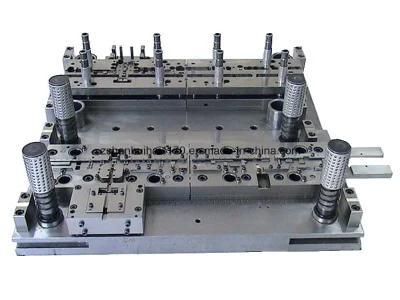

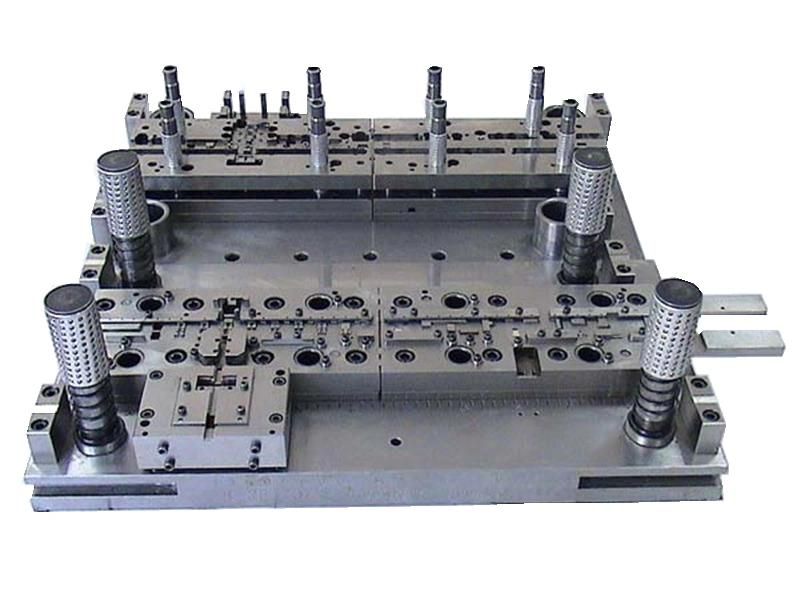

High Quality Metal Stamping Mould Stamping Part

Zhongshan Huihai Mold & Automatic Equipment Co., Ltd.- Lead Time:38 Days

- Name:High Quality Steel Stamping Mould Stamping Part

- Application:Hardware, Car, Household Appliances, Home Use

- Material:Low Alloy Tool Steel

- Packing:Wooden Case

- Customized:Customized

Base Info

- Milling Speed:Normal Speed

- Mold Cavity Technology:CNC Milling

- Driving Motor Type:Permanent Magnet

- Manufacturing Technology:Computer Technology

- Process Combination:Progressive Die

- Technics:Forming Die

- Processing Method:Punching and Shearing Mould

- Die Standard:Dayton Misumi

- Stamping Material:Stainless Steel, Aluminum Alloy, Brass, Zinc etc

- Mould Material:Cr12, Cr12MOV, DC 53, Skh-9, 45# etc

- Design Software:2,3 D, Auto CAD, Cae, PRO-E, Solidworks, Ug

- Tolerance:+-0.01mm

- Model No:Hh111

- Model NO.:HH111

- Parts Detection Method:Measurement of Three Axis NC

- Transport Package:Wooden Case

- Specification:SGS, ISO

- Trademark:huihai auto

- Origin:Zhongshan

- HS Code:8207300090

- Production Capacity:500 Sets , Year

Description

Basic Info.

Model NO. HH111 Model No Hh111 Tolerance +-0.01mm Design Software 2/3 D, Auto CAD, Cae, PRO-E, Solidworks, Ug Mould Material Cr12, Cr12MOV, DC 53, Skh-9, 45# etc Stamping Material Stainless Steel, Aluminum Alloy, Brass, Zinc etc Die Standard Dayton Misumi Processing Method Punching and Shearing Mould Technics Forming Die Process Combination Progressive Die Manufacturing Technology Computer Technology Driving Motor Type Permanent Magnet Mold Cavity Technology CNC Milling Milling Speed Normal Speed Parts Detection Method Measurement of Three Axis NC Transport Package Wooden Case Specification SGS, ISO Trademark huihai auto Origin Zhongshan HS Code 8207300090 Production Capacity 500 Sets / YearProduct Description

Our Advantages:1. Competitive price

2. Strict quality control system (ISO9001 system manage)

3. Quick mold making and delivery (4-7weeks)

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Huihai specializes in manufacturing and supplying of various moulds and dies, such as metal stamping dies, plastic injection moulds, motor stator&rotor molds and stamping parts and injection parts since 2005.

Huihai provides various molds & dies to the clients from USA, Spain, Italy, Russia and so on.

"Good quality with cost-effective" is the base of Huihai business. Huihai people keep creating value for customers as our mission.

ISO 9001: 2008 certificated.

Special info.:

Customized design according to customer part design or sample.

Mold base: Standard mould base or customized

Inserts(cavity and core): Cr12mov, SKD11, D2, M2, DC 53, SKH-9, Copper alloy or the material you required.

Standard parts: MISUMI, PUNCH, DAYTON, DANLY (Japan or Europe US)

Part material: SPCC, SPCE, SPCD, DC01, DC04, Stainless steel 304.430.316, Aluminum alloy, and so on

Lead time of first samples: Around 4~7weeks.

FAQs:

Q. What is your standard lead-time?

A. It is difficult to provide a standard lead-time without specific details regarding the particular part, the material gage, the surface requirement or other specific details required. But we control our normal lead-time is from 30 to 60 days.

Q. What is your on-time delivery record?

A. Our on-time delivery records is tracked, monitored, and communicated as we work to meet a 100% on-time delivery goal. Delivery is very important to our customers who need it to meet the hot sale period and it is very important for us to keep the long term relationship between us and our customers. Our on-time delivery record for last several years averages between 98% to 100%, and we make always 100% as our goal.

Q. How do you control your manufacturing processes?

A. Every part we manufacture starts with a complete review of the print, tolerances, customer specific part requirements and customer demands to insure all steps are on foot properly. We offer inspection document including setup sheet, materials we use, testing requirements, package requirements. If you need, we will schedule a kickoff meeting with you that maybe better.

Q. What's your finishing services?

A. Usually we offer polishing, painting, plating, heat treating and TD costing.

Q. What type of quality system you have?

A. We are certificated to SGS factory audit, ISO9001: 2008.

Q. Is small quantity is available?

A. Yes, we can accept the small quantity, even 1 set of stamping dies.

Q. How do you ship the goods?

A. We have the cooperate forwarder, they can ship your goods in short time with the favorable cost to your destination ports. B/L or telex release. Or you can use your shipping agent is available.

High quality steel stamping mould stamping part flow:

1. place the mould order and pay the deposit;

2. our drawing or customers drawing;

3. customers check the design and confirm;

4. production process and the sample;

5. customers check the sample and confirm;

6. receive the balance and arrange the shippment;

7. offer afer sales services.