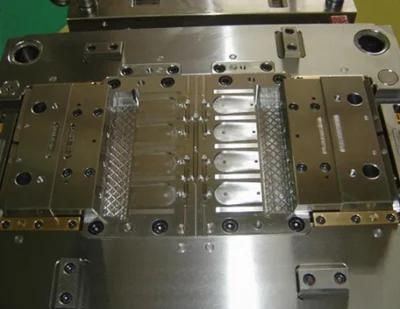

Plastic and Metal Injection Mold

Hebei Dechuang Chemical Equipment Co., Ltd.- Mould Cavity:as Customer′s Need

- Surface Finish Process:as Customer′s Need

- Shaping Mode:Injection Mould

- Warranty:Yes

- Plastic Material:as Customer′s Need

- Process Combination Type:Single-Process Mode

Base Info

- Mould Sizes:15*15-200*200cm Available

- Mould Material:718h, S136h, Nak80, Ss2316 Available

- Production Stability:Only 0~0.1% Repair Rate

- Mould Standard:Misumi, Hasco, Dme Available

- After-sales Service:Yes

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:as Customer′s Need

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Model NO.:As customer′s requirement

- Transport Package:Wood Box for Transportation

- Specification:As customer′s requirement

- Trademark:DC

- Origin:Hebei, China

- HS Code:8480710090

- Production Capacity:100tons,Month

Description

Basic Info.

Model NO. As customer′s requirement Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Runner as Customer′s Need Design Software UG Installation Fixed Certification TS16949, CE, ISO, FDA After-sales Service Yes Mould Standard Misumi, Hasco, Dme Available Production Stability Only 0~0.1% Repair Rate Mould Sizes 15*15-200*200cm Available Mould Material 718h, S136h, Nak80, Ss2316 Available Transport Package Wood Box for Transportation Specification As customer′s requirement Trademark DC Origin Hebei, China HS Code 8480710090 Production Capacity 100tons/MonthProduct Description

Plastic/metal Injection MoldWe are ISO 9001: 2008 certificated manufacturer of custom plastic injection molds, molding parts, plastic injection molding, custom plastic products, custom plastic parts.

We can customize all kinds of plastic injection mold based on your drawingsspecs, product range from electronics, outdoor goods, car components, device precision parts etc, strong technical capacity is our biggest strong-point, we never leave any problem with customers after mould is exported, 0% repair rate is what we are persuing.

Our Quality Commitment:

(1) Highly production stability, almost 0% repair in mass production.

(2) Dimension tolerance exactly in ISO standard unless specified

(3) No delay with delivery date, Fineking can work with a contract with panelties for dalay per day

Why Us:

(1) Price Stability: We work with legal contracts and always give a stable price, no surprises after quoting.

(2) No Communication Problems: Our well-trained staffs are well-trained and are proficient in technical communication.

(3) Strong Technical Capacity: We can help y· Ou in product design and development for reducing production cost for you.

(4) Advanced Management: We are certificated with ISO 9001: 2008 quality management system.