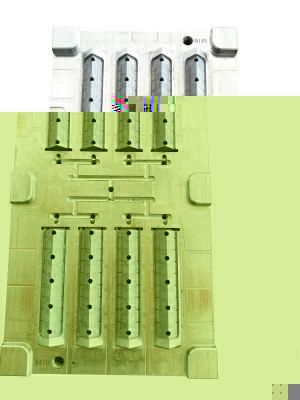

Kids School Things Stationery Plastic Rulers Molded Parts Injection Tooling

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Tech Polish, High Gloss, Texture, Printing

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Steel Treatment:Heat Treatment, Nitriding, Chrome Plating

- Mold Life:500,000 Shots - 2,000,000 Shots

- Ejection System:Stripper Plate, Lifter, Push Bar, Ejection Pin, Et

- Mold Gate:Fan Gate, Sub Gate, Pinpoint Gate, Valve

- Hardness of Steel:46~56HRC

- Core and Cavity Material:DIN2312, 2738, 2344, 718h, S136h, 8407, Nak80, SKD

- Customized:Customized

- Standard:DME

- Certification:CE, ISO

- Installation:Semi Fixed

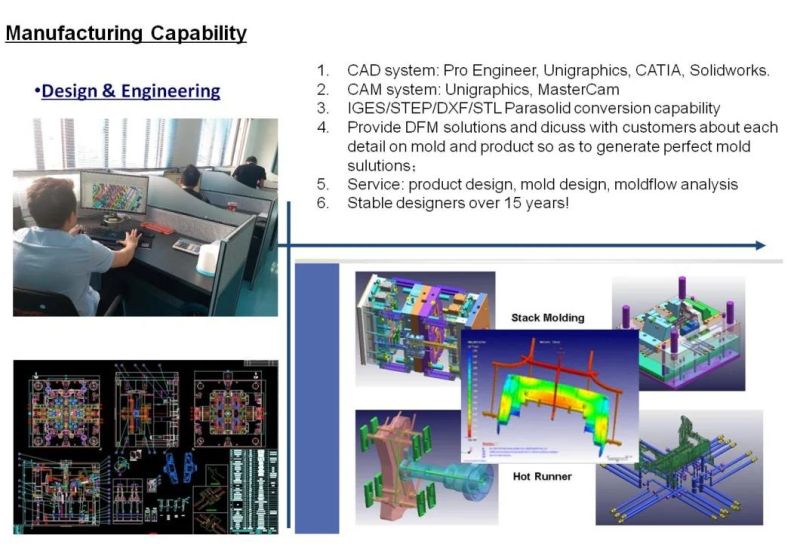

- Design Software:Ug, Autocad, PRO-E

- Runner:Hot Runner

- Model NO.:HW-201202-3

- Mould Precision:+ , - 0.01mm

- Transport Package:Wooden Cases,Air,Sea

- Specification:According to customers′ drawings

- Trademark:OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:300-400 Sets,Year

Description

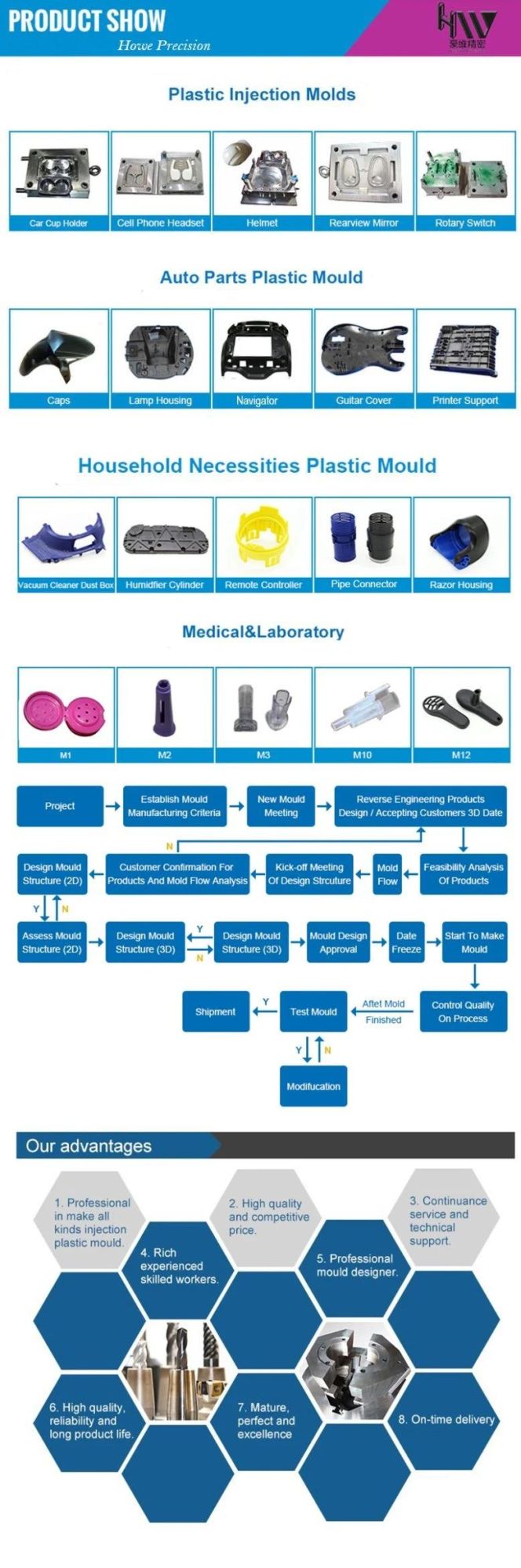

Process of making moulds

| 1.Sample/Drawing | After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis. |

| 2.Negotiation | Material, cavity, price, delivery time, payment term etc. |

| 3.Place Order | when all terms are agreed by both sides, then we will accept an order. |

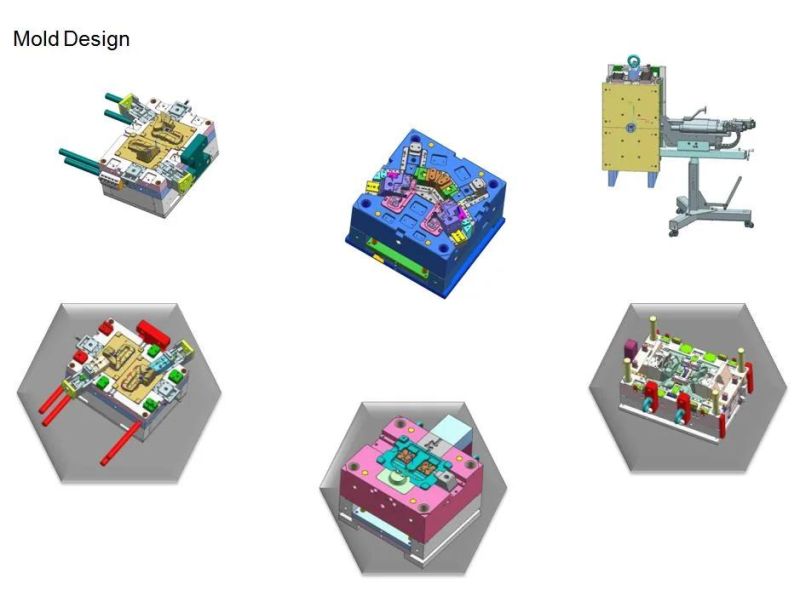

| 4.Mould Design | Our R&D team will design the mould per customer requirements and send drawings for approval. |

| 5.Tooling Mould | Once the mould design is approved will start mould tooling. |

| 6.Mould Process | CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. |

| 7.Sample Confirmation | Send samples for confirmation, if not approved we will adjust the mould structure. |

| 8.Mass Production | After the customer approves the sample, we will arrange mass production. QC will inspect after products finished. |

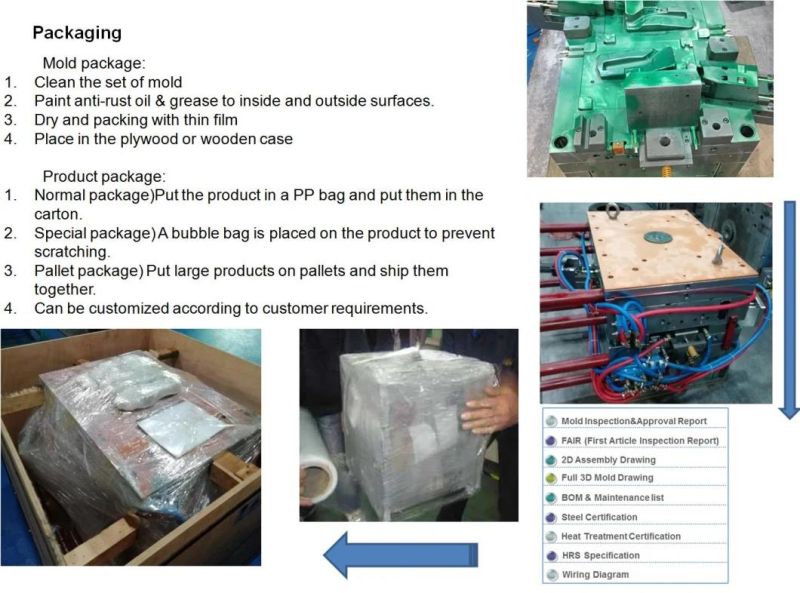

| 9.Package | PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing. |

| 10.Delivery | By sea or by air according to customer requirements. |

| 11.After-sales Service | Ready to help customers solve any possible problems. |

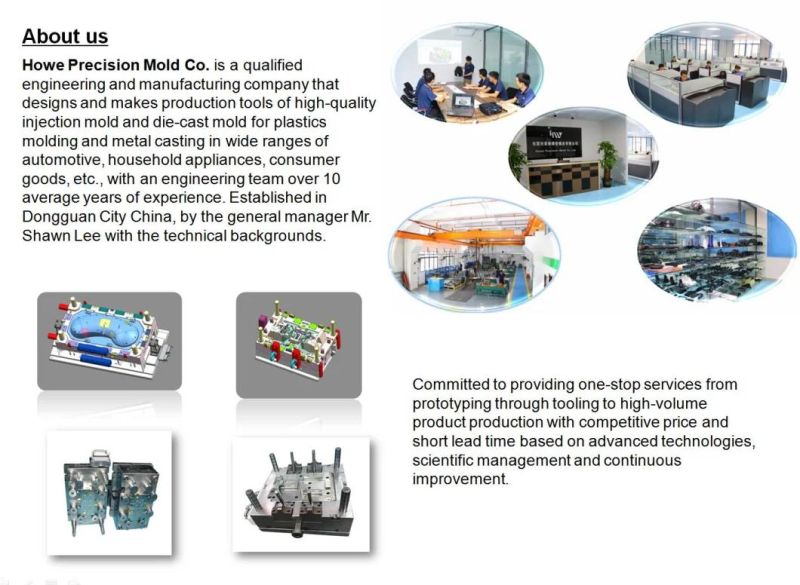

Company profile

Our team

Quality Control

Our workshop

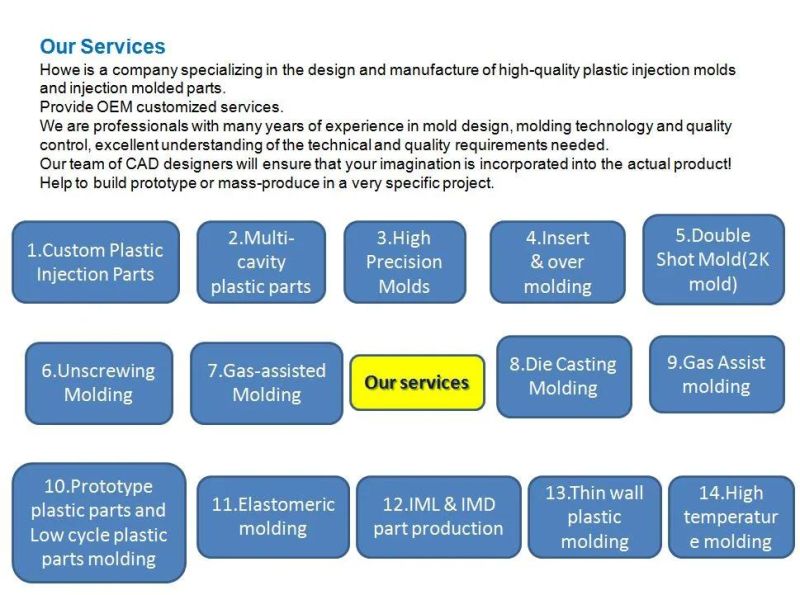

Our Services

Packaging detail

FAQ

Q: Can you accept OEM service?

A: Yes, we are warmly welcome OEM service. Just send your 2D&3D drawing or golden sample with quality demand (such as material, surface treatment, color, and package) to us.

Q: What is the drawing format you needed?

A: Prefer to STP, DXF for 2D&3D drawing, and PDF, AI, CDR, JPG for artwork design.

Q: What is your MOQ?

A: Usually our MOQ is 1000pcs, but we accept lower volume for your trial order.

Q: Can I get samples?

A: Sure, we usually provide a free store sample to you for quality checking. 1~2days can delivery. But there is a little sample fee that would be charged if you request your OEM samples, and it is refundable when your order is up to a certain quantity. 3~5days can delivery.

Q: How much is the freight charge?

A: To save money and time, we suggest to deliver by express for small quantity, and deliver by sea for large quantity. At the same time, we can get a big discount from a shipping company.

Q: Do you have a quality guarantee?

A: Yes. We have a QC department and 100% inspection before shipping, to ensure the CNC parts is NO visual defects, a traceable quality record for the product shipped from us, and if any fault is found, we commit to send a replacement at our cost, or any other more suitable solution depends on discussion with our customers.