High Pressure Grinding Roll Tungsten Carbide Stud Pin

SEED TECHNOLOGlES CORP., LTD.- Process Combination:Per Customer Requirement

- Technics:Per Customer Requirement

- Processing Method:Per Customer Requirement

- Material:Per Customer Requirement

- Application:Per Customer Requirement

- Manufacturing Technology:Per Customer Requirement

Base Info

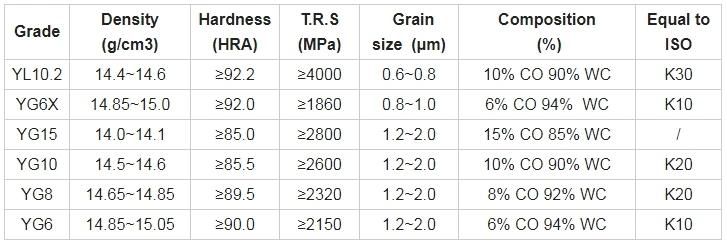

- Cobalt Percentage:From 3% to 30% Based on Different Grades

- Grain Sizes Selection:Ultra Fine, Fine, Medium, Coarse

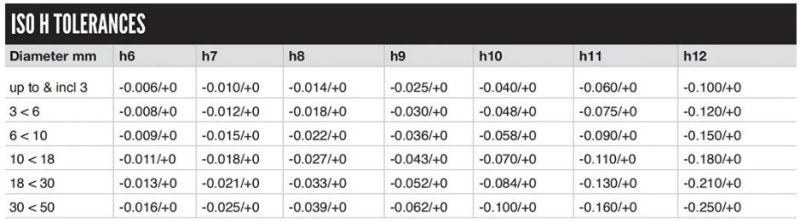

- Surface Finishing:H6 Tolerance

- Length:50~500mm

- Hardness:>91.5 Hra

- Model No.:Yl10.2 Carbide Rod, Tungsten Carbide Drill Rods

- Grade:Yg10X, Yl10.2, Yg6X

- Advantage:High Rigidity & Durable

- Service:Customize ODM OEM

- Features:Wear-Resisting Long Life

- Parts Detection Method:Per Customer Requirement

- Milling Speed:Per Customer Requirement

- Mold Cavity Technology:Per Customer Requirement

- Driving Motor Type:Per Customer Requirement

- Wc+Co Powder:100% Virgin Material

- Transport Package:Standard Package , Customize Packing

- Specification:Dia. 0.5~50mm, Length 10-500 mm

- Trademark:Aseeder

- Origin:China

- HS Code:84819010

- Production Capacity:60 Tons Per Month

Description

Basic Info.

Driving Motor Type Per Customer Requirement Mold Cavity Technology Per Customer Requirement Milling Speed Per Customer Requirement Parts Detection Method Per Customer Requirement Features Wear-Resisting Long Life Service Customize ODM OEM Advantage High Rigidity & Durable Grade Yg10X, Yl10.2, Yg6X Model No. Yl10.2 Carbide Rod, Tungsten Carbide Drill Rods Hardness >91.5 Hra Length 50~500mm Surface Finishing H6 Tolerance Grain Sizes Selection Ultra Fine, Fine, Medium, Coarse Cobalt Percentage From 3% to 30% Based on Different Grades Wc+Co Powder 100% Virgin Material Transport Package Standard Package / Customize Packing Specification Dia. 0.5~50mm, Length 10-500 mm Trademark Aseeder Origin China HS Code 84819010 Production Capacity 60 Tons Per MonthProduct Description

SEED is the leading manufacturer and exporter of tungsten carbide components, Nozzles radial bearings, as well as provide machining service and hardfacing processes based in China, with a branch office set up in Houston dedicated for North American's market in sales and customer support, we are able to manufacturing all kinds of tungsten carbide parts and Alloy wear parts based on your drawing and material specification requirement for difference industry application, welcome to contact us for details.

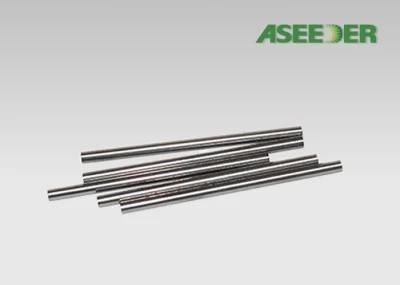

Top Quality Solid Carbide Rod Grinding Solid Carbide Endmills, Drills

Tungsten Carbide Rods Features:

- High stability, long lifespan circle.

- Customized as your requirements.

- Approved factory for oil and natural gas industry TOP5 customers.

- With ASP9100 certificate , API certificate, ISO9001:2015

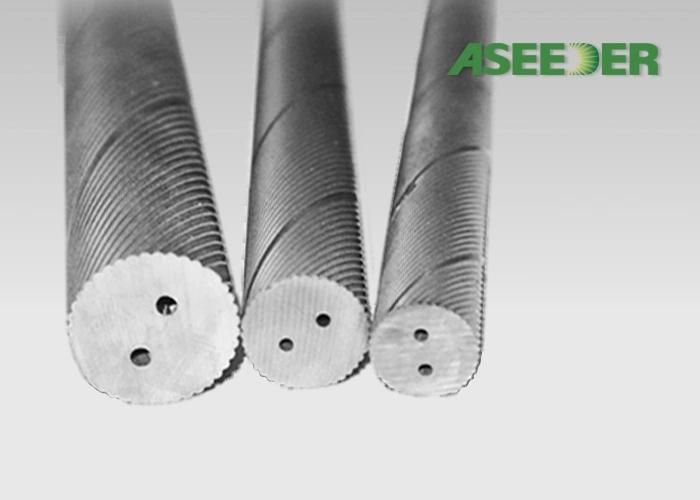

- With a Special Thread Processing Workshop

Aseeder produce various grade of solid tungsten carbide rods, such as YG6 YG12 YG10 YG15 YG20. Each grade has different Chemical composition and physical properties for different application. Besides, they can be used for making of cemented carbide stamping head,core bar & perforation tools.

Size of Aseeder tungsten carbide rods in grade yg6 & yg8: Diameter from 1.0mm to 30mm , length between 10-400 mm(standard length is 330 mm).

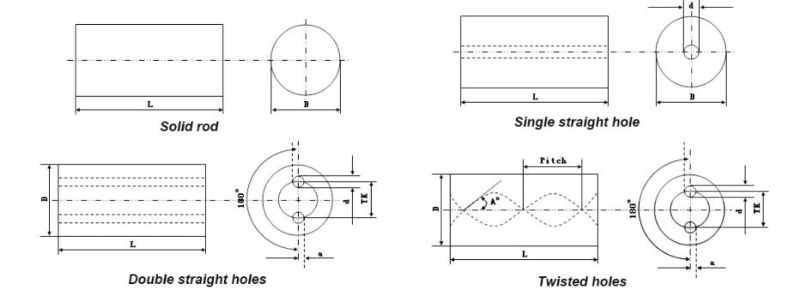

Main types of the tungsten carbide rods.

Aseeder also can produce the customized carbide rods, not only the sizes & shape, but also the grades based on your using purpose. If you need more specification of the tungsten carbide rod, please kindly contact us.

Tolerance standard for Grinding.

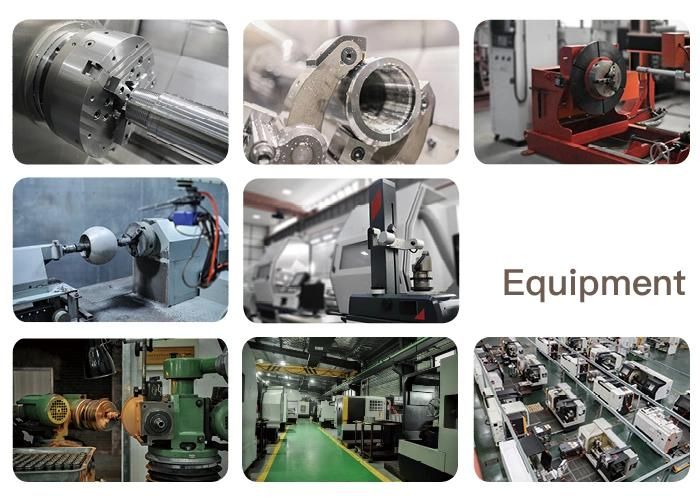

Major Product Lines

· Wear resistant carbide components via powder metallurgy technique

· Hardfacing (oxy-acetylene spray, PTA, HVOF, etc.) and surface enhancement (phosphating, boronizing, etc.)

· High-precision machining of metals (S.Steel, carbon steel, Inconel 718, etc.)

· Additive manufacture