Full Face Motorcycle Helmet Kid's Bike Safety Helmet OEM Style Injection Molding

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Progressive Die

- Plastic Material:ABS

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Glossy or Mirror Polished, Textured

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Steel Treatment:Heat Treatment, Nitriding, Chrome Plating

- Mold Base:Lkm, Hasco, Dme or Upon Customer′s Requirement

- Mold Life:300,000 Shots - 1,000,000 Shots

- Ejection System:Stripper Plate, Lifter, Push Bar, Ejection Pin

- Gate Type:Fan Gate, Sub Gate, Pinpoint Gate, Valve

- Mold Material:P20,Nak80,SKD11,S316,S50c,S45c,718h,718 or Custome

- Customized:Customized

- Standard:DME

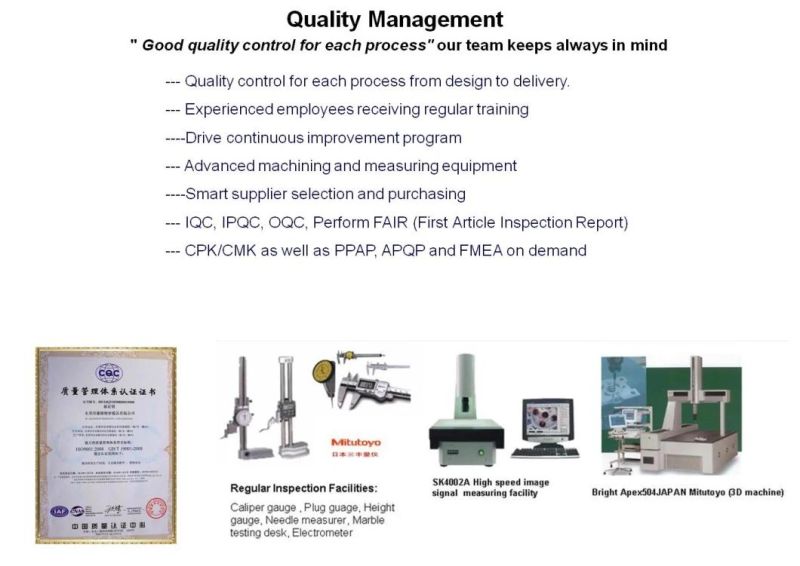

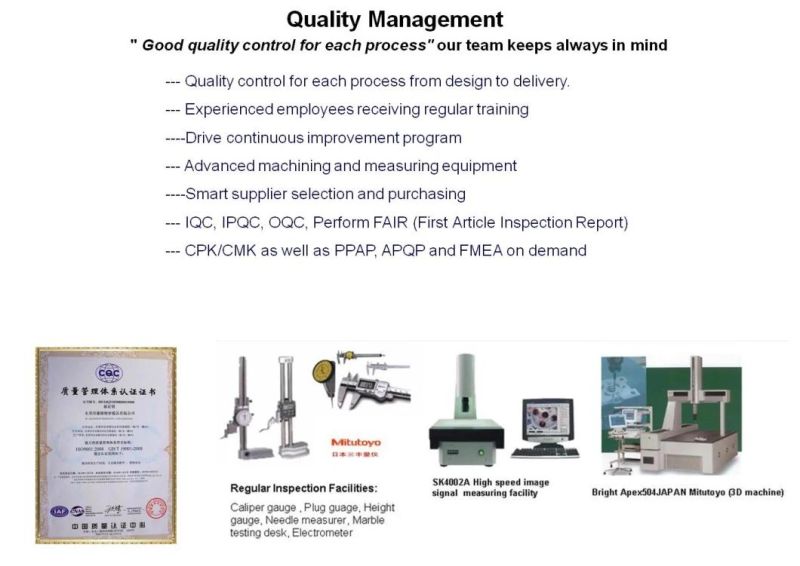

- Certification:CE, ISO

- Installation:Semi Fixed

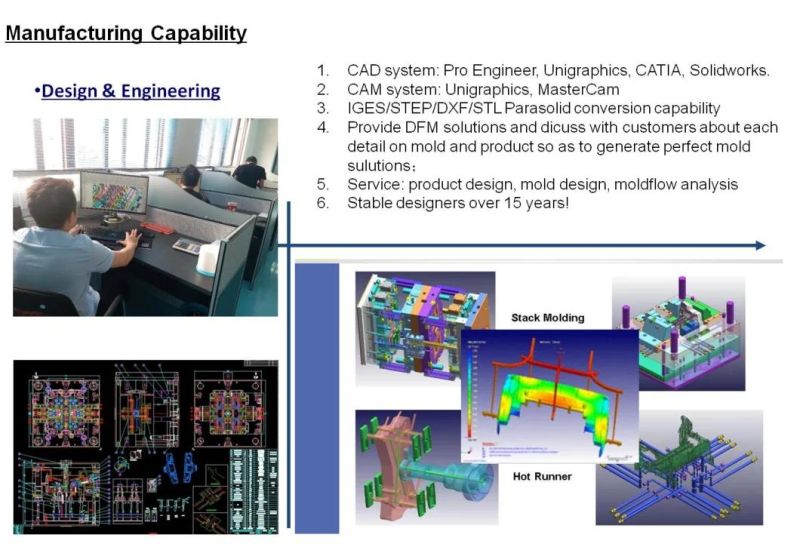

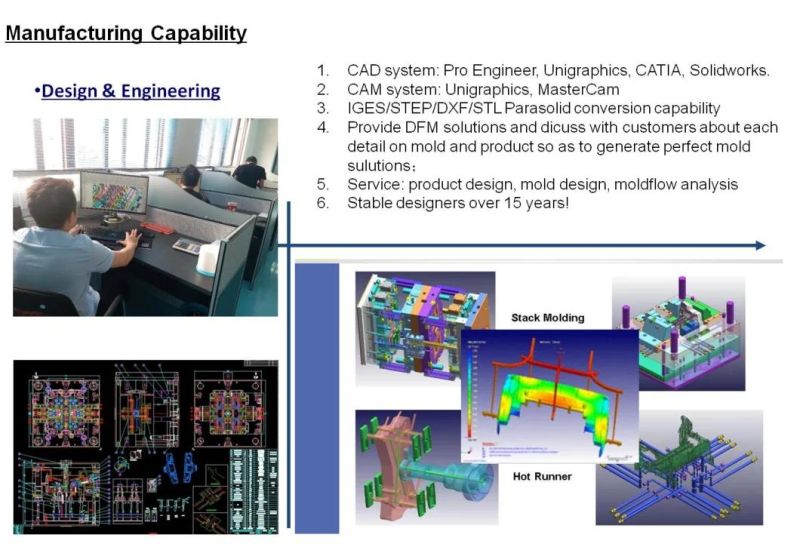

- Design Software:Ug, Autocad

- Runner:Hot Runner

- Model NO.:HW-201112-2

- Cycle Time:10-300S

- Transport Package:Wooden Box for Mould

- Specification:According to customers′ drawings

- Trademark:HOWE,OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:10000 PCS,Month

Description

Mould informtionInjection mold standard HASCO,DME,MISUMI,China lKM Standard. Please provide 2D, 3D, samples, or the size of the multi-angle pictures. Mould material 45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc. Product material ABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDPE etc. Cavity Single-cavity, Multi-cavity, or by request. Runner system Cold runner or Hot runner. Mould precision ±0.01mm. Mould Life 50-100 million shots. Software CAD, PRO-E, UG, Rhinoceros etc. Design Time 1-3 days (normal circumstances). Main technology Milling, grinding, CNC, EDM, wire cutting, carving, lathes, etc.

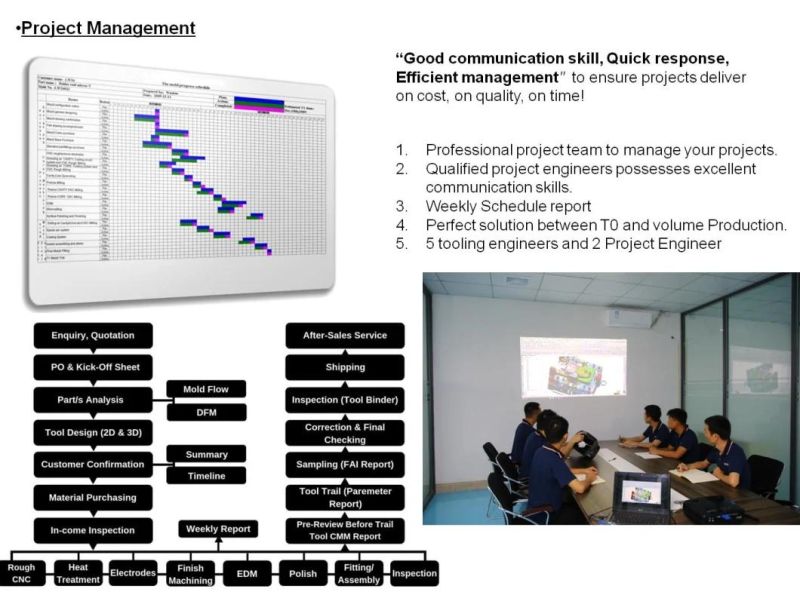

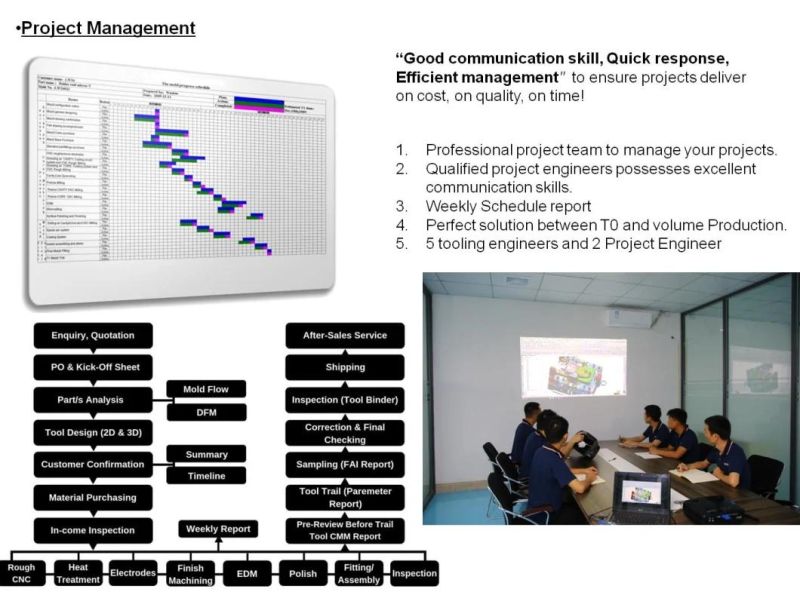

Company profile

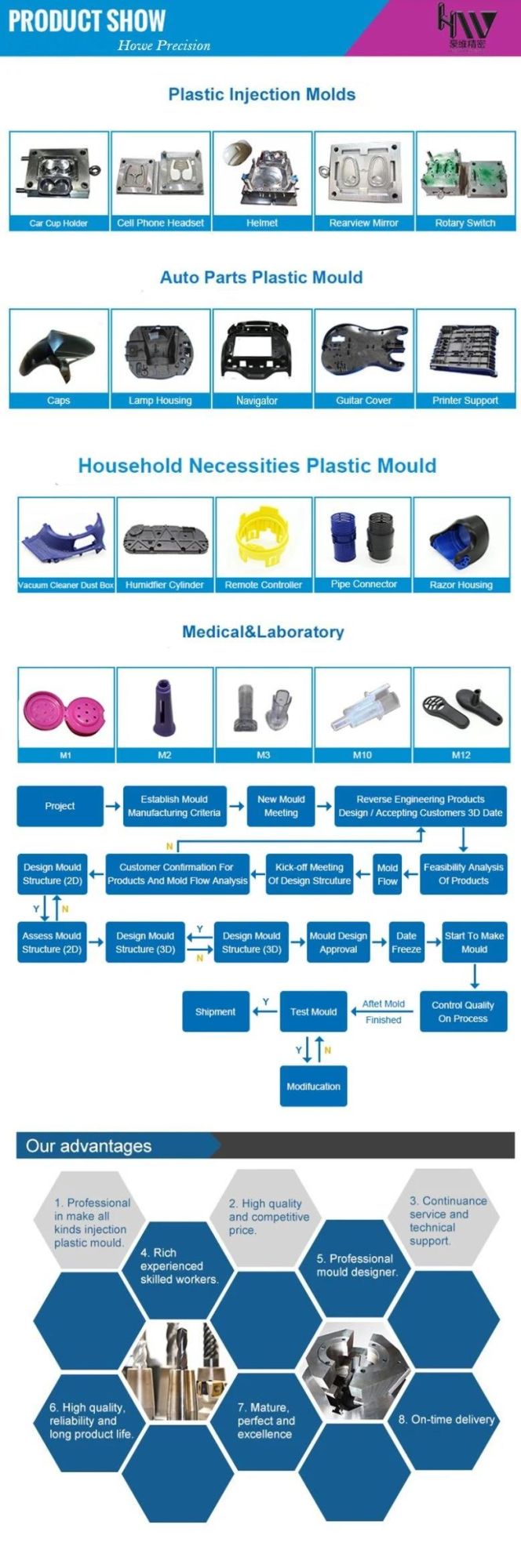

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 10 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Committed to providing one-stop services from prototyping through toolings to high-volume product production with competitive price and short lead time based on advanced technologies, scientific management and continuous improvement.

Our services

Quality Control

Our workshop

Packaging detail

FAQ:

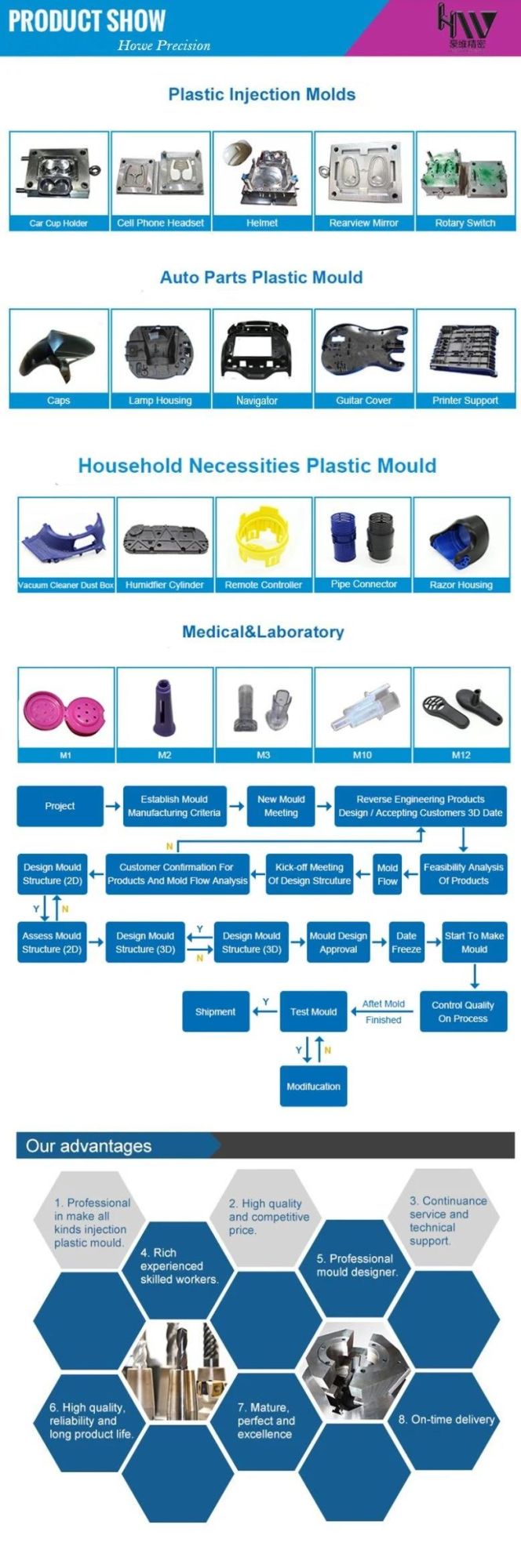

Q1: What kind of molds do you make?

A1: We are mainly making plastic injection mold. Sometimes we also make die casting molds according to our customer's requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems, we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q5: Can you provide the steel certificate and heat-treatment certificate?

A5: Yes, We can provide a steel certificate or hardness certificate to prove.

Q6: Can you make the texture/text / heat-treatment /nitriding for the injection mold plastic?

A6: Yes, as a plastic mold factory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold's size and complexity. Normally, the lead time is 25-45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or required by the client.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it to avoid any movement.

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, the weight of the product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirements. |

| 8. Delivery | deliver goods by air or by sea. |

Company profile

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 10 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Committed to providing one-stop services from prototyping through toolings to high-volume product production with competitive price and short lead time based on advanced technologies, scientific management and continuous improvement.

Our services

Quality Control

Our workshop

Packaging detail

FAQ:

Q1: What kind of molds do you make?

A1: We are mainly making plastic injection mold. Sometimes we also make die casting molds according to our customer's requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc.

The manifold recommended for your tool is selected to meet your individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems, we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q5: Can you provide the steel certificate and heat-treatment certificate?

A5: Yes, We can provide a steel certificate or hardness certificate to prove.

Q6: Can you make the texture/text / heat-treatment /nitriding for the injection mold plastic?

A6: Yes, as a plastic mold factory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold's size and complexity. Normally, the lead time is 25-45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or required by the client.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid moisture.

Third step: We put this plastic film packed mold in a wooden box, and fix it to avoid any movement.