Aluminum Die Casting Housing Gearbox Power Transmission Aluminum

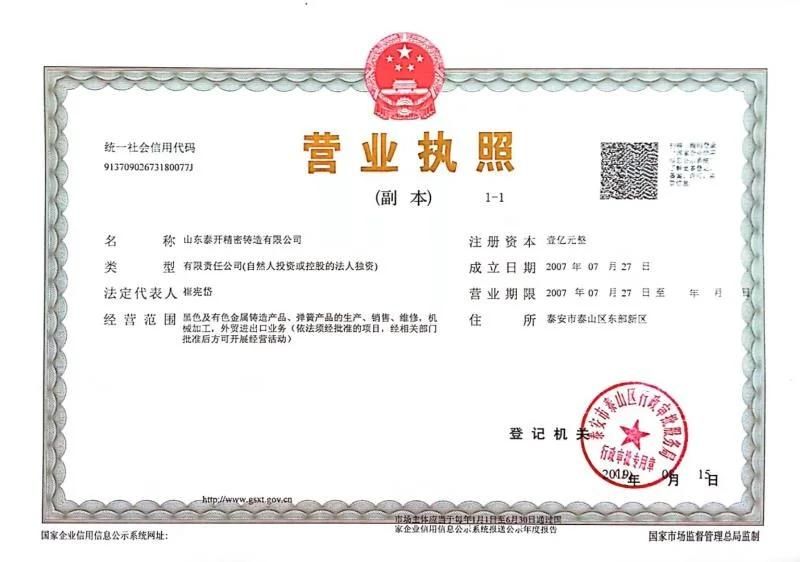

Shandong Taikai Investment Casting Co., Ltd.- Function:Anti-Cold

- Material:Aluminium

- Application:Commodity, Hardware, Household Appliances, Car, Electronic, Home Use

- Type:Ordinary Sand Casting

- Mold Material:Sand Mold

- Certification:RoHS, CE, ISO

Base Info

- Trademark:TK Taikai

- Specification:ZL101A ZL104

- Transport Package:Naked

- Condition:New

- Customized:Non-Customized

- Metal Color:Black Metal

- Warranty:18 Months

- Model NO.:Aluminum body die casting tank cover

- Origin:Shandong Province of China

- HS Code:76109000

Description

Gear Housing Casting

Gear Housing parts Casting

Gear Housing Low pressure Casting

Introduction

For LPDC low-pressure die casting, accurate control of pressure is extremely important for product quality. TK system, with microcomputer control and feedback control, provides unprecedented pressure control, making it ideal for products that have complicated shapes or use cores for mechanical casting parts industry. Our Gear Housing Casting is made with raw material aluminum ZL101 and ZL104(GB), it is lightweight, superior cleanliness, Eco-friendly and all can be customized with different weightness and big size more than 200KG.

Gear Housing Casting suppliers

Gear Housing parts Casting suppliers

Gear Housing parts Casting manufacturers

Casting method:

Low Pressure Aluminum Casting(LPDC); Die Casting; Sand Casting; Gravity Casting; Wax Casting etc.

Advantage:

The advantages of Gear Housing Casting parts are Eco-friendly, lightweight,water-cooled, superior cleanliness, competitive price and after-sales, OEM& ODM.

Classification:

SUV, MPV, Sports Car, Military Car and Passenger car etc.

Material :

ZL101(ZAISi7Mg)/ZL104(ZAISi9Mg)

Application :

Automobile especially eco-friendly new energy vehicle and high-end car, such as Audi, BMW, VOLVO etc.

Heat treatment : T6

T6

Casting tolerance:

CT7

Standard:

according to customers drawing request

Certification:

ISO9001:2015 ISO14001:2015 OHSAS18001:2007 TS16949 etc

Casting process :

400kg to 1000kg low pressure casting; 600kg to 1500kg melting furnace; continuous aluminum alloy heat treatment production line; shell core/sand mixing/shot blasting machine processing etc

Machining process :

Vertical/Horizontal processing ,CNC vertical lathe/ turning processing etc

Inspection process :

X-RAY real-time imaging machine; SF6 gas leakage detector; Aluminum liquid performance tester; German Cai Si metallographic analyzer; CMM etc

Service :

OEM and ODM customized

Shandong Taikai Investment Casting Co., Ltd. is auto parts die casting parts manufacturer and exporter in china, specialized in the research, development and production of customized generator housing die casting parts used in passenger car series .

- Features

- Specification

- Related Products

Shandong Taikai Investment Casting Co., Ltd. is auto parts die casting parts manufacturer and exporter in china, specialized in the research, development and production of customized generator housing die casting parts used in passenger car series .

Introduction

American standard material is applied in producing generator housing die casting parts made by low pressure aluminum casting method(LPDC), of which can produce medium and larger casting parts(200kg and above). The motor housing die casting parts can be customized according to clients' specific requirements.

Generator Housing Casting

Generator Housing Casting suppliers

Generator Housing Casting suppliers manufacturers

Applications

Aluminum castings improve automotive fuel efficiency by contributing to weight saving requirements

Aluminum is used in a broad range of networking and infrastructure equipment in the telecom and computing industries because RF filter boxes and housings require heat dissipation

In handheld devices, aluminum castings provide EMI/RFI shielding, rigidity, and durability with minimal weight

Because of aluminum's excellent electrical performance and shielding properties, even in high-temperature environments, die cast aluminum is ideal for electronic connectors and housings

The company has more than 700 employees, including 120 engineering technology personnel for research and development , and establish professional R&D center. The design and production of product adopt CAD,CAM, SuperWorks, Solidworks, UG,CAE casting simulation etc. mainstream designing analysis software, which could design product structure with scientifically and reasonably.

Hot Tags: generator housing casting, China, manufacturers, suppliers, factory, plant, custom

e urban bus electric motor housing casting made by low pressure die casting(LPDC) craft from Shandong Taikai Investment Co., Ltd, we focus on research, development and production of tailor-made Rail transit casting parts applied in train,subway and high speed rail industry.

Introduction

An innovative Low Pressure Die Casting (LPDC) process is widely used by TK company to produce urban bus electric motor housing casting, the LPDC help us easily to produce medium and larger casting parts(200kg and above). The customized rail transit casting part is made by raw material aluminum ZL101 and ZL104(GB). The advantages of urban bus electric motor housing castings are lightweight,water-cooled, Eco-friendly, high dimensional accuracy, superior cleanliness, competitive price and after-sales, OEM& ODM and so on.

Urban bus electric motor housing casting

bus electric motor housing casting

electric motor housing casting

Casting method:

Low Pressure Aluminum Casting(LPDC); Die Casting; Sand Casting; Gravity Casting; Wax Casting etc.

Advantage:

The advantages of urban bus electric motor housing casting parts are Eco-friendly, lightweight, competitive price and after-sales, OEM& ODM. Continual working under worst condition for long time.

Classification:

SUV, MPV, Sports Car, Military Car and Passenger car etc.

Material :

ZL101(ZAISi7Mg)/ZL104(ZAISi9Mg)

Application :

Automobile especially eco-friendly new energy vehicle and high-end car, such as Audi, BMW, VOLVO etc.

Certification:

ISO9001:2015 ISO14001:2015 OHSAS18001:2007 TS16949 etc

Casting process :

400kg to 1000kg low pressure casting; 600kg to 1500kg melting furnace; continuous aluminum alloy heat treatment production line; shell core/sand mixing/shot blasting machine processing etc

Machining process :

Vertical/Horizontal processing ,CNC vertical lathe/ turning processing etc

Inspection process :

X-RAY real-time imaging machine; SF6 gas leakage detector; Aluminum liquid performance tester; German Cai Si metallographic analyzer; CMM etc

Service :

OEM and ODM customized