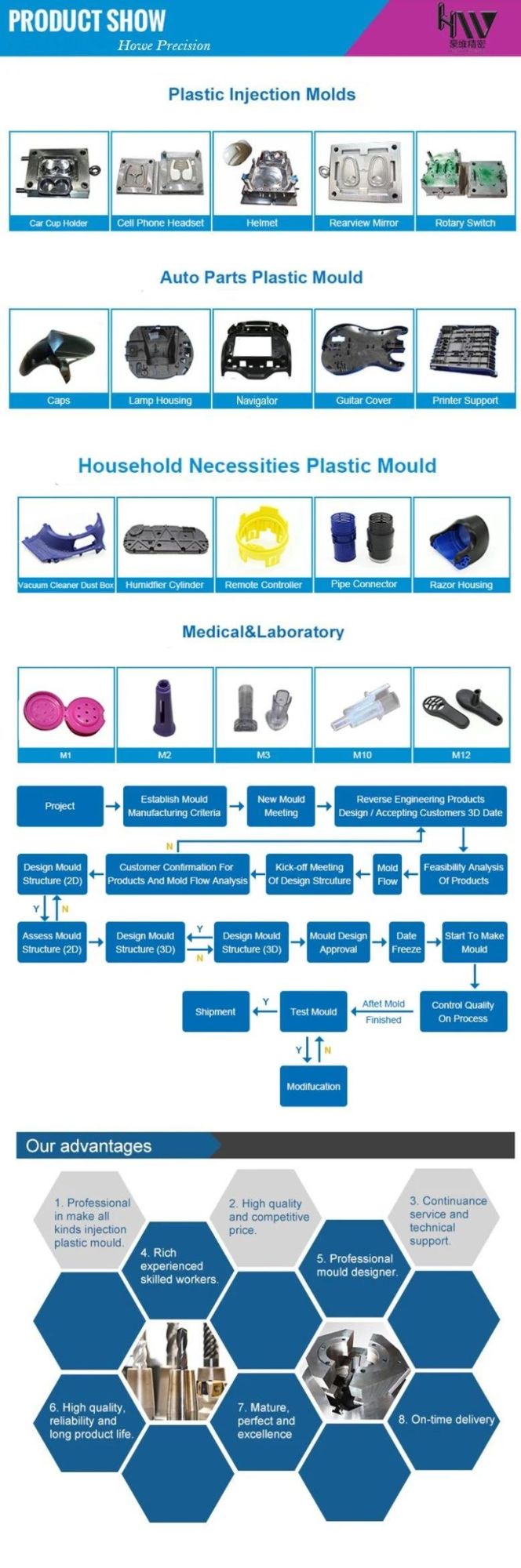

Custom Design ABS Plastic Protective Helmet Hard Hat Molded Parts Injection Moulding

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Progressive Die

- Plastic Material:PC, ABS

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Glossy or Mirror Polished, Textured

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

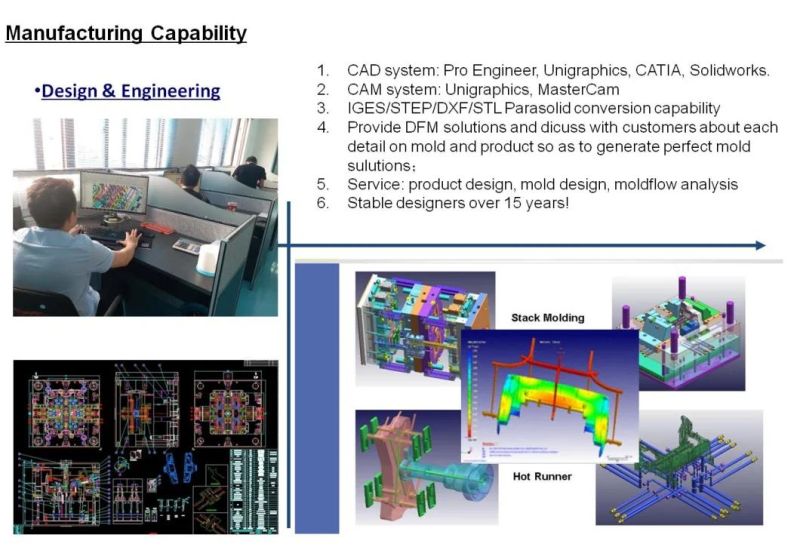

- Injection Machine:120-1200t

- Steel Treatment:Heat Treatment, Nitriding, Chrome Plating

- Mold Base:Lkm, Hasco, Dme or Upon Customer′s Requirement

- Mold Life:300,000 Shots - 1,000,000 Shots

- Ejection System:Stripper Plate, Lifter, Push Bar, Ejection Pin

- Gate Type:Fan Gate, Sub Gate, Pinpoint Gate, Valve

- Mold Material:P20,Nak80,SKD11,S316,S50c,S45c,718h,718 or Custome

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Semi Fixed

- Design Software:Ug, Autocad

- Runner:Hot Runner

- Model NO.:HW-201112-1

- Transport Package:Wooden Box for Mould, Carton for Products

- Specification:According to customers′ drawings

- Trademark:HOWE,OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:10000 PCS,Month

Description

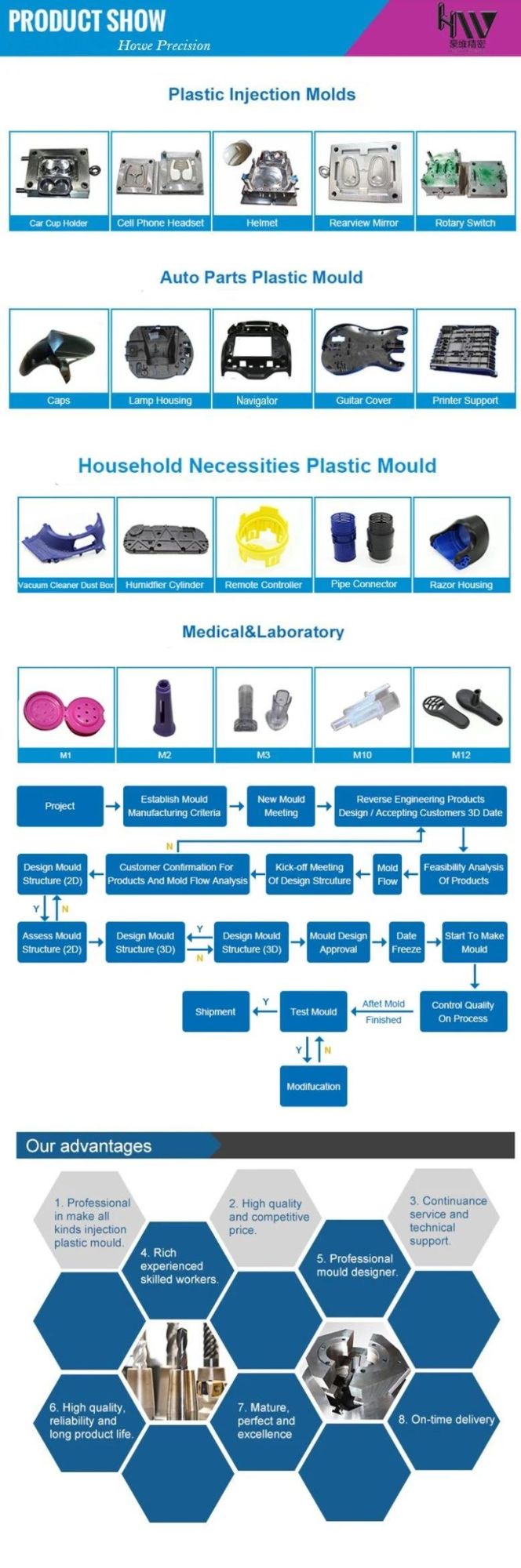

Process of making moulds1.Sample/Drawing After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis. 2.Negotiation Material, cavity, price, delivery time, payment term etc. 3.Place Order when all terms are agreed by both sides, then we will accept an order. 4.Mould Design Our R&D team will design the mould per customer requirements and send drawings for approval. 5.Tooling Mould Once the mould design is approved will start mould tooling. 6.Mould Process CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. 7.Sample Confirmation Send samples for confirmation, if not approved we will adjust the mould structure. 8.Mass Production After the customer approves the sample, we will arrange mass production. QC will inspect after products finished. 9.Package PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing. 10.Delivery By sea or by air according to customer requirement. 11.After-sales Service Ready to help customers solve any possible problems.

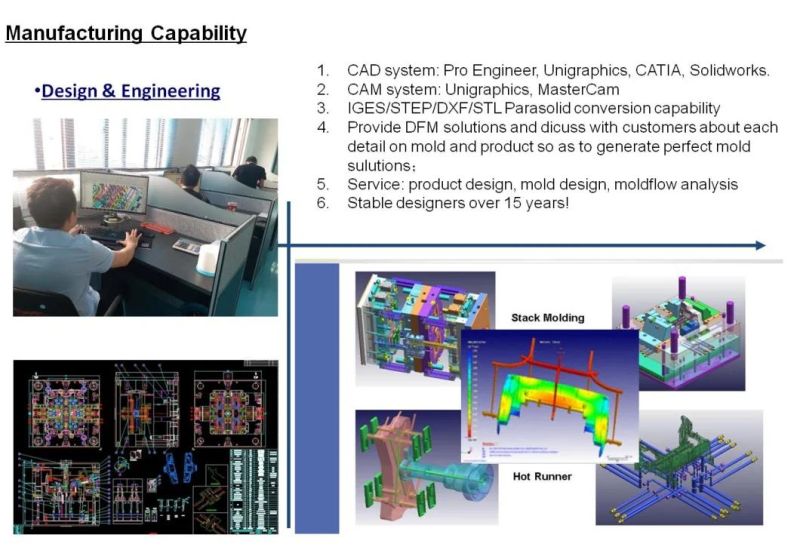

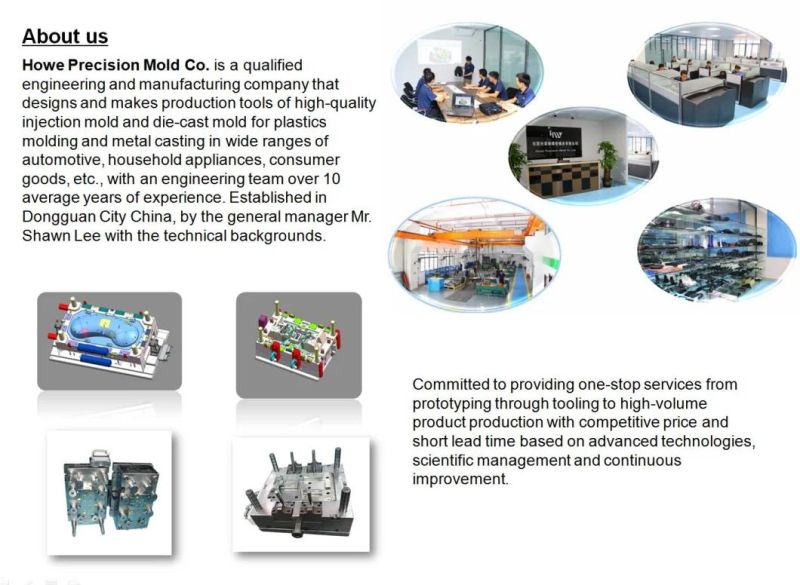

Company profile

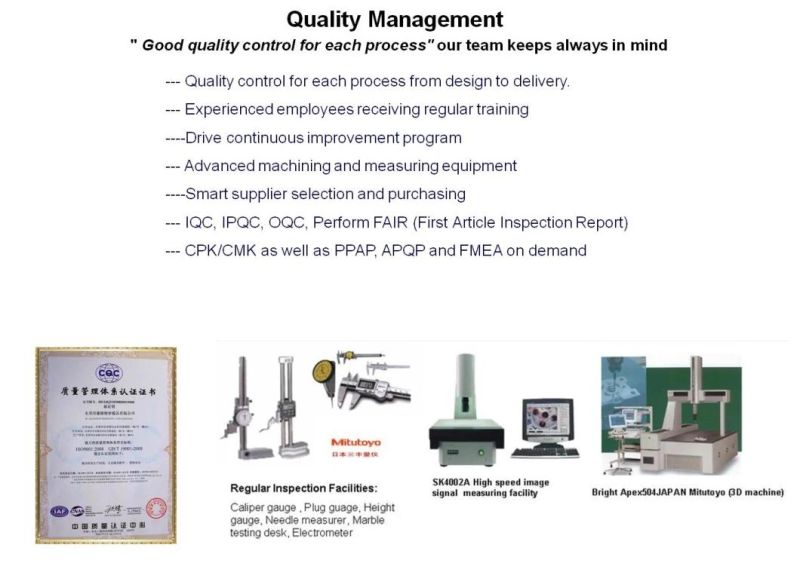

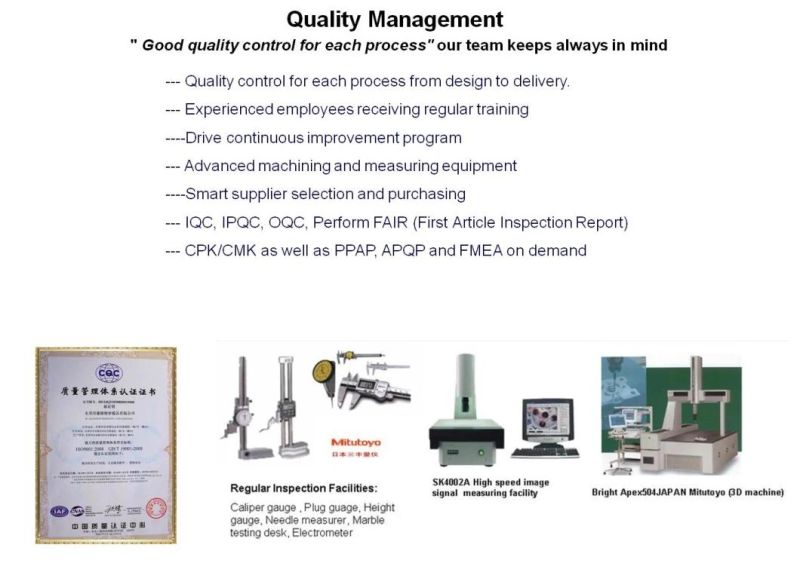

Quality Control

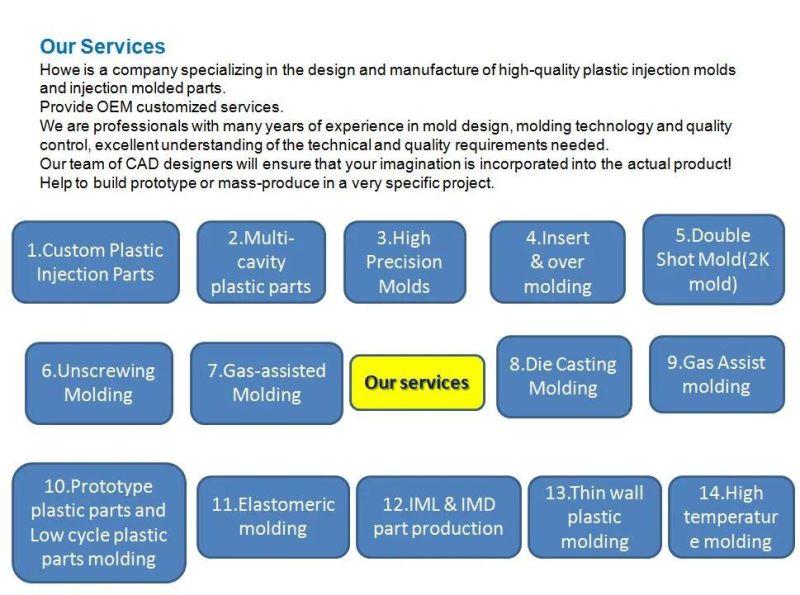

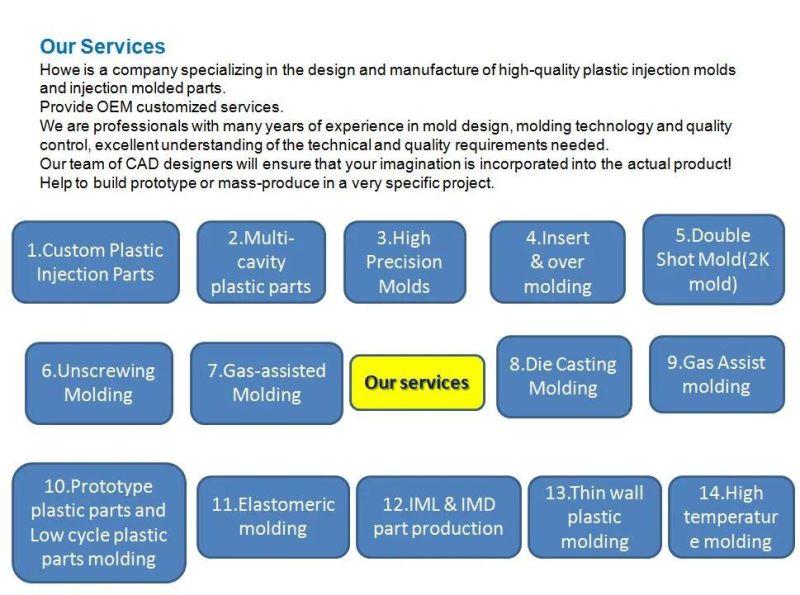

Our services

Our workshop

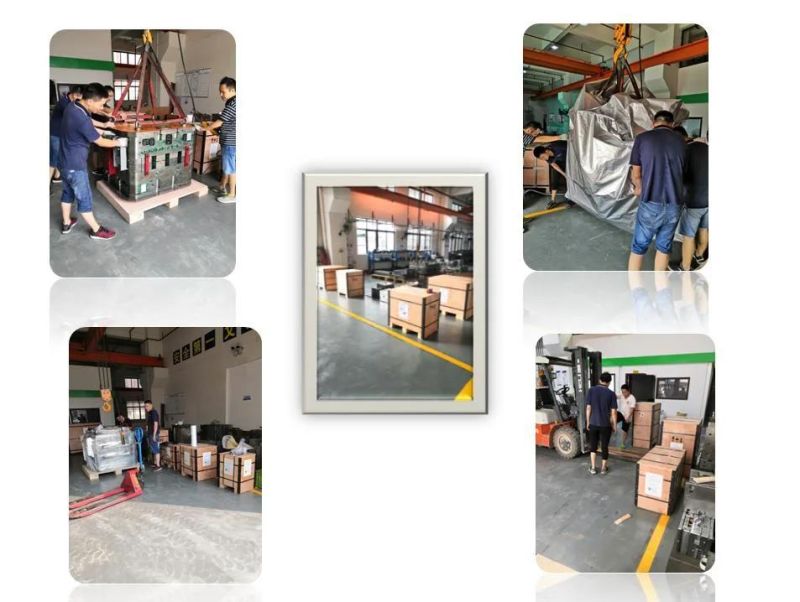

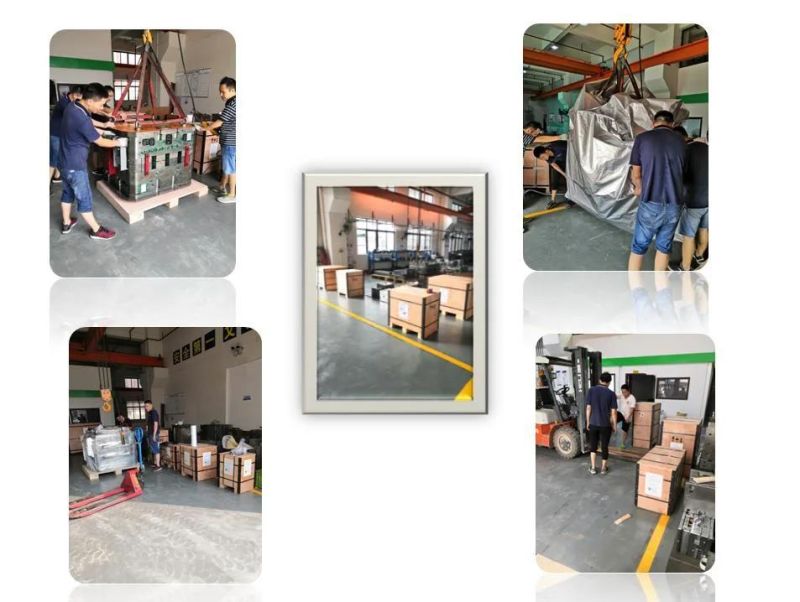

Mold Packaging

FAQ:

Q1: What kind of molds do you make?

A1: We are mainly making plastic injection mold. Sometimes we also make die casting molds according to our customer's requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems, we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q5: Can you provide the steel certificate and heat-treatment certificate?

A5: Yes, We can provide a steel certificate or hardness certificate to prove.

Q6: Can you make the texture/text / heat-treatment /nitriding for the injection mold plastic?

A6: Yes, as a plastic mold factory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold's size and complexity. Normally, the lead time is 25-45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or required by the client.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it to avoid any movement.

Company profile

Quality Control

Our services

Our workshop

Mold Packaging

FAQ:

Q1: What kind of molds do you make?

A1: We are mainly making plastic injection mold. Sometimes we also make die casting molds according to our customer's requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems, we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q5: Can you provide the steel certificate and heat-treatment certificate?

A5: Yes, We can provide a steel certificate or hardness certificate to prove.

Q6: Can you make the texture/text / heat-treatment /nitriding for the injection mold plastic?

A6: Yes, as a plastic mold factory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold's size and complexity. Normally, the lead time is 25-45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or required by the client.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it to avoid any movement.