China Customized Design ABS Electronic Enclosure Plastic Mold Advantage Plastic Products ...

Dongguan Yixun Industrial Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PP+10GF

- Mould Cavity:Multi Cavity

- Surface Finish Process:Heat Treatment

- Shaping Mode:Injection Mould

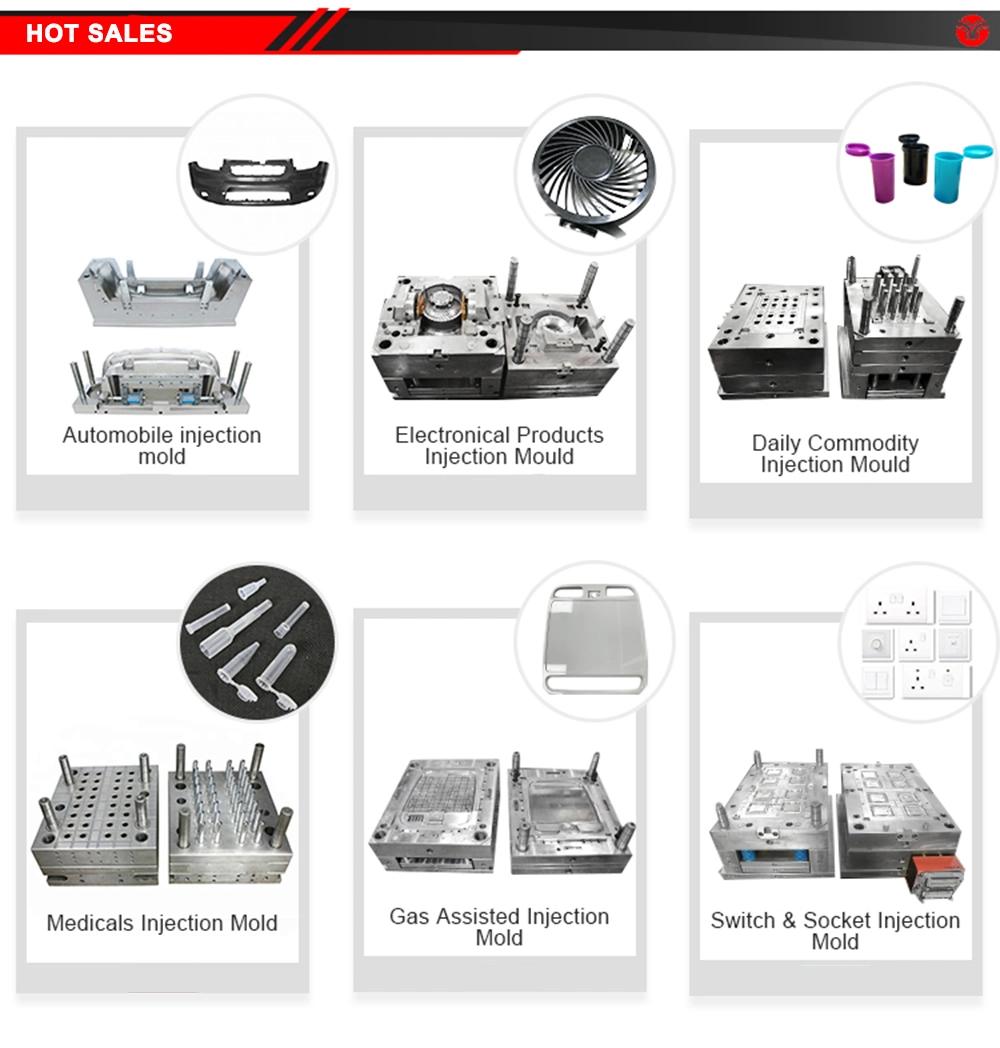

- Application:Car, Household Appliances, Commodity, Electronic, Home Use

Base Info

- Mold Material:Nak80, Steel 20, 1.2738 and So on

- Company Style:Factory

- Size:According Client′s Drawing or Sample

- Delivery Time:Customized

- Dimension Tolerance:ISO02768

- Drawing Format:STP , X-T , Igs , Dwg

- Mold Standard:Lkm , Hasco , Dme , Ftaba

- Type:OEM Custom Socket Injection Mold

- Customized:Customized

- Certification:TS16949, ISO

- Installation:Mobile

- Design Software:Pro-E

- Runner:Hot Runner

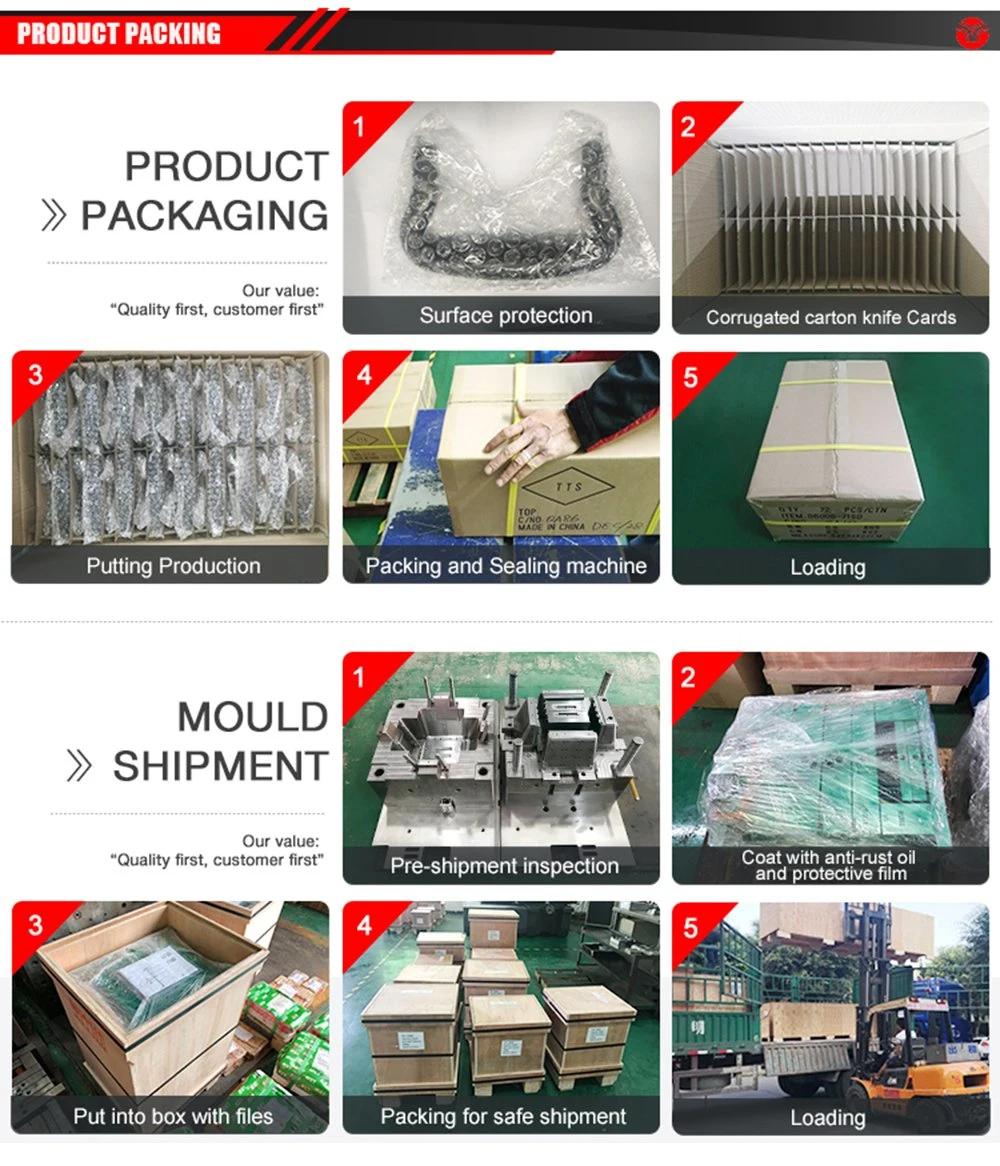

- Transport Package:Plywood Case

- Specification:DME

- Trademark:yixun

- Origin:China

- HS Code:8480710090

- Production Capacity:50 Sets , Month

Description

Mould material

100~300k, Mould Material(Soft Mould):P20,718,2738......

300~500k, Mould Material(Hard Mould):H13,S136,2344......

500~1000k, Mould Material(Hard Mould):2343EFS,2344ESR, 2367ESR,SKD61......

Commercial polishing (General Polishing)

Highly polish (Mirror Polish)

Matte Finish (EDM Treatment)

STP/ STEP, IGS/ IGES, x_t, CAD

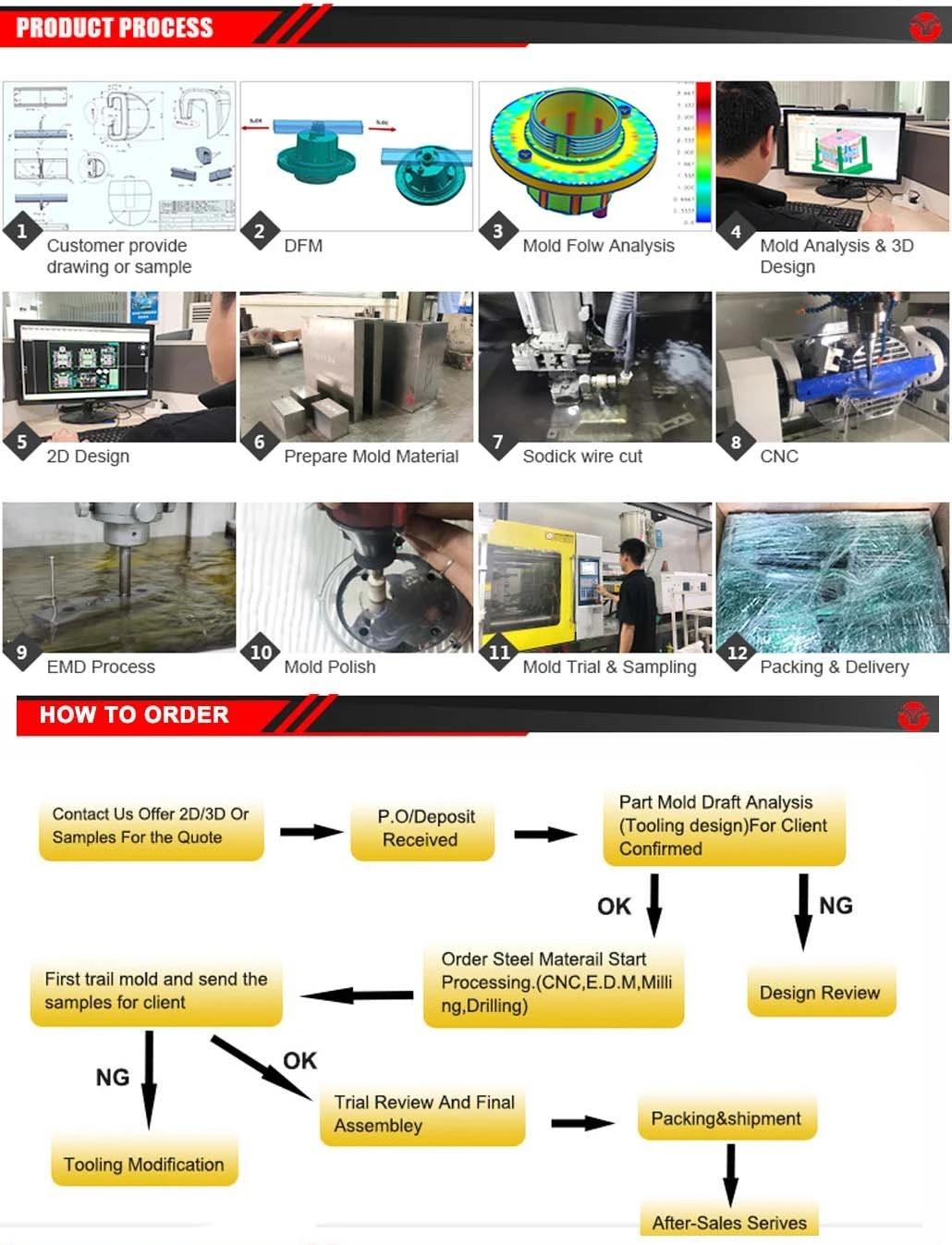

Fast mould design

We can be within 1-3 working days after getting customer's drawings.

Lead time

35 - 45 days after getting the mould design confirmation.

Mould testing

All of the moulds can be well tested before the shipments. Videos testing the moulds are available.

Minimum order

Small orders can be accepted.

Production capacity

45-50 sets/month.

Port

Shanghai

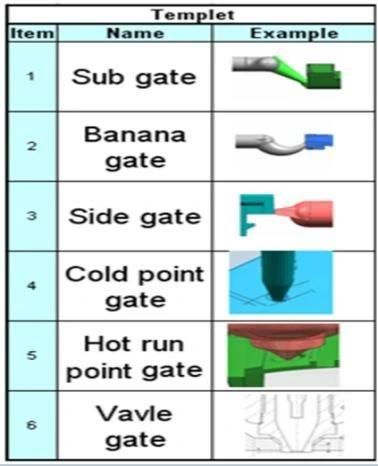

Runner

Payment terms

L/C T/T Western Union MoneyGram.

Mould making service

OEM/ODM service is available.

After-sales service

Life-long gurantee, Comes with free mold parts.

Safe packing

In strong wooden pallets to avoid any damages during long transportation.

Dongguan YIXUN Industrial Co.,Ltd is a high technology company,specializing in many kinds of plastic mold designing,manufacturing and

injecting,mainly covering the enclosure and part of automobile,electrical,printer,commodity,electronic etc.

YiXun has 2 manufacturing facilities, totally 12,000 square meters, 260 employees, 90% of them has experience over 10 years.

YiXun yearly capability is up to 600 sets mold per year, the biggest reach 25 tons.

YiXun adopt the up-to-date design software, such as Auto CAD, UG, Pro/E, Solid Works etc, Mould standards such as DME, HASCO,

FUTABA, LKM and so on.

YiXun has a full set advanced mould manufacturing equipment, 8 sets CNC machines, 15 sets EDM machine, 3 sets middle speed Wire

Cut Machine,

2 sets slow speed Wire Cut Machine, 15 sets Milling Machine, 4 sets lathe machine, 2sets mold die fitting machine,17 sets injection

machine from 35 tons to 818 tons.

Mold FAQ

Q:How about your quality control?

A:We have professional team to control mold quality, since we realize that quality control is the first priority to run business.

Q:What's your lead time?

A:For most mold, 45 to 60 working days ( not including Chinese official holidays ) after deposit received and mold drawings approved.

Q:How long can i get the sample?

A:Depends on your specific items,within 3-7 days is required generally.

Q:What about after service?

A:Spare part which is non-man made damaged will be offered for free within one year, and you can contact us at any time if you need help.