Customized Size Tooling Auto Parts Plastic Injection Mold

PowerfulSky Mould Co., Ltd.- Plastic Material:POM

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:3 Years

- Process Combination Type:Single-Process Mode

Base Info

- Specification:58x48x36cm

- Transport Package:Wood or Customized

- After-sales Service:3 Years

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Application:Car, Hardware

- Trademark:PSM

- Origin:China

- HS Code:3901100001

- Production Capacity:600set,Years

Description

Mould DescriptionMould Size(L*W*H MM) 980*860*450 Mould Gross Weight(KGS) 965 Mould Life Time(Shots) 1,000,000 Mould Manufacturing Cycle 35 days Surface Finish Polishing Runner Description Hot runner Ejection System Eject blade Cycle Time(Second) 55s Injection Gate Type Side gate

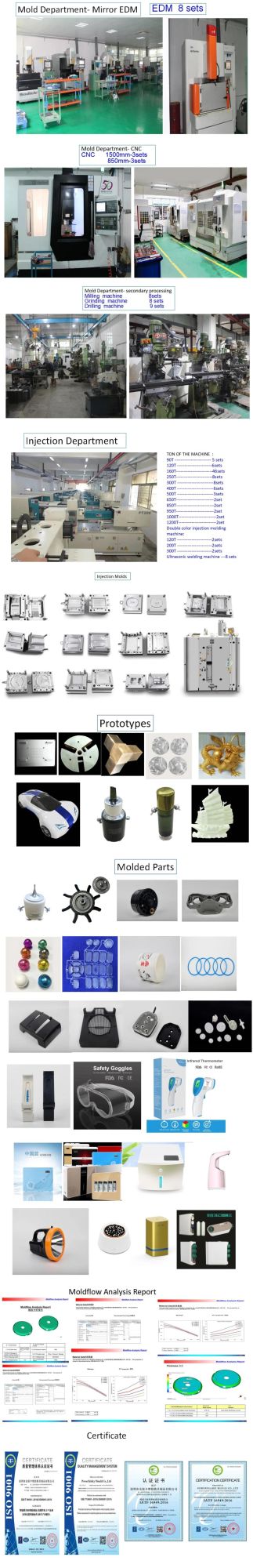

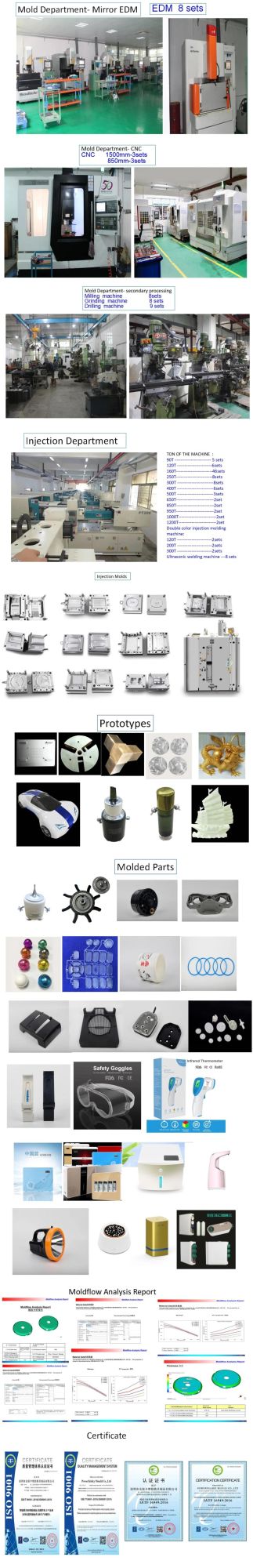

One Stop Service capability: Concept Ideas, Plastic parts design, Rapid prototype, Injection mold tooling, mass production, High quality plastic injection mould, Silicone Rubber compression mould, Aluminium Zinc Magnesium Alloy die casting mould and product assembly.

We are specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high glossy polished molds, interchangeable inserts molds, Inserting moulds, 2shots Overmold, hot runner molds, and pilot trial molds for small series production etc.

We can supply products to customer base from various industries field as: LED Lighting, Water Treatment, Automotive, Medical Products, Diving,Home Hardware , Netcom Products, Office Products(Computer accessories), Housewares Consumer Products, Cosmetic Personal Care Products, Lawn and Garden Tools, Power Tool etc

PowerfulSky provides products and services to our clients all over the world, includde: France, Germany, U.K, Russia, U.S.A., Australia etc.

From our state-of-the-art factory in Shen Zhen,China,Powerfulsky Mould offers the latest in precision engineered technology,with a wide range of services for our customers,including:

From our state-of-the-art factory in Shen Zhen,China,Powerfulsky Mould offers the latest in precision engineered technology,with a wide range of services for our customers,including:

·Injection Molding Prototype Design

·Rapid Prototyping

·Mold Tool Design

·Tool Making

·Injection Molding

·Assembly- Secondary Processing

·Ultrasonic Welding

·Painting

·Printing

We work closely with our customers at every stage of the process,from initial Computer Aided Design and mould tool design through to manufacture,using high quality injection mouldings to deliver an integrated service tailored to their needs.

We are sure that you will find all the information you need about the wide range of precision injection moulding services we offer,however please feel free to contact us for further details.

| Mould Type | Plastic Injection Mold |

| Mould Material | P20/718/738/NAK80/S136 |

| Mould Base | HASCO,DME,MISUMI,JIS,LKM etc |

| Mould Runner | Cold Runner/ Hot Runner |

| Mould Gate | Slide Gate/Sub Gate/Pin- point Gate |

| Cavity | Single /Multi Cavity |

| Designing Software | UG/PROE/CAD/SOLIDWORKS |

| Moulding equipment | CNC,Wire Cutting,Milling Machine,EDM |

| Raw-material | ABS,PP,PC,PA6,PA66,PVC,POM,PMMA,PS etc |

| Package way | Wooden pallet, carton |

| OEM/ODM | Welcome and please offer 2D/3D file or sample |

| Lead time | About 20 days |

One Stop Service capability: Concept Ideas, Plastic parts design, Rapid prototype, Injection mold tooling, mass production, High quality plastic injection mould, Silicone Rubber compression mould, Aluminium Zinc Magnesium Alloy die casting mould and product assembly.

We are specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high glossy polished molds, interchangeable inserts molds, Inserting moulds, 2shots Overmold, hot runner molds, and pilot trial molds for small series production etc.

We can supply products to customer base from various industries field as: LED Lighting, Water Treatment, Automotive, Medical Products, Diving,Home Hardware , Netcom Products, Office Products(Computer accessories), Housewares Consumer Products, Cosmetic Personal Care Products, Lawn and Garden Tools, Power Tool etc

PowerfulSky provides products and services to our clients all over the world, includde: France, Germany, U.K, Russia, U.S.A., Australia etc.

From our state-of-the-art factory in Shen Zhen,China,Powerfulsky Mould offers the latest in precision engineered technology,with a wide range of services for our customers,including:

From our state-of-the-art factory in Shen Zhen,China,Powerfulsky Mould offers the latest in precision engineered technology,with a wide range of services for our customers,including:·Injection Molding Prototype Design

·Rapid Prototyping

·Mold Tool Design

·Tool Making

·Injection Molding

·Assembly- Secondary Processing

·Ultrasonic Welding

·Painting

·Printing

We work closely with our customers at every stage of the process,from initial Computer Aided Design and mould tool design through to manufacture,using high quality injection mouldings to deliver an integrated service tailored to their needs.

We are sure that you will find all the information you need about the wide range of precision injection moulding services we offer,however please feel free to contact us for further details.