Heavy Duty Stamping Line for Car Manufacturer Plant 1000t Line

Zhejiang Jinaolan Machine Tool Co., Ltd.- Material:Cr12MOV

- Processing Method:Punching and Shearing Mould

- Application:Household Appliances, Electronic, Hardware, Car, Commodity, Home Use

- Warranty:2

- Technics:Cutting Die

- Process Combination:Progressive Die

Base Info

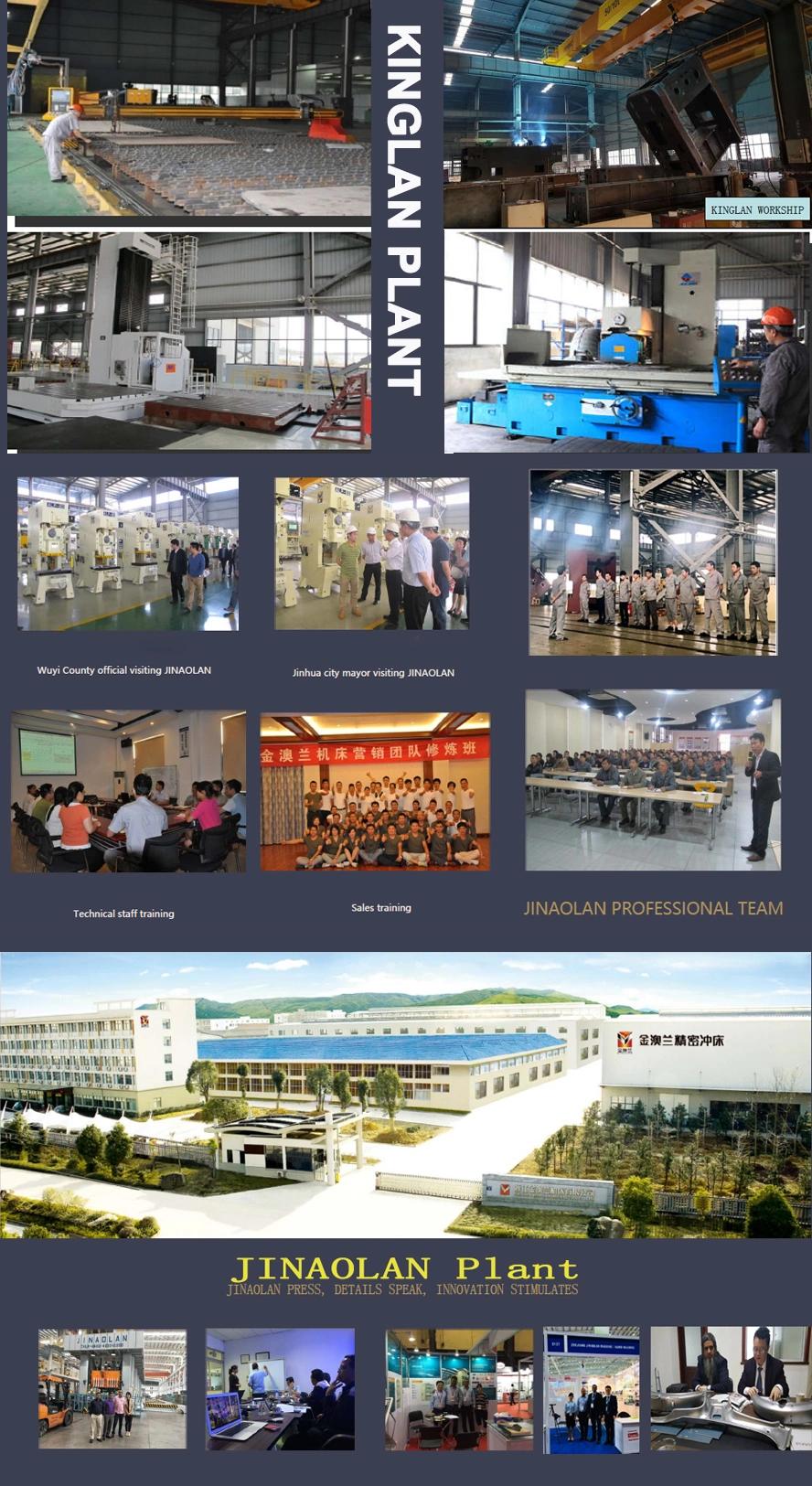

- Trademark:KINGLAN

- Transport Package:Standard Export Package

- Manufacturing Technology:Automation Technology

- Origin:Wuyi, Zhejiang

- HS Code:82072010

- Production Capacity:500PCS Per Month

Description

Project Description

Our produced products

Punching machine

Certificate

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing stamping machines for more than 35 years.

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers' incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

Q1: What about the after-sale service and installation?

A3: We provide on-line guidance or filed service ---our engineers are available to service machinery overseas in if customers required of it.