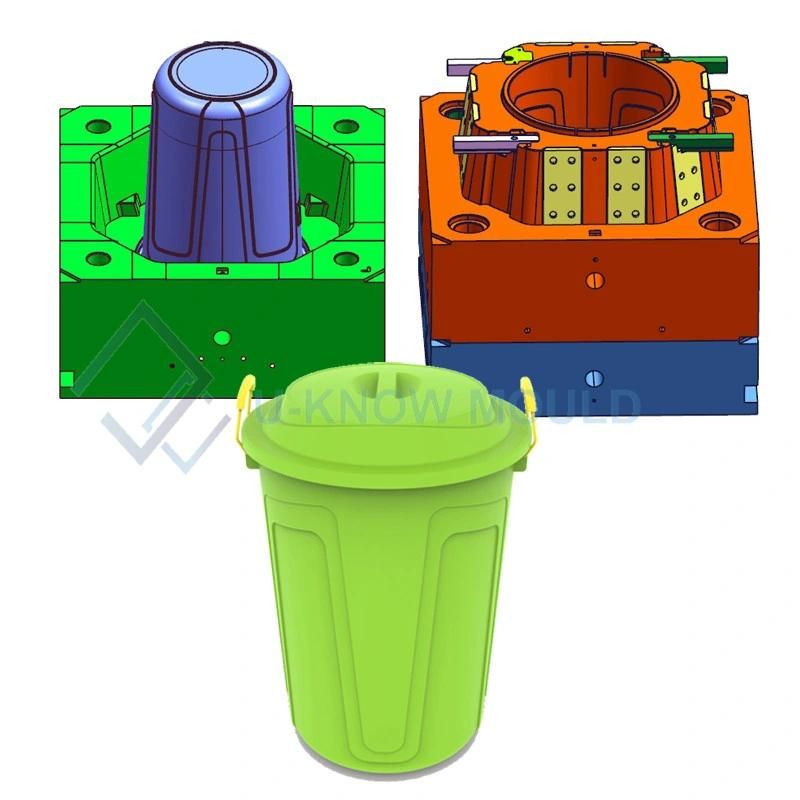

10L/30L/50L Customized Plastic Bucket Mould with Cover/Plastic Water Bucket Mold

TAIZHOU U-KNOW MOULD CO., LTD.- Application:Household Appliances, Furniture, Commodity, Home Use

- Plastic Material:PP, PC, PS, PE, PU, PVC, ABS

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Runner:Hot,Cold Runner

Base Info

- Specification:45#, P20, H13, 718, 2738, NAK80, S136etc.

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Model NO.:UKB026

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:500 Sets,Year

Description

Basic Info.

Model NO. UKB026 Design Software UG Installation Fixed Certification ISO Standard HASCO Customized Customized Transport Package Wooden Case Specification 45#, P20, H13, 718, 2738, NAK80, S136etc. Trademark UK Origin China HS Code 8480719090 Production Capacity 500 Sets/YearProduct Description

Product DescriptionThrough accumulating many years of making plastic injection bucket mould,we find the eccentricity of the plastic bucket mold tends to result in uneven thickness of the barrel. If the cooling water flows unevenly in the core area and the cavity of the barrel, it will cause a difference in the flow of the plastic melt. The smaller the fluidity in the cold area, the larger the fluidity of the area.And the larger the hot spot area on the side of the barrel will be a little thick. Therefore, We will pass the drop test and the leak test many times.

Q/C Inspect Moulds:

- Mould Material Q/C - Mould Steel Checking(Hardness, Crack ,Blow hole material defects ) - Mould Standard Spare Parts Checking(hardness, size, flaw checking)

- Mould Machining Process Q/C - Design checking (Part design, mould design,Including 2D drawing and 3D drawing) - Each part of mould's size checking after machining according to 2D drawing - Mold Test (check mould running conditions and T1 samples)

- Make sure to follow and checking each points of customer's request before shipment

Product Line

1. get the offer,discuss with the customer to confirm the details(the steel,cavity,runner,etc)

2.place the order,get the deposit

3.send the drawing to customer to check and radiate

4.produce the mould,send the mould process to customer each Monday

5.send the mould test video and samples to customer

6.get the balance,then make delivery

7.after-sale service

Company Information

U-KNOW MOULD is located in Huangyan,Zhejiang,China.It is known as one of the best manufacturers and exports for all kinds of plastic mould for commodity items,such as chair mould,crate mould,bucket mould,medcial mould and so on. We are a full rang of CNC machining centers,large gantry milling machines,vertical milling machines,CNC engraving machines,electric spark(EDM),wire-cutters,ect.We have advanced technologies fir CAD/CAM/CAE design and rich experiences in mould making.We have 5 senior designer and 20 engineers who have more than 15 years experiences in mouldmaking. Our designers are good at designing new products and mould structure.We always focus on perfection on quality and services.We would like to supply our best services and our best products to all the customers.

Packaging & Shipping

- Mould surface of core and cavity will be covered by antirust

- The mould surface will be covered by butter

- The mould will be packed by plastic membrane

- The mould will be put into wooden case

- Some other spare parts will be put into the wooden case together with mould, there are lifting bolt, water nozzle, water hose. Ejector-pin etc.