LPG Cylinder Handle Forming Moulds

Shandong Getweld Machinery and Equipment Co., Ltd.- Process Combination:Single-Process Mould

- Technics:Forming Die

- Processing Method:Punching and Shearing Mould

- Material:Hard Alloy and Steel Bonded Carbide

- Application:LPG Cylinder Production

- Manufacturing Technology:Computer Technology

Base Info

- Trademark:GETWELD

- Specification:Size: customized

- Transport Package:Exportable Wooden Box

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:Normal Speed

- Mold Cavity Technology:EDM Milling

- Driving Motor Type:Permanent Magnet

- Model NO.:Handle mold

- Origin:China

- HS Code:8207209000

- Production Capacity:1000pieces,Year

Description

Basic Info.

Model NO. Handle mold Driving Motor Type Permanent Magnet Mold Cavity Technology EDM Milling Milling Speed Normal Speed Parts Detection Method Measurement of Three Axis NC Transport Package Exportable Wooden Box Specification Size: customized Trademark GETWELD Origin China HS Code 8207209000 Production Capacity 1000pieces/YearProduct Description

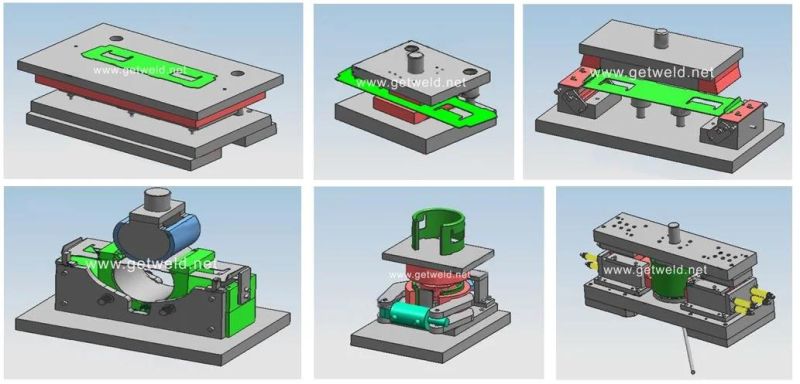

LPG cylinder handle forming mouldsLPG cylinder handle is formed after several processes. The steel coil is de-coiling and flattening, then it is feeding to the blanking machine, next is info. stamping, then vertical edge bending, pressing rolling, upper edge bending, and last is the handle bending.The whole set of handle forming moulds mainly contains the blanking mould, the stamping mould, the vertical edge bending mould, the rolling mould, the upper edge bending mould, and the handle bending mould.

Getweld mould is professional in the stamping dies, especially in electric water heater tank, air conditioner shell, oven shell, cooker hood, electric pressure cooker, rice cooker, LPG cylinder, air compressor tank, Dura cylinder production. We can make and design stamping dies for all of these products. With more than 16 years of professional experience in mold design and manufacture, we have established the full process from proto-type samples quantity production quality control. Provide a one-stop solution for our customers, from design manufacture to technology support. We are good at progressive die, single die and compound die.