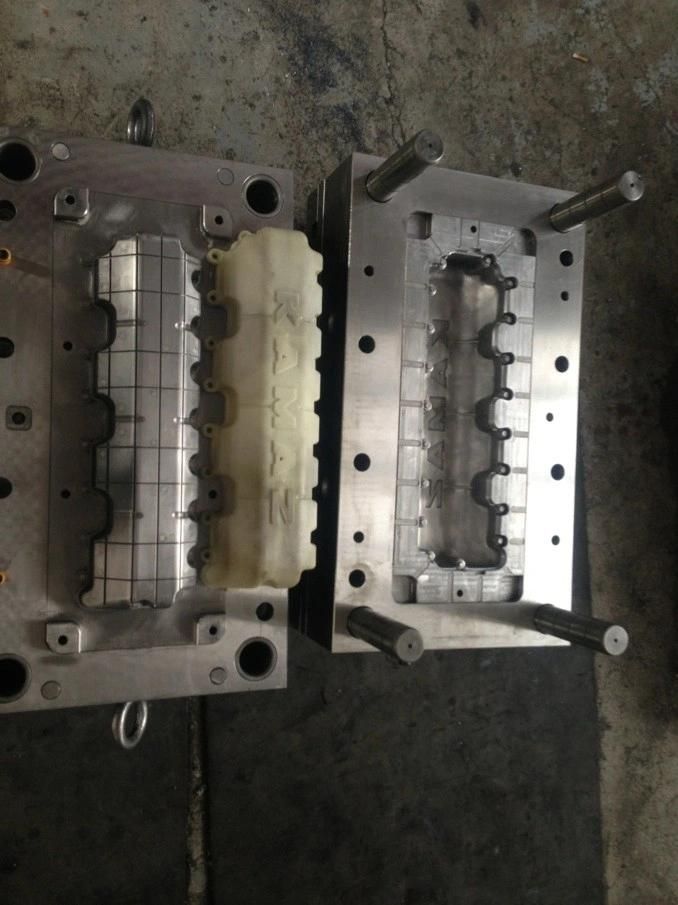

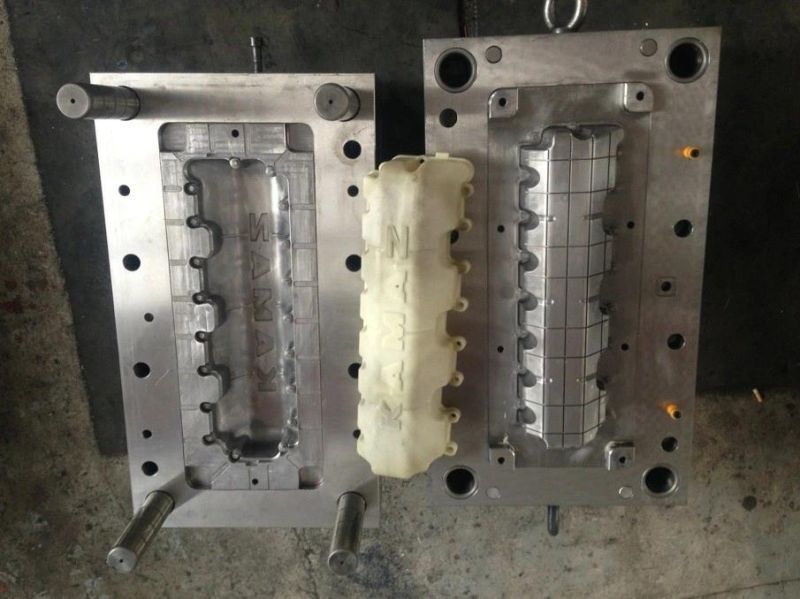

Customized Injection Moulds for Bucket

Yuyao Xianghao Mold Technology Company Limited- Surface Finish Process:Polishing

- Mould Cavity:Multi Cavity

Base Info

- Transport Package:Steel Box

- Plastic Injection Mould/Injection Mold:Plastic Mold,Plastic Injection Mould,

- Customized:Customized

- Standard:DME

- Certification:TS16949

- Installation:Mobile

- Design Software:UG

- Runner:Hot Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use

- Process Combination Type:Compound Die

- Plastic Material:HDPE

- Model NO.:plastic mold for bucket

- Specification:900x860x770mm

- Trademark:injection mold

- Origin:China

- HS Code:8480410010

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. plastic mold for bucket Plastic Material HDPE Process Combination Type Compound Die Application Car, Household Appliances, Furniture, Commodity, Electronic, Home Use Runner Hot Runner Design Software UG Installation Mobile Certification TS16949 Standard DME Customized Customized Plastic Injection Mould/Injection Mold Plastic Mold/Plastic Injection Mould/ Transport Package Steel Box Specification 900x860x770mm Trademark injection mold Origin China HS Code 8480410010 Production Capacity 20 Sets/MonthProduct Description

Our company provides high quality plastic injection mould and competitive mold price,Our Company specializes in professional mold design and professional mold manufacturing

We have extensive expertise in plastic product development,

xianghao is a plastic injection molding manufacturer who is specialized at producing precision parts including automotive and electric plastic parts.

the mold Warranty time of 3 years and mold component warranty free within 3 years

we have a fast turn around fo rmol dmaking , usually 25 days,

Our services include product assembly and packaging.

Mold mould

Mold

Mould

Injection Mold

Specifications

Mold:

1. ISO/TS16949 Certificated

2. HASO. DME. LKM mould standard.

3. Design software: UG. PROE. CAD etc.

4. On-time delivery

1. Mold Material P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc...

2. Runner Cold runner. Hot runner: Yudo/DME/HASCO

3. Certificate ISOTS16949

4. Standard HASCO. DME, LKM

5. Specification drawings PRO/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE.

6. Precision machining CNC, milling machine, drilling machine, numerical lathe, all types of lathe.

7. Surface finish process polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing.

8. Service OEM service available.

9. Lead time 15-25days

10. Advantage Good quality and strict delivery time.

| Name | plastic injection mould |

| Plastic Material | HDPE, PP, PVC, POM, PC, ABS, POM, PMMA, TPU, TPR, K-resin, PPSU^ |

| Engineering Software | CAD, UG, ProE, CAD, Solidworks, Mastercam, Cimatron^ |

| Core/Cavity Steel | 1.2316, 1.2738, 1.2344, , 718, SKD61, NAK80, P20 ^ |

| Mold Base | DME, HASCO, LKM ^ |

| Mold Spare Parts | DME, HASCO, MISUMI, LKM ^standard |

| Cavity No. | Single/multi customized |

| Runner | Hot, Hot to Cold, Cold |

| Hot Runner Brand | Husky, YUDO, Mold Masters, Synventive, Mastip^ |

| Demoulding | Motor, oil cylinder, stripping plate, slides, angel pin, ejector sleeves ^ |

| Mold Life | 500, 000 - 5000, 000 shots |

| Lead Time | 3-8 weeks according to complexity of mold |

| Packaging | Fumigation-free wooden box |