Custom Silicone Rubber Compression Mould for Rubber Injection

Suzhou Kiiwoo Technology Co., Ltd.- Cavity:Multi-cavity

- Manufacturing Processes:Pressing Forming Mould

- Application:Home Use, Household Appliances, Car, Commodity

- Product Type:Household Goods

- Surface Treatment:Polish

- Working Temperature:(-40℃-300℃)

Base Info

- Trademark:custom

- Specification:custom

- Transport Package:PP Bag, Carton

- Customized:Customized

- Warranty:3 Years

- Mould Life:>1000000 times

- Certification:UL, FDA

- Model NO.:A009

- Origin:Suzhou, Jiangsu, China

- HS Code:84778000

- Production Capacity:50000 Moulds Each Year

Description

Basic Info.

Model NO. A009 Certification UL, FDA Mould Life >1000000 times Warranty 3 Years Customized Customized Transport Package PP Bag, Carton Specification custom Trademark custom Origin Suzhou, Jiangsu, China HS Code 84778000 Production Capacity 50000 Moulds Each YearProduct Description

'

'SUZHOU KIIWOO' THCHNOLOGY CO. LTD. manufacture customized products based on samples, drawings or specifications given by the customer 'KIIWOO' offers all kinds of rubber and silicone tools .Customers can provide dr awing or samples to apply a good solution from us .Including rubber automobile part ,rubber orings ,insulators ,electric silicone parts .Her e for some tools we have did for customer befor e For your r efer ence . We have all equipment of injection molding machine ,vacuum pr ess machine ,compr ession machine for tools testing ,and series of inspection machine for product size inspection. Each tool befor e shipment we will do testing and shar e customer videos and samples for Checking .Once 100% agr ee ,then ship out.

1. Mould Material

NAK80, S136, 2316, 2738, H13, 5CrNiMo,718H, P20, 40Cr, 60#, 45#, etc.

1). Product Material: Silicone rubber

2). Cavity No. Single or multi

System Of Runner Hot runner, Cold runner, Pin-point gate, Submarine gate, etc.

3). Ejector Type: Ejector pin, Air gate, Ejector plate, Hydro-cylinder, etc.

4). Term Of Mould Production: 30days- 55days

5). Guaranteed Number Of Cycles: 300,000-3,000,000 closing

6). Mould Design Software: Ug,Proe, Solidworks AotoCAD, Moldflow, ect.

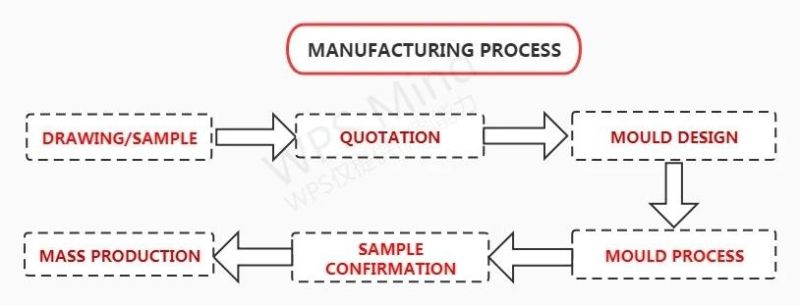

2. Production Process

1). Product Design

Customer send us the product drawing directly or we draw the product according to the sample,then we send customer the product drawing to confirm

2). Mould Design

We'll start to design mould after the product drawing confirmed,then send customer the mould drawing to confirm

3). Mould Making

The mould start to make after the mould drawing confirmed,the process include prepare steel,rough cut,finish machining,assembly etc

4). Mould Test

We'll test the mould after mould assembly,then we'll send customer samples and video of mould test to confirm

5). Final Process

The mould start to polish if the sample is ok,and make grain,nitridation or chroming if customer required

6). Mould Test

We'll test the mould again after polishing,then send customer the final sample and video of mould test to confirm

7). Mould Packing

The mould stard to pack with wooden case after the final sample confirmed,then the mould will be sent to port and waiting for shipping

'SUZHOU KIIWOO' THCHNOLOGY CO. LTD. manufacture customized products based on samples, drawings or specifications given by the customer 'KIIWOO' offers all kinds of rubber and silicone tools .Customers can provide dr awing or samples to apply a good solution from us .Including rubber automobile part ,rubber orings ,insulators ,electric silicone parts .Her e for some tools we have did for customer befor e For your r efer ence . We have all equipment of injection molding machine ,vacuum pr ess machine ,compr ession machine for tools testing ,and series of inspection machine for product size inspection. Each tool befor e shipment we will do testing and shar e customer videos and samples for Checking .Once 100% agr ee ,then ship out .

'SUZHOU KIIWOO' THCHNOLOGY CO. LTD. manufacture customized products based on samples, drawings or specifications given by the customer 'KIIWOO' offers all kinds of rubber and silicone tools .Customers can provide dr awing or samples to apply a good solution from us .Including rubber automobile part ,rubber orings ,insulators ,electric silicone parts .Her e for some tools we have did for customer befor e For your r efer ence . We have all equipment of injection molding machine ,vacuum pr ess machine ,compr ession machine for tools testing ,and series of inspection machine for product size inspection. Each tool befor e shipment we will do testing and shar e customer videos and samples for Checking .Once 100% agr ee ,then ship out .SAMPLE ROOM

Customers supply drawing. We make mould and samples. After testing by customers, we make bulk products.

TEST MACHINES

We can make hardness testing, compression deformation rate testing, tensile strength testing, and other testing.

WHAT WE MAKE

1.RUBBER SEALS

NBR seal ring, low cost, the most widely used seal ring, suitable for gasoline,petroleum, glycol and other media.

Natural rubber sealing ring, with good elasticity and pull resistance.

Butyl rubber sealing ring has good air tightness.

EPDM EPDM rubber seal ring has good ozone resistance and chemical resistance.

It can be used in high temperature water environment, such as water heater, food industry and automobile cleaning equipment.

2. RUBBER PADS

Rubber gasket is widely used in automobile, electronics, chemical industry, antistatic, flame retardant, food, mechanical equipment and other industries. It can play the role of gasket, Dao seal, buffer and so on.

NBR, SBR, Cr, EPDM... Rubber gasket has oil resistance, acid and alkali resistance, cold and heat resistance, aging resistance and other properties, can be directly cut into various shapes of sealing gasket, widely used in medicine, electronics, chemical industry, antistatic, flame retardant, food and other industries.

3.RUBBER AUTO PARTS

Rubber is used in many parts of the car, accounting for 3.5 to 8 percent of the vehicle weight. It is the second largest application material after steel.

The commonly used parts in automobile are tire, sealing strip and sealant, pipeline, transmission, shock absorption, automobile wiper, brake gasket, cylinder head gasket used to seal engine and other high temperature parts, air spring ring (used for shock absorption), sealing ring, tooth shaped cutting belt, automobile synchronous belt, automobile multi wedge belt, automobile engine mounting rubber pad, shock absorber rubber, anti-collision and shock-absorbing rubber, dust cover, fuel tank cover, filter rubber, clip cloth (diaphragm), EFI pump seal ring, Frame seal, door seal, etc.

4. SPECIAL RUBBER PARTS

Rubber profiled parts are outstanding sealing rubber parts in the 21st century

Dust cover is a kind of rubber shaped parts, which is widely used in industry, electronics, architecture, aerospace and machinery.

In general, rubber profiled parts are new products improved on the basis of other seals. It has the characteristics of wear resistance, corrosion resistance, high temperature resistance and good sealing performance, and its great advantage is good sealing. It is used in various factories, dust workshops and places with strong corrosivity.

SEND INQUIRY NOW AND GET PRICE SOON.

| 1 | Mould base material | PVC, ABS, EPDM, NR, NBR, SBR, IIR, CR, SILICONE, VITON |

| 2 | Mould core material | 718H, S136H, NAK80 , P20, etc |

| 3 | Plastic molded parts material | ABS, ABS+PC, PC, PP, PVC, |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Gate | Pin-point gate, Edge gate |

| 7 | Finish | Semi-Matt, Polish |

| 8 | Design software | Pro-E, IGES, UG, CAD CAXA, ect |

| 9 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 10 | Arrangement type | I-section, Straight body mould |

| 11 | Second Processing | Silk-scree Printing, Plating, Painting |

| 12 | Package | Wooden case for mould, carton box for Plastic injection products |

| 13 | Delivery time | 30-40 days for mould and samples. 7days for mass production of Plastic injection molding inc . |

| 14 | Trade Term | Ex-works, FOB Xiamen, CIF |

| 15 | Payment Term | Mould: 50% paid by T/T in advance, balance 50% paid after confirm samples Mass production: 50% paid by T/T in advance, balance 50% paid before loading. |