Custom Molded Composite Stretch Insulators/Composite Suspension Insulators

Suzhou Kiiwoo Technology Co., Ltd.- Surface Treatment:Polish

- Cavity:Multi-cavity

- Manufacturing Processes:Pressing Forming Mould

- Application:Car, Commodity

- Product Type:Car Mould

- Working Temperature:(-60℃-200℃)

Base Info

- Trademark:custom

- Specification:custom

- Transport Package:PP Bag, Carton

- Customized:Customized

- Warranty:3 Years

- Mould Life:500000-1000000 times

- Certification:UL, FDA

- Model NO.:A025

- Origin:Suzhou, Jiangsu, China

- HS Code:84778000

- Production Capacity:1500unit,Year

Description

Basic Info.

Model NO. A025 Certification UL, FDA Mould Life 500000-1000000 times Warranty 3 Years Customized Customized Transport Package PP Bag, Carton Specification custom Trademark custom Origin Suzhou, Jiangsu, China HS Code 84778000 Production Capacity 1500unit/YearProduct Description

PRODUCT INTRODUCTIONInsulators are widely used in the entire transmission and distribution system. Insulators operate with two basic functions in the overhead transmission line, that is, to support the wire and to prevent the current back to the ground, these two functions must be guaranteed, the insulator should not be failed due to changes of environment and electrical load conditions caused by a variety of mechanical and electrical stress failure, Otherwise the insulator will be useless and it will damage the operating life of entire line. The composite insulators has replaced the glass insulator and ceramic insulators to become the main force of transmission and distribution lines because of its lightweight, high stain resistance and easy maintenance features.

If have any customized needs, please feel free to contact us, we have a professional team of engineers to serve you.

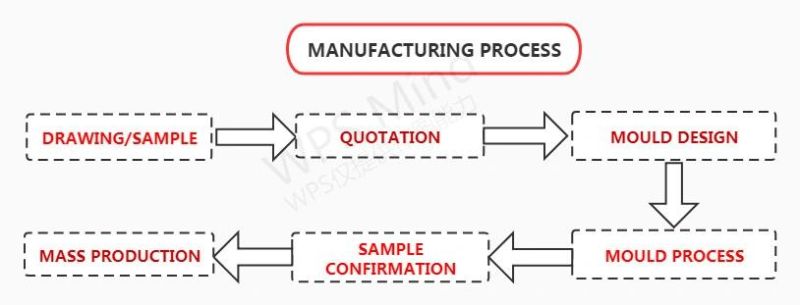

MANUFACTURING PROCESS

'SUZHOU KIIWOO' THCHNOLOGY CO. LTD. manufacture customized products based on samples, drawings or specifications given by the customer 'KIIWOO' offers all kinds of rubber and silicone tools .Customers can provide dr awing or samples to apply a good solution from us .Including rubber automobile part ,rubber orings ,insulators ,electric silicone parts .Her e for some tools we have did for customer befor e For your r efer ence . We have all equipment of injection molding machine ,vacuum pr ess machine ,compr ession machine for tools testing ,and series of inspection machine for product size inspection. Each tool befor e shipment we will do testing and shar e customer videos and samples for Checking .Once 100% agr ee ,then ship out .

SAMPLE ROOM

Customers supply drawing. We make mould and samples. After testing by customers, we make bulk products.

TEST MACHINES

We can make hardness testing, compression deformation rate testing, tensile strength testing, and other testing.

SEND INQUIRY NOW AND GET PRICE SOON.