Chemical Vapor Deposition Diamond Dies

Zhengzhou Hanguang Super Hard Tools Co., Ltd.- Shaping Mode:Grinding

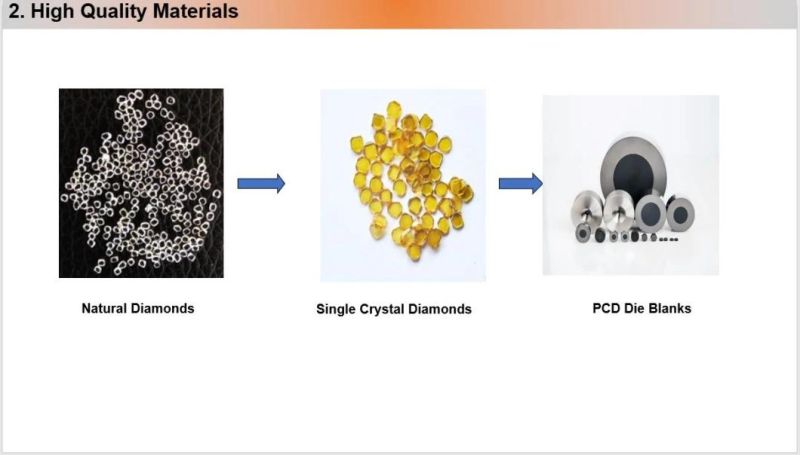

- Material:Diamond

- Type:Nano Dies

- After-sales Service:Repairing Dies

- Hole Type:Round Mould

- Cavity:Single-cavity

Base Info

- Specification:0.118"~2.362"

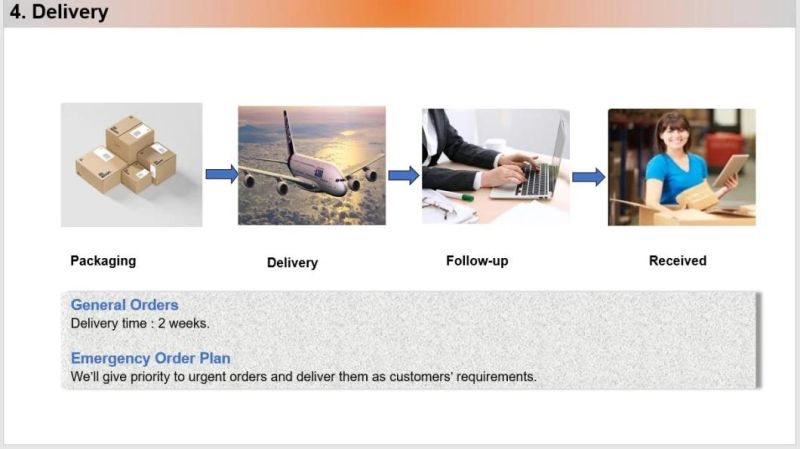

- Transport Package:Carton

- Coating:Nano Dies

- Customized:Customized

- Warranty:1 Year

- Application:Wires and Cables

- Surface Treatment:Polish

- Model NO.:1.2mm~60.0mm

- Trademark:HG

- Origin:China

- HS Code:8480419000

- Production Capacity:20000pieces,Year

Description

Nano dies have unique nanocrystalline diamond composite structures(chemical vapor deposition CVD ) to achieve significant productivity improvements.The diamond coating makes nano dies exceptional in durability and smoothness.

1.Appliable Wires

Copper,aluminum,brass,aluminum,alloys,low-high carbon and stainless steel wires and tubes.

2.Features

High cost performance.

High production efficiency.

Low friciton.

Bright wire surface.

No wear ring and scratch.

Very hard die surface.

Free of die recutting.

0% tolerance in full die life.