Plastic Injection Mould Tooling for Distribution Box Cover

Wenzhou Outeng Precision Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:PC

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Electronic, Home Use

Base Info

- Specification:CE

- Transport Package:Wooden Case

- Delivery Time:50days

- Material:S136 H13lkm

- Mould Life:1 Million to 3 Million

- Quality:High Quality

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:OT19020

- Trademark:Outeng

- Origin:China

- HS Code:8480719090

- Production Capacity:500 Sets , Year

Description

Basic Info.

Model NO. OT19020 Runner Cold Runner Design Software Pro-E Installation Fixed Certification CE, ISO Standard HASCO Customized Customized Quality High Quality Mould Life 1 Million to 3 Million Material S136 H13lkm Delivery Time 50days Transport Package Wooden Case Specification CE Trademark Outeng Origin China HS Code 8480719090 Production Capacity 500 Sets / YearProduct Description

Wenzhou Outeng Precision Mould Co.,Ltd is specialize in all kinds of plastic precision moulds,such as:wall switch&socket mould,MCB mould,electronic mould,auto parts mould,small fittings mould,hardware mould,injection parts,brass and accessories.We do OEM and have equip our own design team,all moulds are manufactured by high precision process.The mould steel is S136,H13 or SKD61 which can ensure mould life at least one million shots.

Company has much experience on making mould and exporting mould with brass to South Asia,Middle East countries and Africa and so on.

Mould details:

1. Design 3D drawing for customers' confirmation according to their 2D drawing or sample when placing to order.

2. Mould Matieral: Different grade: P20, S136, 2316, H13, etc.

3. Surface treatment: mirror polish, polish, texture,matte

4. Independent temperature control & heating system Which boasts an even heating temperature and keeps product with reliable and stable quality.

5. Mould life: more than 1 million shots

All inserts can be interchangable.

6. Product matieral: ABS, PC, PE, PMMA, POM, PP, PBT, PSU, PVC, PA6, PA66+GF,ect

7. Quick delivery time: 25-60 days

Any kind of plastic precision moulds are available:

| 1 | Sample or 2D drawing from customer |

| 2 | Build 2D and 3D drawing |

| 3 | CAD mould design |

| 4 | Parts inspection / CNC machining / EDM machining |

| 5 | Mould assembly |

| 6 | Mould test |

| 7 | Sample confirmation by buyer |

| 8 | Dilver the mould and goods |

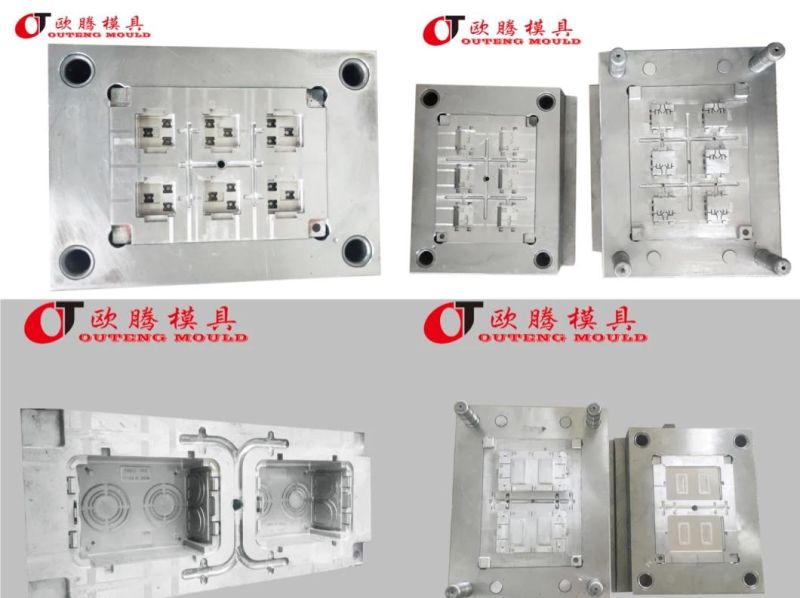

Mould photos

Goods delivery and office&workshop photos

Mould process and machining

Why choose us:

1. Good quality with Resonable price

2. Have rich experience on design and mould manufacturing!

3. We will send you quotation asap after getting your inquiry.

4. Preparing mould material in advance and complete mould on time.

5. Working report will be sent every week to let you know goods progress.

6. Sending trial samples freely to customer for confirmation.

7. Packing mould and prepare everything well for mould shipment.

8. Offering free inserts/parts/switching gate/technical guidance to customer.

9. Hardworking, Sincerity, Honesty, Responsibility is our personality.

How to reach our company Wenzhou?

1.From Ningbo by train 1.5 hour.

2.From Yiwu by train 2 hours.

3.From Shanghai by train 3.5 hours.

4.From Guangzhou by air 1.5 hours.

Welcome To Visit Our Company and Inquiry Us! Customer Demand is Our ongoing motivation!