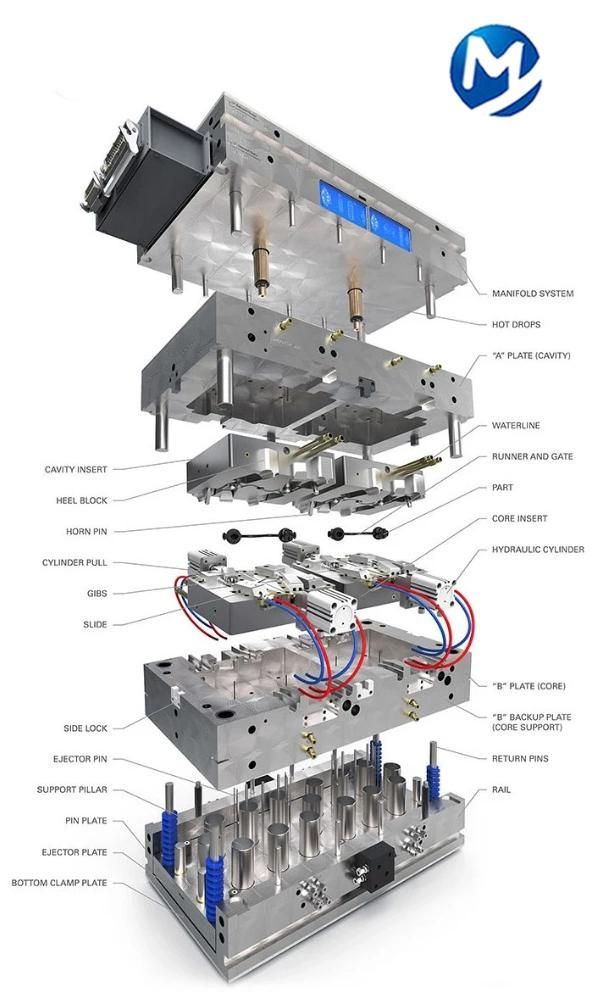

OEM Plastic Injection Molding for Charging Points

Shanghai MY Mould Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Surface Finish Process:Electroplating

- Shaping Mode:Injection Mould

- Application:Furniture, Commodity, Electronic, Home Use

Base Info

- Specification:30X40X30cm

- Transport Package:Cases

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:A0008

- Trademark:MY MOULD

- Origin:Shang Hai

- HS Code:8480300000

- Production Capacity:200PCS,Year

Description

Mould material

P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc....

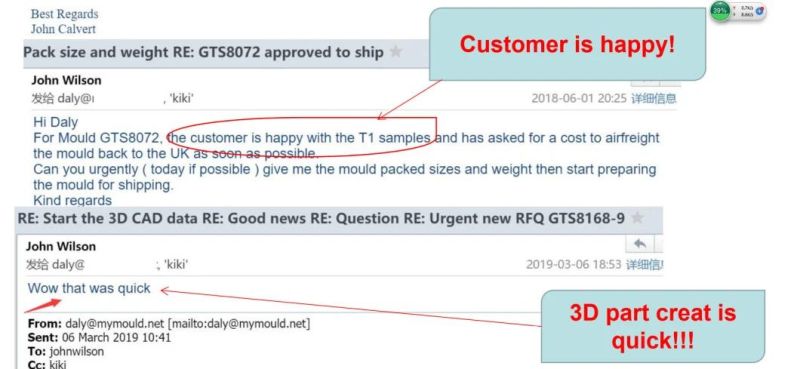

Fast mould design

can be within 1-3 working days after getting customer's drawings

Lead time

3- 6 weeks after getting the mould design confirmation

Mould testing

All of the moulds can be well tested before the shipments.Videos for testing the moulds are available.

Minimum order

small orders can be accepted.

Production capacity

50 sets/month

Port

shanghai

Runner

Hot/cold

Payment terms

L/C T/T Western Union Money Gram.

Mould making service

OEM/ODM service available.

After sales service

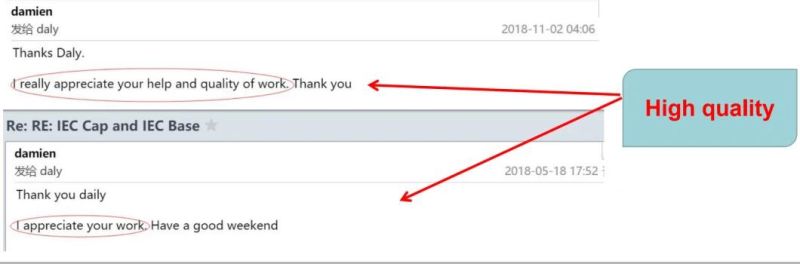

Available by our staff with more than 15 years of working experience in this field.

Good packages

In strong wooden pallets to avoid any damages during the long transportation.

FAQ:

Manufacturing and exporting experience for over 10 years. ISO 9001 approved &TS16949 approved .

Products are supplied to over 50 countries.

One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

In-house mold design and building capabilities.

No reclaimed material used to ensure high quality.

Keep secret to your idea and your design.

24 hours (two shifts) / 6 days for production.

Professional design team, mold maker engineer. OEM/ODM service.

Professional QC and R&D teams to assure high quality.

Professional sales team. Good English capabilities and communication skills.

No MOQ.

Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.

Geographical advantages: within 30 minutes to airport or sea port.