Plastic Portable Environmental Protection Lunch Box Mold/Plastic Food Container Mould

TAIZHOU U-KNOW MOULD CO., LTD.- Process Combination Type:Single-Process Mode

- Plastic Material:PP

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Furniture, Commodity, Home Use

Base Info

- Specification:45#, P20, H13, 718, 2738, NAK80, S136etc.

- Transport Package:Wooden Case

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot,Cold Runner

- Model NO.:UKC011

- Trademark:UK

- Origin:China

- HS Code:8480719090

- Production Capacity:500 Sets,Year

Description

Basic Info.

Model NO. UKC011 Runner Hot/Cold Runner Design Software UG Installation Fixed Certification ISO Standard HASCO Customized Customized Transport Package Wooden Case Specification 45#, P20, H13, 718, 2738, NAK80, S136etc. Trademark UK Origin China HS Code 8480719090 Production Capacity 500 Sets/YearProduct Description

Product DescriptionWith the acceleration of the pace of modern life, simplicity and convenience have become the mainstream style of society. Many plastic food container mould produced by U-KNOW MOULD can meet people's needs. Applications range from small to large, from round, square to oval. At the same time, we also produce thin-walled container molds of different sizes. We provide high quality and low cost mold products through the latest technology system.

Our Advantages

1.Capacity: Your design

2.good quality and competitive price

3.various color to choice

4.blow molding processing

5.Logo and label can be printed

6.OEM is available,we can also manufacture products according to your picture or samples.

Product Line

About Us

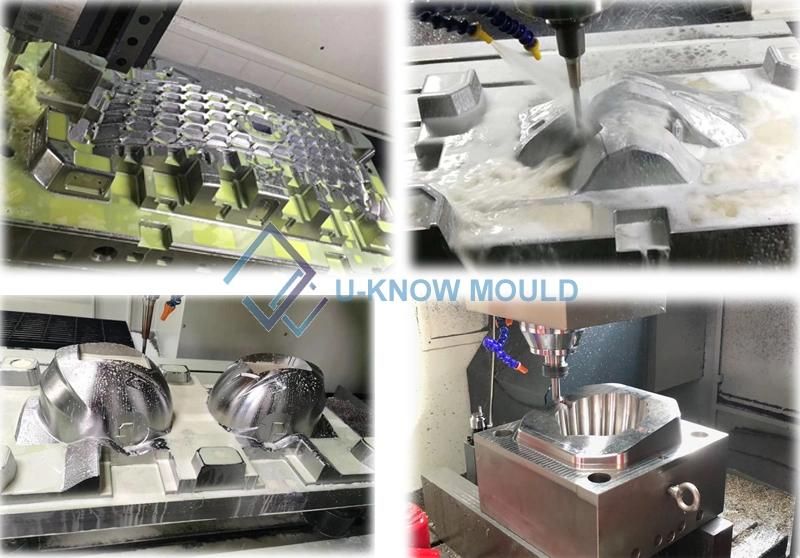

U-KNOW MOULD is located in Huangyan,Zhejiang,China.It is known as one of the best manufacturers and exports for all kinds of plastic mould for commodity items,such as chair mould,crate mould,bucket mould,medcial mould and so on. We are a full rang of CNC machining centers,large gantry milling machines,vertical milling machines,CNC engraving machines,electric spark(EDM),wire-cutters,ect.We have advanced technologies fir CAD/CAM/CAE design and rich experiences in mould making.We have 5 senior designer and 20 engineers who have more than 15 years experiences in mouldmaking. Our designers are good at designing new products and mould structure.We always focus on perfection on quality and services.We would like to supply our best services and our best products to all the customers.

Packaging & Shipping

- Mould surface of core and cavity will be covered by antirust

- The mould surface will be covered by butter

- The mould will be packed by plastic membrane

- The mould will be put into wooden case

- Some other spare parts will be put into the wooden case together with mould, there are lifting bolt, water nozzle, water hose. Ejector-pin etc.