Customized Plastic Injection Mould Factory/Supplier/Manufacturer/OEM/2K/3K/Double ...

Dong Guan Shi Li Jian Precision Mould Manufacture Co., Ltd.- Plastic Material:PA66+GF

- Mould Cavity:Multi Cavity

- Surface Finish Process:Heat Treatment

- Shaping Mode:Injection Mould

- Warranty:3 Years

- Process Combination Type:Compound Die

Base Info

- Transport Package:Plywood Case

- After-sales Service:Long-Term

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, ISO

- Installation:Mobile

- Design Software:UG

- Runner:Hot Runner

- Application:Industrial

- Origin:China

- HS Code:8480719090

- Production Capacity:600 Sets,Year

Description

Strong Design team

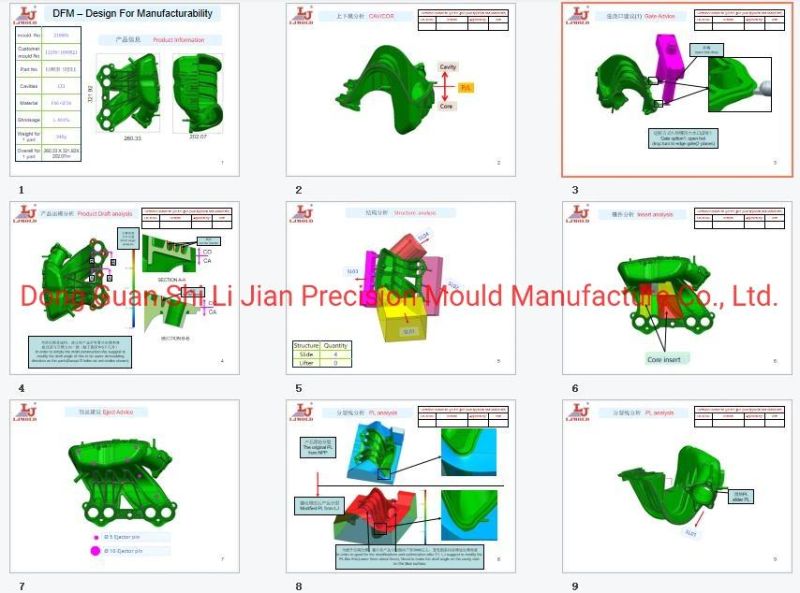

DFM- Design For Manufacturability

Design study - Project Management

High Speed CNC machining center

Professional polishing

Mold fitting (3 groups in Assembly room)

Sampling Room-23 sets Injection machines (60T~3000T)

Final inspection prior to mold shipping

Painting per customer request and packing

Deliver to Shenzhen port base on FOB terms

FAQ

1-Where are your molds exported?

Most of our molds are exported to USA, Canada,Germany,Czech,France, UK and so on.

2-How long do you evaluate the price after you receive the RFQ?

Normal we provide the quotation to the customer in three working days; if the project is very urgently, then we will try our best to provide it within one day.

3-What kind of requirements do you need when making a quotation?

For mould manufacturing

2D/3D Part Drawing,Cavity number, Type of Hot runner and No., Type of mold steel, standard(ie.DME, Hasco etc), Plastic material in uses, any special design enquired from customer

For production (in house mould)

Annual production amount, Plastic material details; Inspection requirements.

For production (mould transfer from customer)

2D part drawing with detail dimension shown, Mould drawing, Plastic material details, Part and runner weight, Mold age, Cycle time, Samples, Inspection requirement, other special requirements.

4-What type of software do you use?

We are using Pro-E, UG ,CAD and so on.

5-How many days do you work per week?

We are working 6 days per week. CNC, EDM and Polishing Departs, two shifts. 10H/shift. Mold shop depends on the emergency.

6-What's property of your company?

Private factory.

7- What materials are you molding most often?

ABS, PP, PC, PA, PA6+GF,PVC,POM, PBT, PPO, PE, TPE, U-PVC, and so on.

8 - What type of formats do your mold drawings use often?

We often use .dwg, .step, .prt and .igs also.

9 - What kind of hot-runner do you use?

Usually we use Mold-Master,Synventive, Incoe, YUDO, Hasco, HRS,D.M.E., Husky and so on.

10-What kind of services will you do when you ship the mold?

About the Ex-factory moulds, we will provide the following services before shipping.

1). We will pack the mould with an insecticidal wood case, and fix it with iron frame.

2). We will put the electrodes and the spare parts which are easy damaged into the wood case together.

3). We will send all the related drawings of Mould, Data and Steel Certifications together with the moulds.

11- Do you provide the testing samples for free?

We supply 5~10 pieces samples to customer for free, but the freight is collected. Totally about 3 times of testing, it is up to the part structure.

12-What will you do if your mold has the quality problem after shipping to the customer?

First, we will check the problem and analyze all kind of reasons. If it is our fault, we will pay all the cost without any bargain or remake the new component or mold to the customer. If it is both problem, then both take the responsibility. If it is the customer's problem, then the customer should take it.