Moulding Plastic Injection Mold for Earphones / Headset Cover

Dongguan Howe Precision Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Glossy or Mirror Polished, Textured

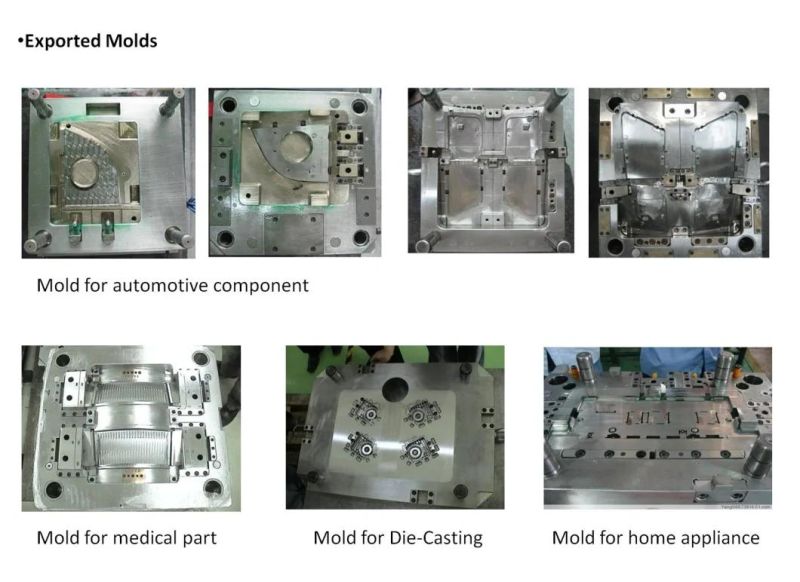

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Cycle Time:10-300S

- Mould Life:300,000-1,000,000 Shots

- Mould Base:Lkm, Hasco, Dme or Upon Customer′s Requirement

- Ejection System:Stripper Plate, Lifter, Push Bar, Ejection Pin

- Gate Type:Fan Gate, Sub Gate, Pinpoint Gate, Valve

- Hardness of Steel:46~56HRC

- Steel Treatment:Heat Treatment, Nitriding, Chrome Plating

- Core and Cavity Steel:DIN2312, 2738, 2344, 718h, S136h, 8407, Nak80, SKD

- Customized:Customized

- Certification:CE, ISO

- Standard:HASCO

- Installation:Semi Fixed

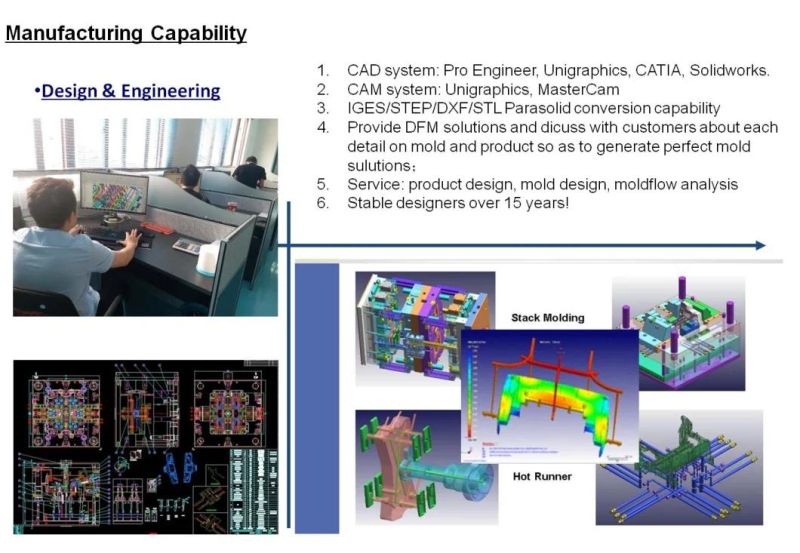

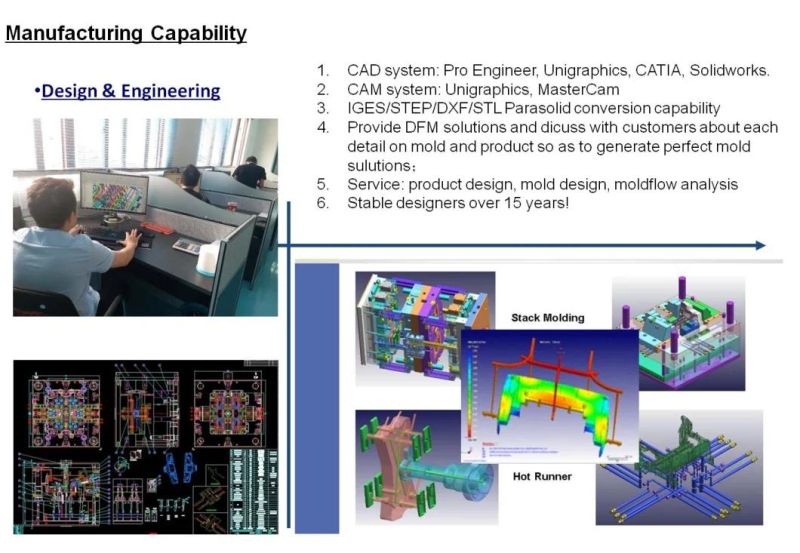

- Design Software:Ug, Autocad

- Runner:Hot Runner

- Model NO.:HW-201117-6

- Transport Package:PE Film for Plastic Parts, Wooden Case for Moulds

- Specification:According to customers′ drawings

- Trademark:HOWE,OEM

- Origin:Dongguan, China

- HS Code:8480719090

- Production Capacity:1, 000, 000PCS,Month

Description

Mould informationInjection mold standard HASCO,DME,MISUMI,China lKM Standard. Please provide 2D, 3D, samples, or the size of the multi-angle pictures. Mould material 45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc. Product material ABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDPE etc. Cavity Single-cavity, Multi-cavity, or by request. Runner system Cold runner or Hot runner. Mould precision ±0.01mm. Mould Life 50-100 million shots. Software CAD, PRO-E, UG, etc. Design Time 1-3 days (normal circumstances). Main technology Milling, grinding, CNC, EDM, wire cutting, carving, lathes, etc.

Mold making process

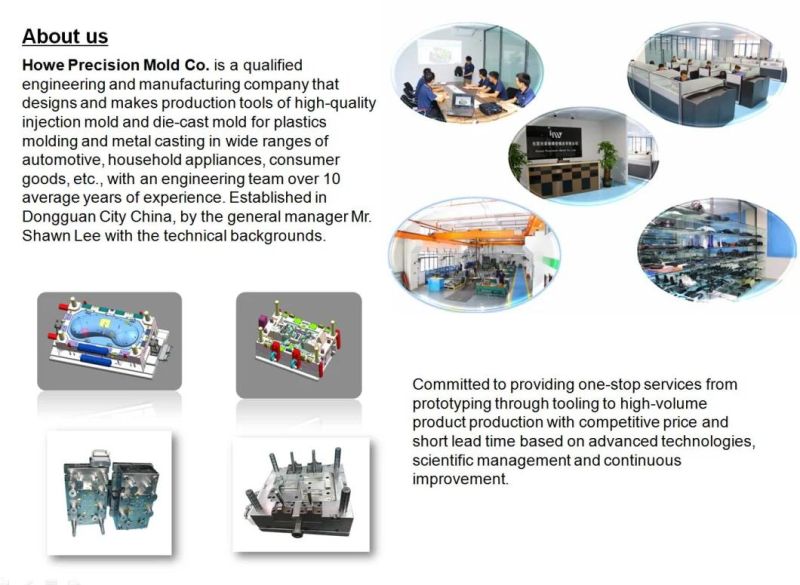

Company profile

Our team

Quality control

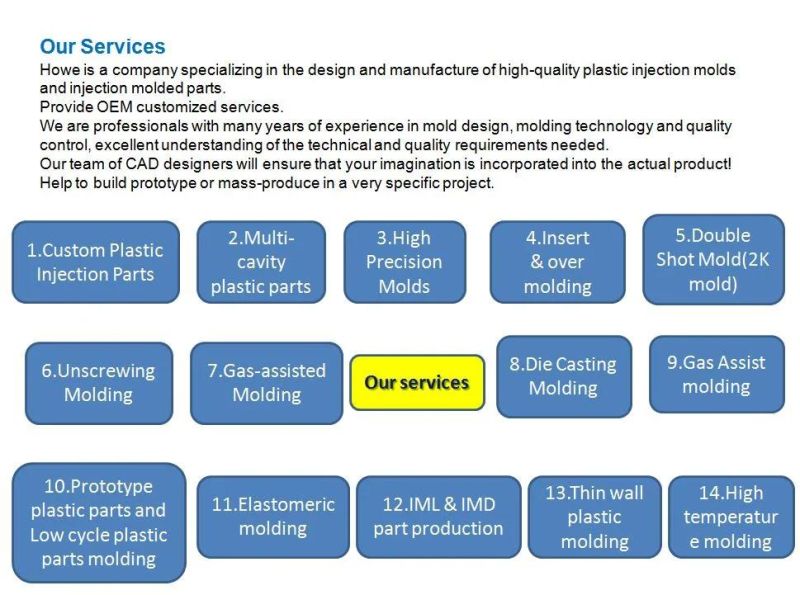

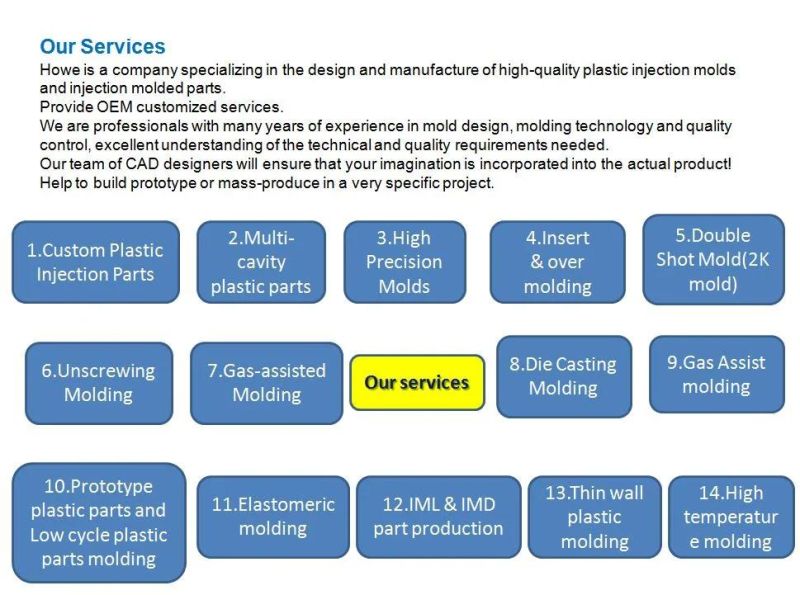

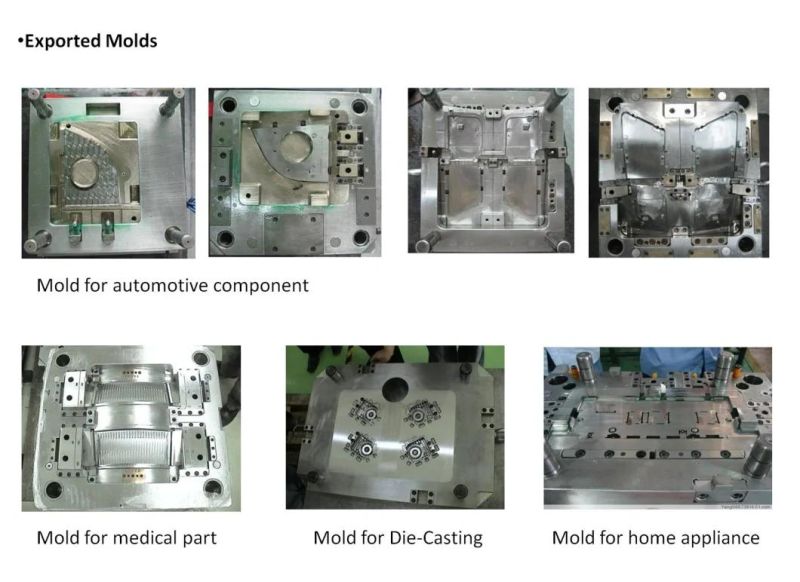

Our services

Our workshop

Packaging detail

Customer Visit

FAQ :

Q1: What kind of molds do you make?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make rubber molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide a steel certificate or hardness certificate to prove.

Q5: Can you make the texture/text/heat_treatment /nitriding for the injection mold plastic?

A5: Yes, As a plastic mold factory, we have long term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by clients.

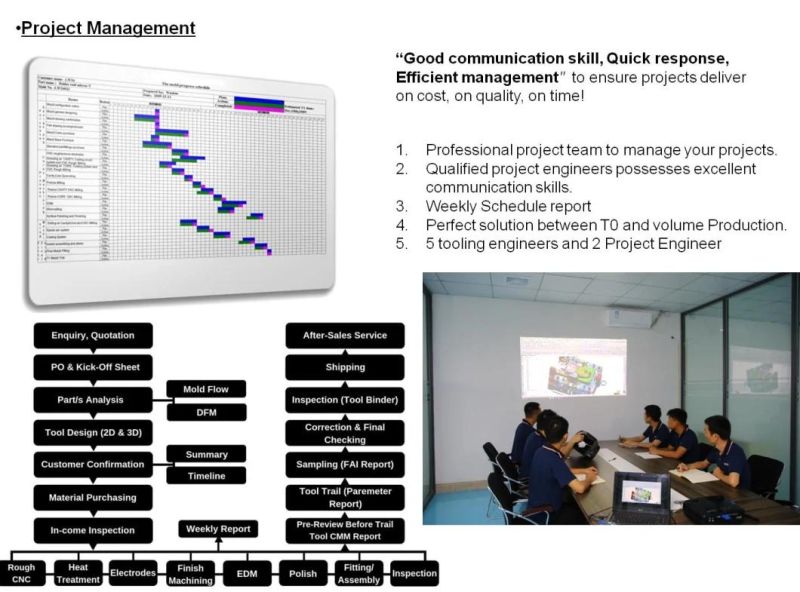

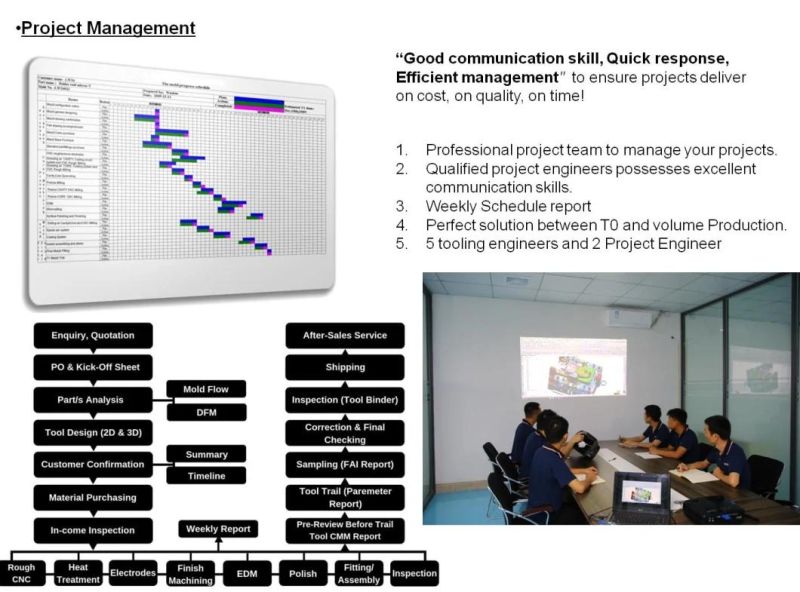

Mold making process

| 1.Sample/Drawing | After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis. |

| 2.Negotiation | Material, cavity, price, delivery time, payment term etc. |

| 3.Place Order | when all terms are agreed by both sides, then we will accept an order. |

| 4.Mould Design | Our R&D team will design the mould per customer requirements and send drawings for approval. |

| 5.Tooling Mould | Once the mould design is approved will start mould tooling. |

| 6.Mould Process | CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. |

| 7.Sample Confirmation | Send samples for confirmation, if not approved we will adjust the mould structure. |

| 8.Mass Production | After the customer approves the sample, we will arrange mass production. QC will inspect after products finished. |

| 9.Package | PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing. |

| 10.Delivery | By sea or by air according to customer requirement. |

| 11.After-sales Service | Ready to help customers solve any possible problems. |

Company profile

Our team

Quality control

Our services

Our workshop

Packaging detail

Customer Visit

FAQ :

Q1: What kind of molds do you make?

A1: We are mainly making plastic mold injection and Die casting mold.

Sometimes we also make rubber molds according to our customer's requirements.

Q2: What types of files do you accept (drawings)?

A2: With our CAD systems we can accept the following files:

STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q3: What kind of steel do you use for plastic mouldings?

A3: We can use any type of steel appointed by customers or popular in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc.

Q4: Can you provide the steel certificate and heat-treatment certificate?

A4: Yes, We can provide a steel certificate or hardness certificate to prove.

Q5: Can you make the texture/text/heat_treatment /nitriding for the injection mold plastic?

A5: Yes, As a plastic mold factory, we have long term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q6: How long is the lead-time for a plastic injection mold?

A6: It all depends on the mold's size and complexity. Normally, the lead time is 25-45 days.

If the Plastic Mouldings are very simple and not big size, we can work out within 15 days.

Q7: Do you make spare parts for your customer?

A7: Yes, we will provide spare parts for the mold if needed or required by clients.