Threaded Plastic Parts Manufacturing Hydraulic Motor Driven Auto Unscrewing Mould

Shenzhen Mingyang Yutong Technology Co., Ltd.- Process Combination Type:Precision CNC Milling, EDM Machining, CMM Testing

- Plastic Material:PE

- Mould Cavity:Multi Cavity

- Surface Finish Process:Texture

- Warranty:2 Years

- Shaping Mode:Injection Mould

Base Info

- Transport Package:Crate Box with Vacuum Packaging for Mold

- Standard Parts:Dme

- Gating:Cold Runner

- Mold Construction:Inserted Cavity & Core

- Mold Base Steel:1.2738

- Mold Steel:1.2344

- Water Connector:Dme

- Customized:Customized

- Standard:HASCO

- Certification:ISO, SGS

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Application:Car, Electronic, Home Use, Hardware

- Model NO.:GBM003

- Specification:Unscrewing Mould, Motors driven

- Trademark:GBM Mold

- Origin:Shenzhen

- HS Code:84807100

- Production Capacity:250 Sets,Year

Description

If you are looking for a tool maker to handle your projects smoothly, to help you achieve an early good result, contact us now!

Since 2010, GBM started to design and make plastic injection molds for North American and European customers. Many customers follow us from the very beginning, till now, and will be in the future...

Every project, we aim to deliver good results to customers by our tooling know-how.

"You can never go wrong from purchasing molds from GBM. Top level quality and service!"

--Yanfeng Automotive Interiors, US Tier 1 Supplier

" I think GBM are good for "difficult" and "high value" projects! "

--UK Molding Manufacturer

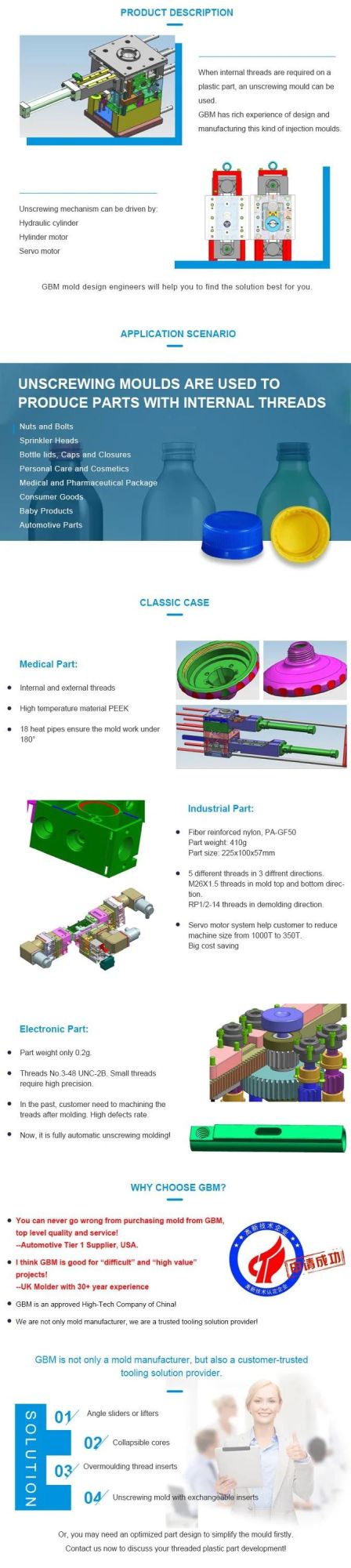

Our customers appreciate especially our knowledge of injection molds with precision inserts, unscrewing mold, 2-shot mold and insert mold, and our subsequent experience in process optimization.

Experience makes the difference.

If you are looking for a tool maker to handle your projects smoothly, to help you achieve an early good result, contact us now!

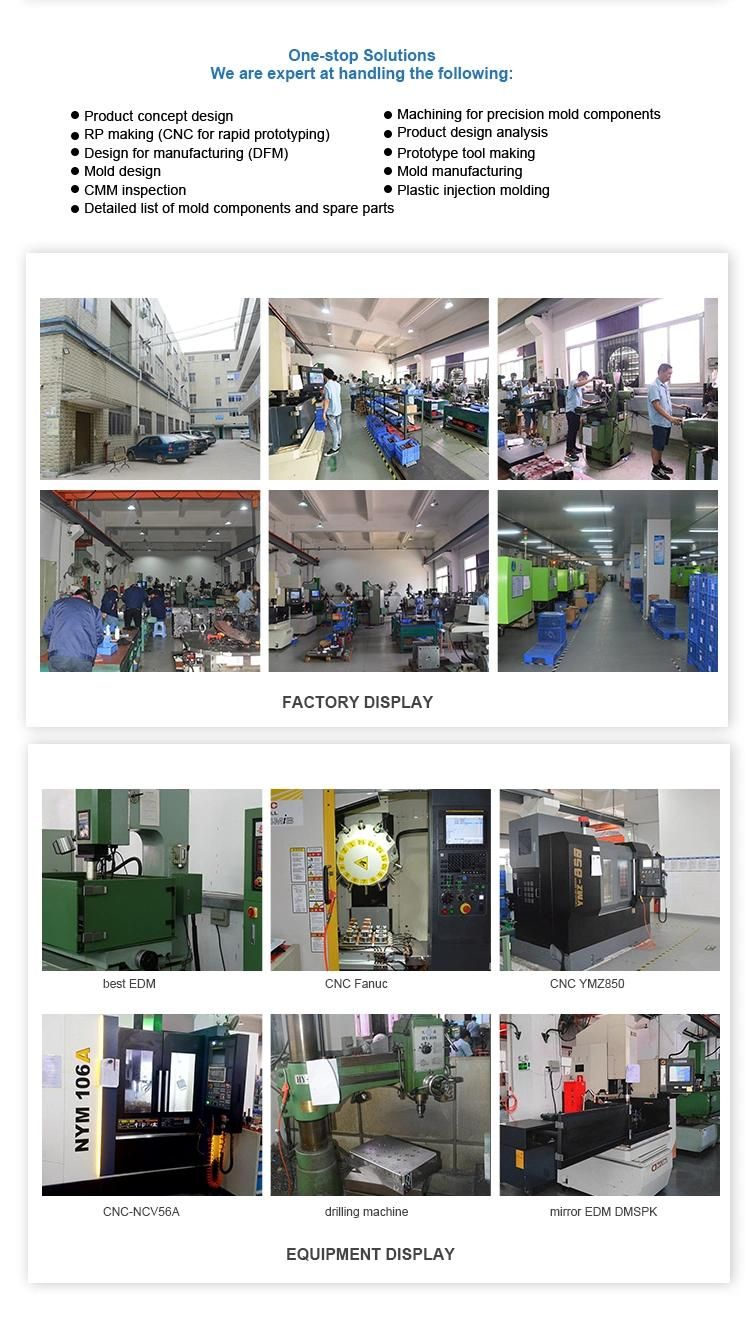

GBM Mold focus on small & medium-sized injection mold with complex construction. We have good experience of making molds as following:

1) Stack mould

such as 3-level stack mold

2) Two-shot mould (Multi-shot moulding, multi-material-moulding)

for normal 2-component parts and multi-component parts, like 2-component parts with additional metal inserts

3) Unscrewing mould

we are familiar with unscrewing system with hydraulic cylinders, hydraulic motors, or servo motors.

4) Insert molding

We have rich experience for making normal insert molding mold -One cover and one ejector side, and shuttle mold-One cover and two ejector side, also know as rotational insert mold.

For those parts/components with complex irregular consctruction, GBM Mold team could handle properly for you.

Work with GBM Mold:

1). Professional mold design as the production mould standards

2). Professional mold assembly staff with over 9 years experience

3). 2-shift fast manufacturing with CMM testing for each machining processes

4). Clear project schedule plan and on time delivery

5). Professional project management with efficient communication to make every minutes counts.

If you want more information about us or have any questions. Please feel free to contact me . (Jessie )

You are welcome to visit to our factory in Shenzhen of China.

GBM Mold get SGS certificate, and been approved as Hi-Technology Enterprise of China. A Hi-Technology Enterprise means the company need to have good R&D ability, continoued sales growth, healthy finance status. Therefore will be less risk for customers supply chain management.