Tooling Maker Flashlight Shell Plastic Part Injection Mold Making and Molding

Dongguan Cheng Kang Mould & Plastic Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Electronic, Home Use, Hardware

Base Info

- Specification:55*55*187mm

- Transport Package:PE Plastic Packaged in Carton

- OEM:OEM

- Weight:48.7g

- Customized:Customized

- Standard:Lkm

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Trademark:Customized

- Origin:Dongguan China

- HS Code:84804100

Description

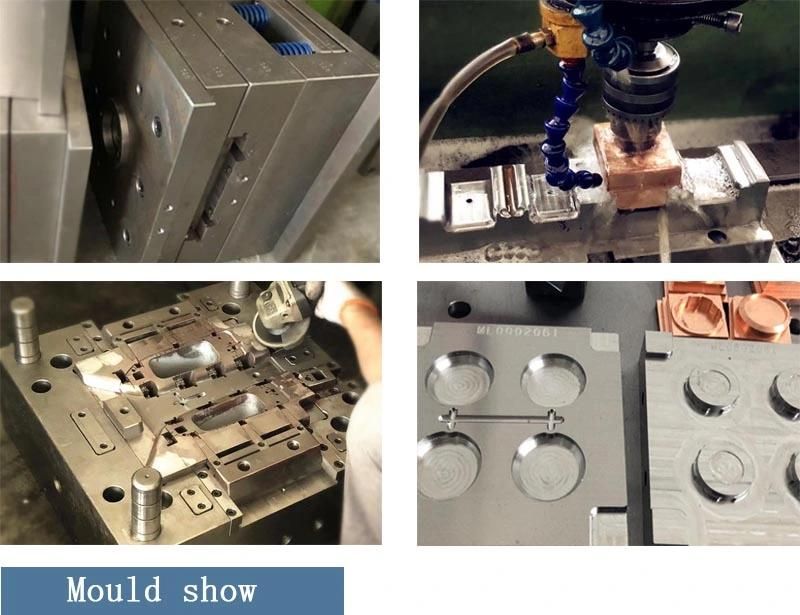

1) First-rate facilities:

1) First-rate facilities:Mould Machine: 2 Mould Machines,4 EDM Machines,1 High Speed CNC Carving and Milling Machine,

7 Milling Machines and 3 Grinding Machines

Plastic Injection Machine:10 Plastic injection molding machine,6 Precision injection molding machine

2) Professional Working Team:

Mould Desin Department: We have a R&D Team including more than 5 engineers with excellent design

abilities over 20years.

Mould Production Department: Over 10 experiened workmen in charge of our factory's mould production.

Plastic Injection Production Department:1 supervisor,2 workshop foreman,2 QC,1 material purchaser and group of worker

to produce and self-check plastic injection products.

Office: Over 10 experiened employees in charge of our company work affair.each one is

responsible for specialized job.

3) Supply "one-stop" service

4) All of our operations are strictly compliant with ISO 9001: 2015 guidelines.

5) Strict quality control systems

6) Short lead time.

7) Perfect package for export.

8) Superior after-sales service

We hired 90 employees to work out products and moulds for our clients,with our experiences and profession,we bought 40 injection machines and OEM/EDM manchine,that can make kinds of plastic mould and parts,would produce your products efficient and quality.we can produce electronic plastic parts,medical plastic parts,plastic boxes,home plastic appliance,etc.

we worked with plenty of international clients,like zeiss,keylite,ysl,etc.Due to our allegiance and capacity, most of them still have commercial trade with us.

Our factory is near by Shenzhen port in 1h20mins,we can delivery products to clients timely.

FAQ

FAQQ: What is your business scope?

A: Our company mainly produces plastic mould and injection plastic parts

Q: What industries do your products mainly cover?

A: In the past 20 years, we have developed and manufactured moulds including electronic products, furniture, lighting products, daily necessities, medical equipment, engineering equipment, etc.In recent years, the intelligent technology industry has been on the rise, at the same time, we have received a lot of product demand for intelligent technology and mold development.

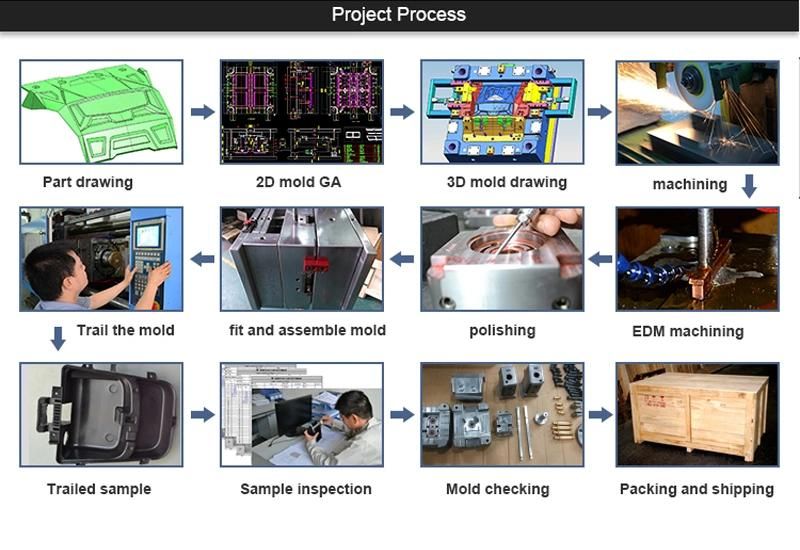

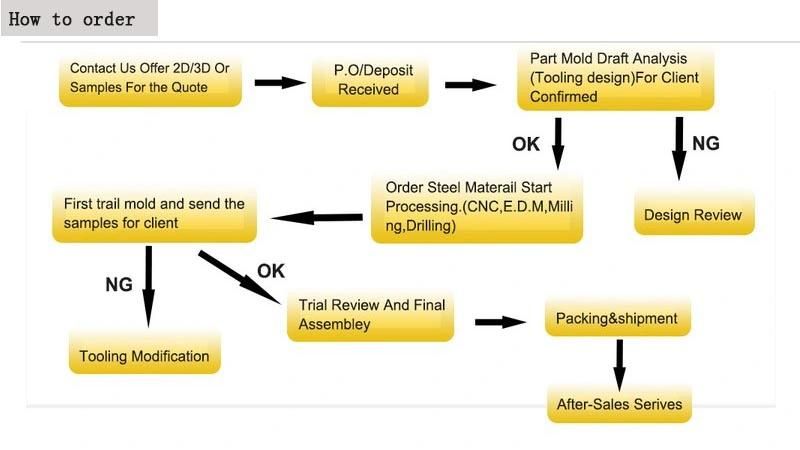

Q: What is the processing for Mold inquiry and quote?

A: If you are going to make an inquiry of mold, please give us the basic information with 3D drawing or 2D drawing or any other detail information(material, part weight, qty, etc), and we will give you answer within 24hours .

Q: Which countries do you often work with?

A: Our customer groups include: USA, Germany, Italy, Portugal and China ETC

Q:What successful programs have you had?

A:We have provided die manufacturing work and injection molding work for many world famous enterprises such as

Electrolux,Bondi, Nokia, Chase and Bentley, and have achieved great success cooperation with them.

Q:What are the main ways of transporting the products?

A: We have a number of cooperation international logistics, DHL, Fedex, SF Express, etc., before the goods delivered we will strict packaging products to ensure the goods would reach the destination safely.