Plastic Blowing Molds for Various Plastic Bottle Production Manufacturer

ZHEJIANG TONVA PLASTICS MACHINE CO., LTD.- Application:Household Appliances, Furniture, Commodity, Home Use, Hardware

- Plastic Material:HDPE

- Mould Cavity:Multi Cavity

- Surface Finish Process:Heat Treatment

- Shaping Mode:Blowing Mould

- Runner:Cold Runner

Base Info

- Specification:40x60x80

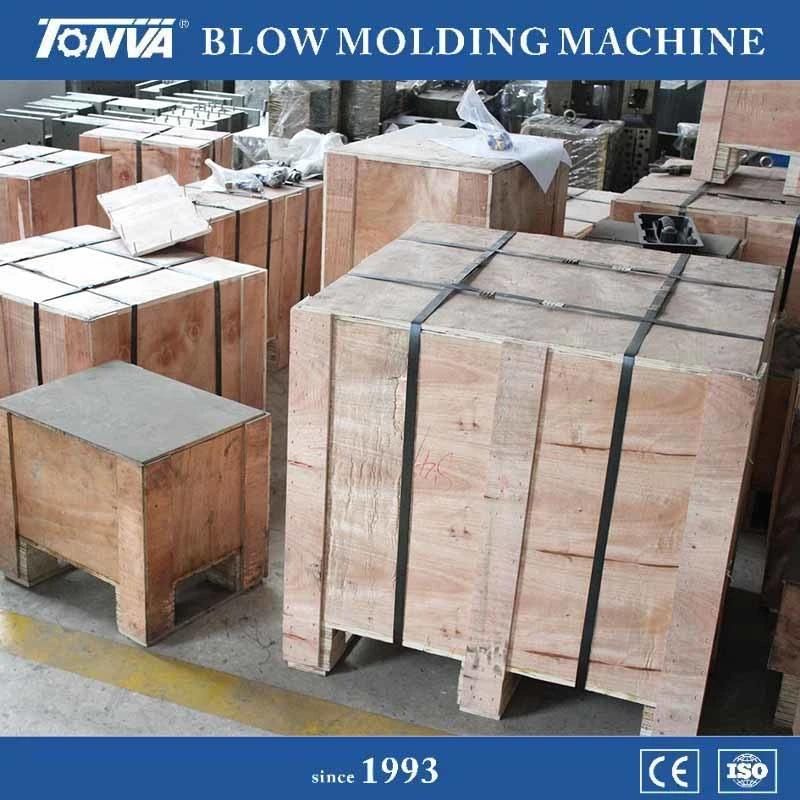

- Transport Package:Wooden Case(Export Standard)

- Warranty:One Year or 2 Million Shots

- Auto Deflashing:Optional

- Mold Cavity No:Customized

- Mold Material:P20

- Mould Type:Blow Mould & Injection Mould

- Customized:Customized

- Certification:CE, ISO

- Design Software:UG

- Model NO.:TVM-000

- Trademark:TONVA

- Origin:China

- HS Code:8480790090

- Production Capacity:1000sets Per Year

Description

Basic Info.

Model NO. TVM-000 Design Software UG Certification CE, ISO Customized Customized Mould Type Blow Mould & Injection Mould Mold Material P20 Mold Cavity No Customized Auto Deflashing Optional Warranty One Year or 2 Million Shots Transport Package Wooden Case(Export Standard) Specification 40x60x80 Trademark TONVA Origin China HS Code 8480790090 Production Capacity 1000sets Per YearProduct Description

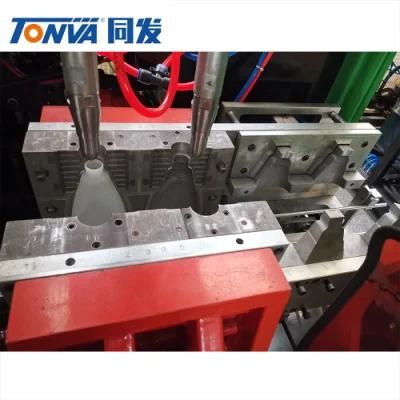

1. TONVA Mould Type:Blow Mould

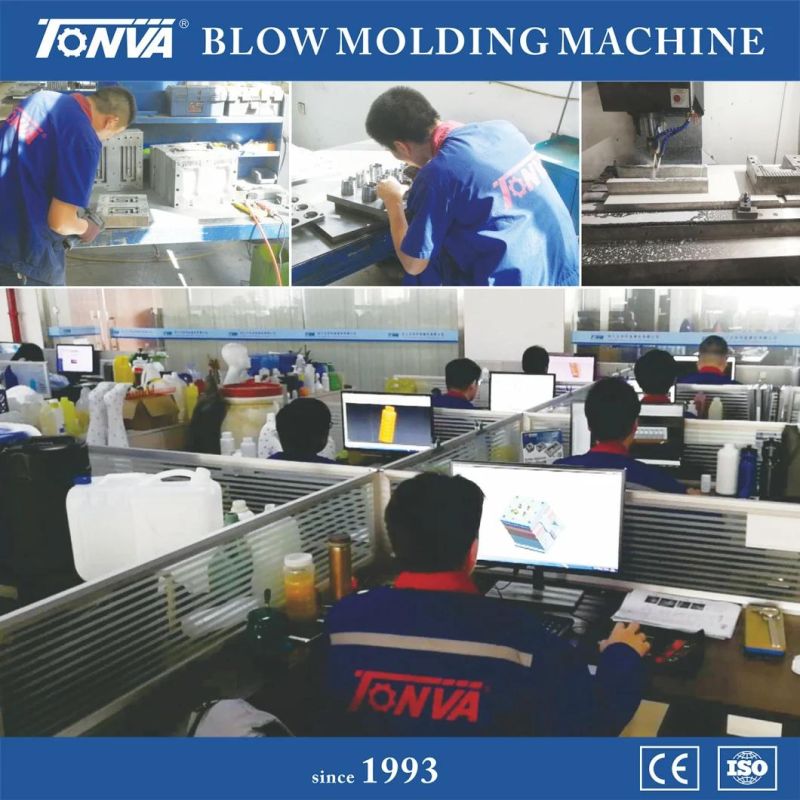

2. TONVA mould produce process

2.1 Product design: Customer send us the product drawing or sample directly; or we draw the product according to customer requirement.

2.2 Mould Design: After the product drawing confirmed by customer, We' ll start to design mould following the mould drawing.

2.3 Mould Making: After the mould drawing confirmed, we start the moulds and the process including: prepare steel, rough cut, finish machining, assembly etc.

2.4 Mould Test: we'll test the mould after mould assembly, send customer samples. We have machine factory by our own. It is easy and quick to test moulds.

2.5 Final Process: The mould start to polish if the samples be accept and make grain, nitridation or chroming if customer requirement

2.6 Mould Packing: We packing mould with wooden case.

3. Our Company

When it comes to innovative and full range of blow molding machines and molds, you need focus on no further than our TONVA machine in China, which established since 1993. TONVA's pioneering technologies, rich experience of our strong R&D team, and good service have allowed us to be one of the leaders of this plastic industrial for over 25years.

Our clients in a wide range of plastic industry sectors, such as: daily using, toy, chemical container, agrochemical, pharmaceuticals, automobile, food, traffic using etc., volume range from 3ml to 5000L, single layer to 6layers, single color to three colors, which are all available on TONVA machine production, clients from more than 80 countries, have to come rely on the knowledge and technologies of a brand which stand for both quality and reliability.