks AotoCAD, Moldflow, ect

Company Introduction

Green Vitality Inductry Co., Ltd is a professional injection mold maker extablished in 1993. We have been delicated to the mold making industry for 25 years.

Green Vitality has accumulated rich experience and build up a strong steady engineering and manufacturing team, which supports us to become a reliable supplier as well as the strategic partner of customers worldside.

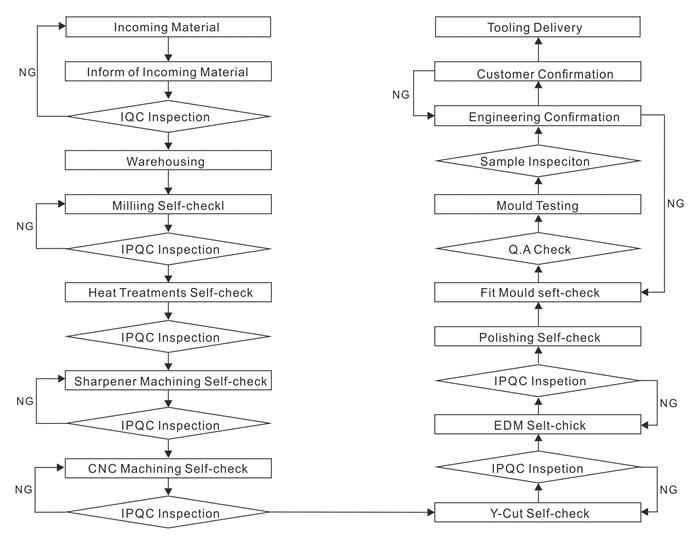

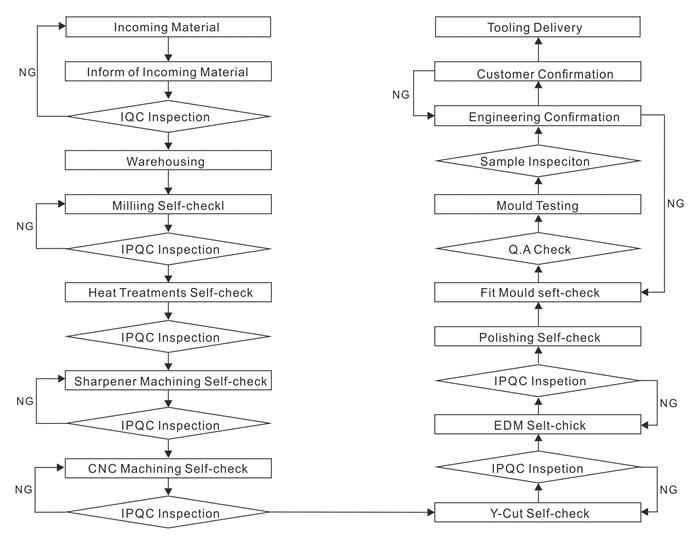

Mould Produce Process1 Product Design Customer send us the product drawing directly or we draw the product according to the

sample, then we send customer the product drawing to confirm 2 Mould Design We' ll start to design mould after the product drawing confirmed, then send customer the

mould drawing to confirm 3 Mould Making The mould start to make after the mould drawing confirmed, the process include

prepare steel, rough cut, finish machining, assembly etc 4 Mould Test we' ll test the mould after mould assembly, then we' ll send customer samples and

video of mould test to confirm 5 Final Process The mould start to polish if the sample is ok, and make grain, nitridation or chroming if

customer required 6 Mould Test We' ll test the mould again after polishing, then send customer the final sample and

video of mould test to confirm 7 Mould Packing The mould stard to pack with wooden case after the final sample confirmed, then

the mould will be sent to port and waiting for shipping

Sincere Invitation:

Welcome your visit our company.

It's our pleasure to work together with you to provide the value added service and help to make the optimum mold solution and products.

Any more information about our company and products, pls feel free to visit:

http://greenvitality.en.made-in-china.com

Should you have any plastic mould projects, welcome to send us the 2D/3D files and specification.

We will quote our best terms for you ASAP!

Company Introduction

Green Vitality Inductry Co., Ltd is a professional injection mold maker extablished in 1993. We have been delicated to the mold making industry for 25 years.

Green Vitality has accumulated rich experience and build up a strong steady engineering and manufacturing team, which supports us to become a reliable supplier as well as the strategic partner of customers worldside.

Mould Produce Process

sample, then we send customer the product drawing to confirm

mould drawing to confirm

prepare steel, rough cut, finish machining, assembly etc

video of mould test to confirm

customer required

video of mould test to confirm

the mould will be sent to port and waiting for shipping

Sincere Invitation:

Welcome your visit our company.

It's our pleasure to work together with you to provide the value added service and help to make the optimum mold solution and products.

Any more information about our company and products, pls feel free to visit:

http://greenvitality.en.made-in-china.com

Should you have any plastic mould projects, welcome to send us the 2D/3D files and specification.

We will quote our best terms for you ASAP!