Multi Cavities Custom Electronic Shell Plastic Injection Mould Die Makers

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:PET

- Mould Cavity:Single Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Lead-Time:15-45 Working Days

- Advantages:10 Years Experience

- Mould Process:Grinding, Milling, Drilling, etc.

- Mold Life:1million Times

- Mold Base:Lkm or According to Customer Requirements

- Quotation:According to Samples, Drawing and Specific Require

- Cavity:Will Basis on Qty Plan and Customer′s Requirements

- Steel Material:718, 8407, Nak80, H13, S136, P20, DIN 1.2738, DIN

- Gate Type:Pin Point Gate, Edge Gate, Side Gate, Sub Gate

- Customized:Customized

- Standard:PUNCH

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Injection Machine Tonnage:50t-3600t

- Transport Package:Wood Box

- Specification:According to your drawing

- Trademark:OEM

- Origin:Guangdong, China

- HS Code:8480719090

- Production Capacity:8000,Day

Description

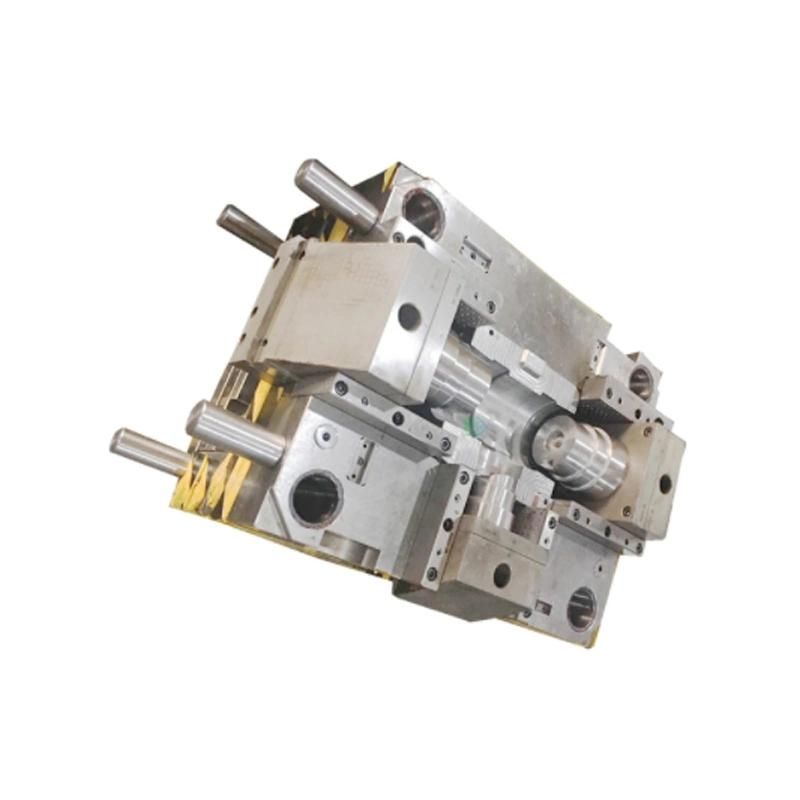

PLASTIC INJECTION MOULD BASIC DESCRIPTIONDesign Capability DFM,Mould flow analysis,Product optimization, Full 2D & 3D mould design,Reverse engineering,Collaborative design with customer's idea Ejector System Stripper plate,Lifter,Push bar,Ejection pin etc Inserts(cavity and core) H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or as your request Injection System Hot /Cold Runner Mold Cavity 1*1,1+1,1*2,1+1+1,etc Gate type Side gate,Sub gate,Pin point gate,Edge gate etc Steel for Mould P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344, etc. Steel Standard FINKL,Assab,DAIDO,LKM,Buderus Cooling Baffles/Sprin Piple/3D printing water line Lead time of first samples Around 4~7weeks Standard Parts/Cylinders DME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/Merkle Documents / Reports Provided Fully drawing,Weekly Processing Report, Steel Dimension report, Processing Report,Sample Dimension Report.

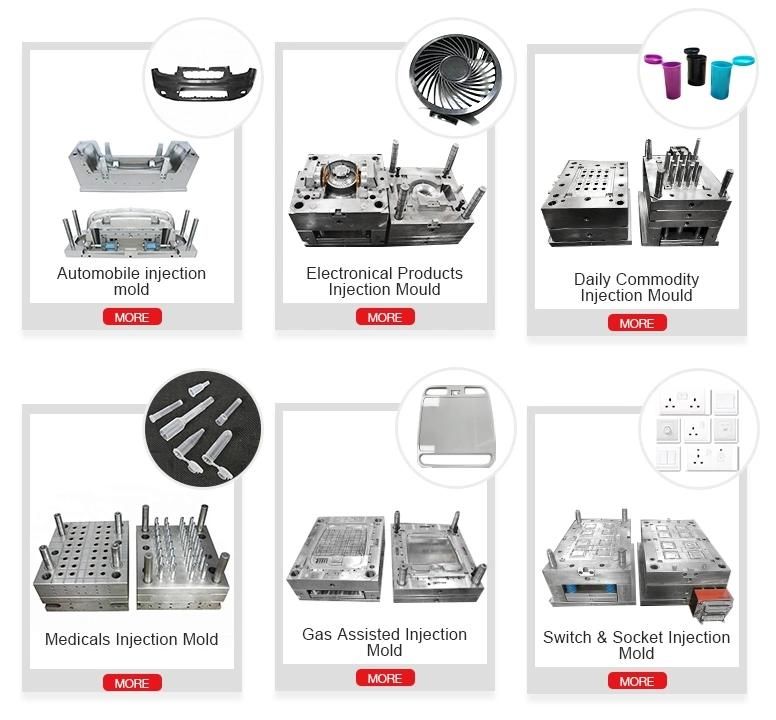

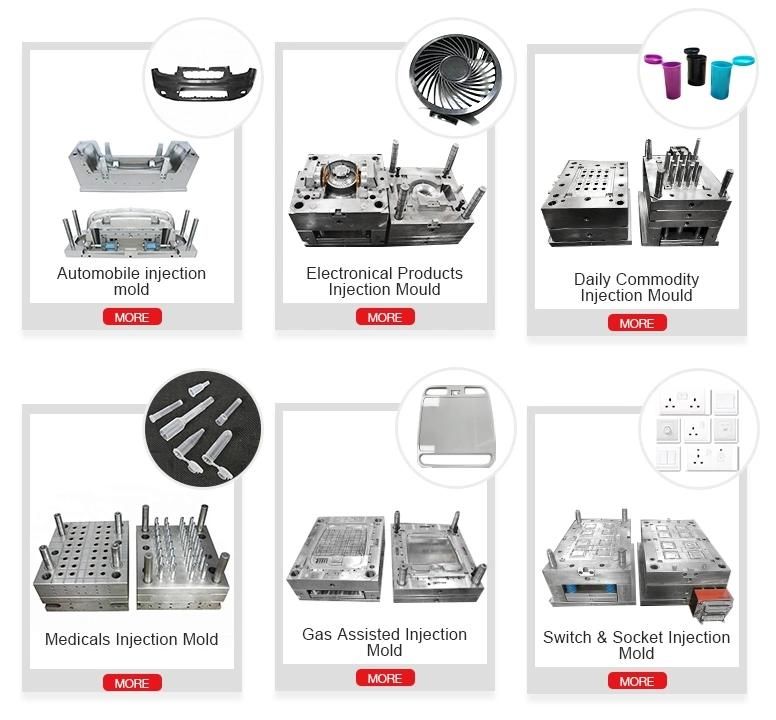

Other products:

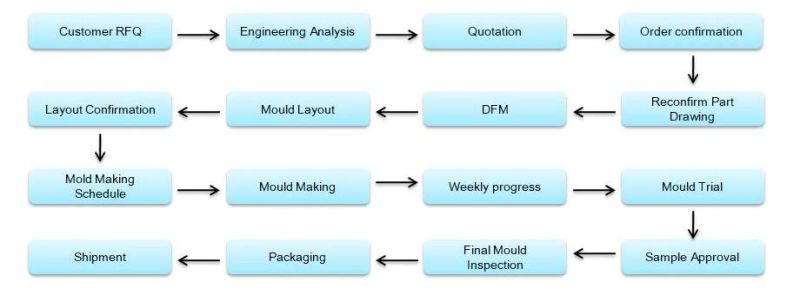

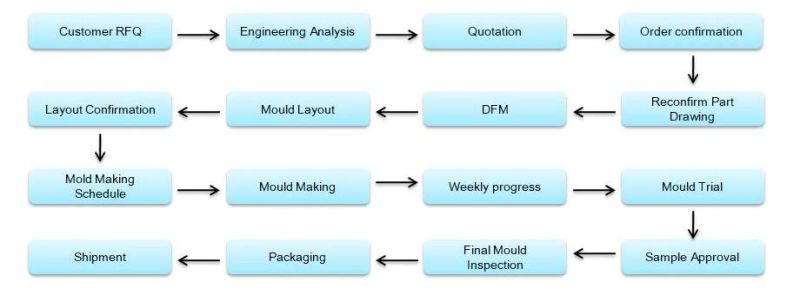

Project Management Process:

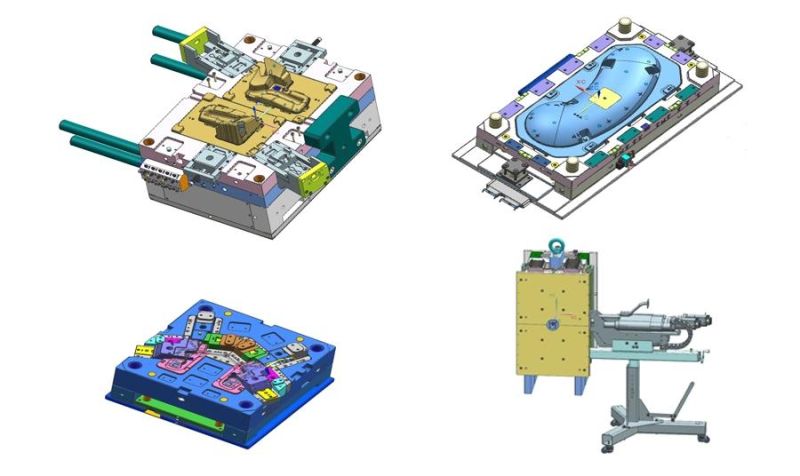

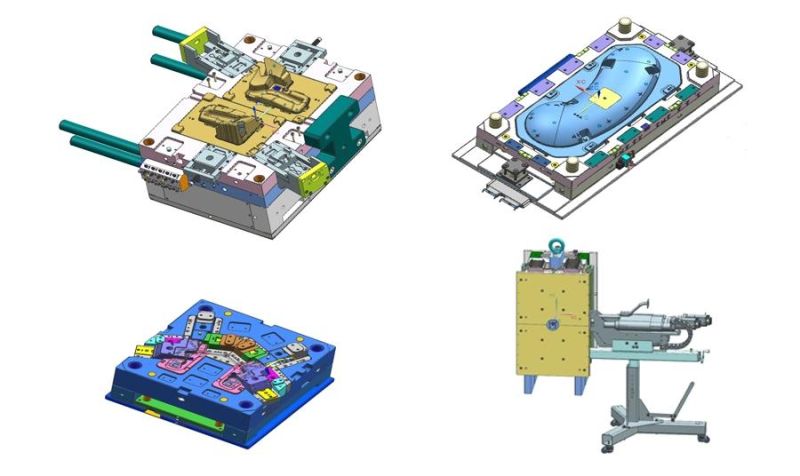

Mould Design Drawing:

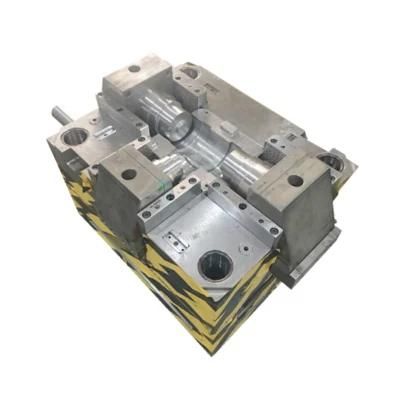

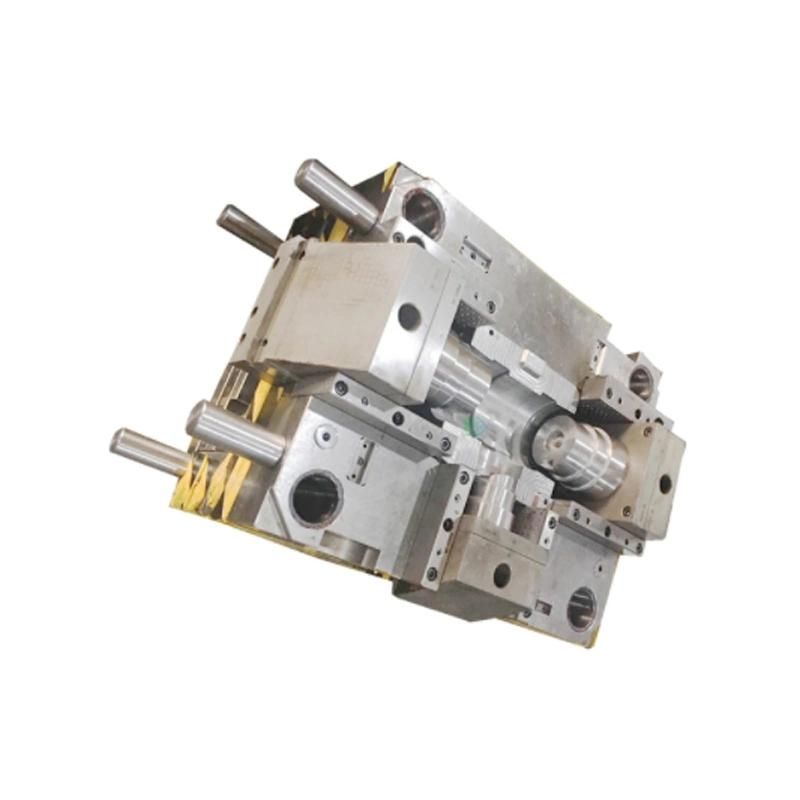

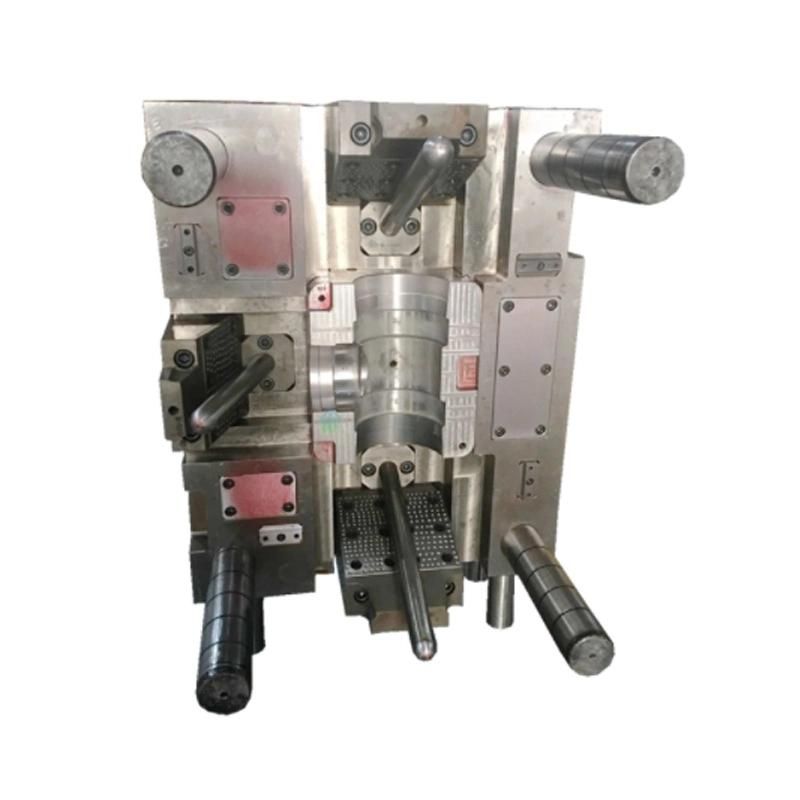

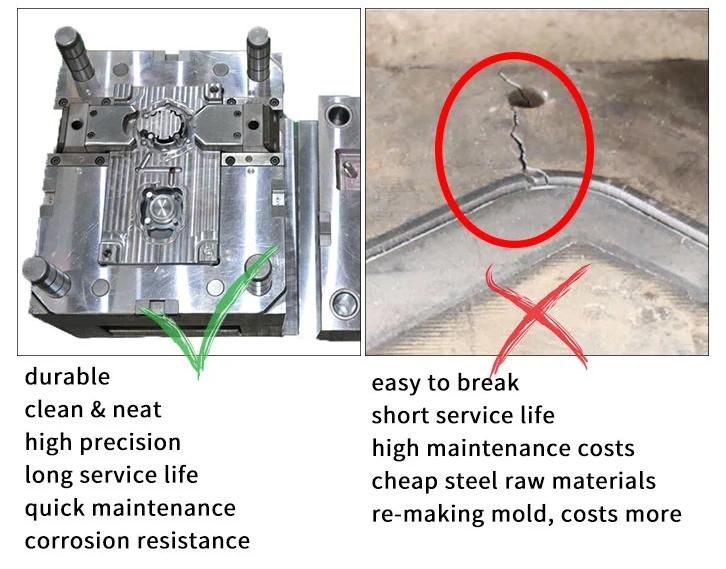

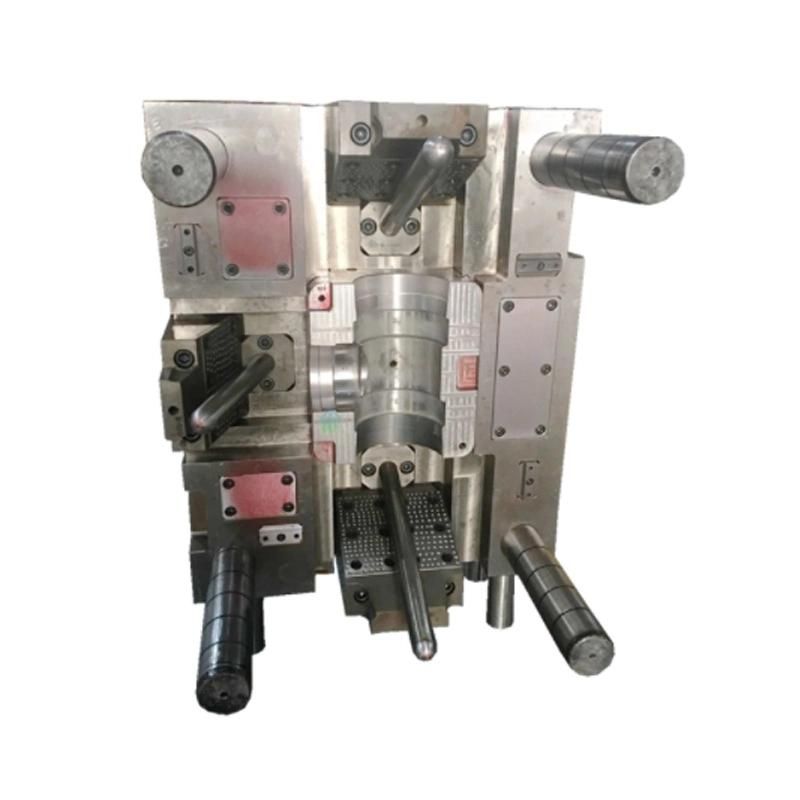

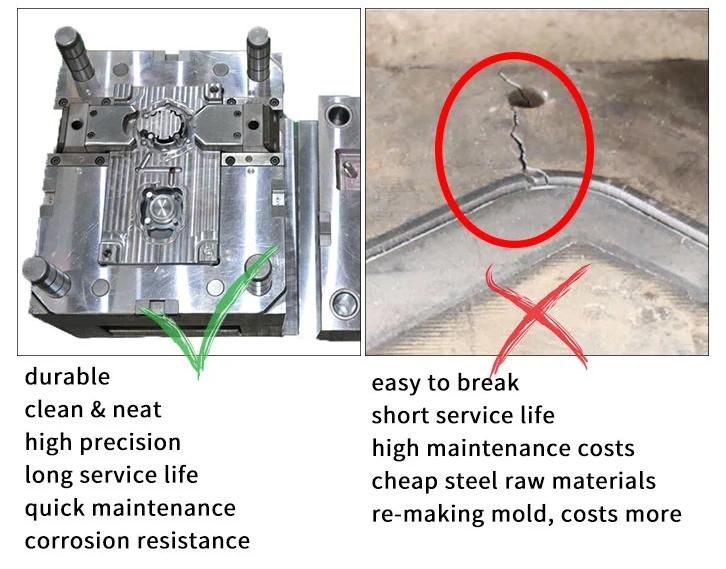

Our Mould is on the Left as following:

Company Profile:

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 10 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Committed to providing one-stop services from prototyping through toolings to high-volume product production with competitive price and short lead time based on advanced technologies, scientific management and continuous improvement.

Family Culture:

Plastics Components Parts Showroom:

Customer Visiting:

Advantage:

1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 13 years.

2. Long term cooperation with some Top Brand Auto Industry, such as Volvo.

3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification.

4. Equipment includes CNC, EDM, grinding machine, injection machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products .

5. We offer unique solutions to your products at a competitive price and best service.

6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold.

7. Your products will enter the supermarket, we can design a package for you.

8. Quick mold making and on-time delivery.

9. We accept small order quantity, look forward to receiving your inquiry.

10. Excellent R&D teams, Professional technicians and rich experienced workers

11. Providing good After-sale service, if the products have any quality problems, we will take charge of it.

Packing & Shipping:

Other products:

Project Management Process:

Mould Design Drawing:

Our Mould is on the Left as following:

Company Profile:

Howe Precision Mold Co. is a qualified engineering and manufacturing company that designs and makes production tools of high-quality injection mold and die-cast mold for plastics molding and metal casting in wide ranges of automotive, household appliances, consumer goods, etc., with an engineering team over 10 average years of experience. Established in Dongguan City China, by the general manager Mr. Shawn Lee with the technical backgrounds.

Committed to providing one-stop services from prototyping through toolings to high-volume product production with competitive price and short lead time based on advanced technologies, scientific management and continuous improvement.

Family Culture:

Plastics Components Parts Showroom:

Customer Visiting:

Advantage:

1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 13 years.

2. Long term cooperation with some Top Brand Auto Industry, such as Volvo.

3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification.

4. Equipment includes CNC, EDM, grinding machine, injection machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products .

5. We offer unique solutions to your products at a competitive price and best service.

6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold.

7. Your products will enter the supermarket, we can design a package for you.

8. Quick mold making and on-time delivery.

9. We accept small order quantity, look forward to receiving your inquiry.

10. Excellent R&D teams, Professional technicians and rich experienced workers

11. Providing good After-sale service, if the products have any quality problems, we will take charge of it.

Packing & Shipping: