Customized Automobile Metal Stamping Dies and Molds (Manufacturer Supplier Factory

Hehua Machinery Technology (Kun Shan) Co., Ltd.- Technics:Forming Die

- Process Combination:Progressive Die

- Processing Method:Punching and Shearing Mould

- Material:High Carbon High Chromium Tool Steel

- Application:Household Appliances, Electronic, Hardware, Car, Commodity, Home Use

- Manufacturing Technology:Automation Technology

Base Info

- Specification:According to your requirement

- Transport Package:Wooden Case

- Size:Customized

- Transport:by Sea or Air

- MOQ:1 Piece

- Certificate:ISO9001;Ts16949

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:High Speed

- Mold Cavity Technology:EDM Milling

- Driving Motor Type:Permanent Magnet

- Model NO.:HHM-415

- Trademark:HEHUA

- Origin:Shanghai

- HS Code:7201100000

- Production Capacity:100,Week

Description

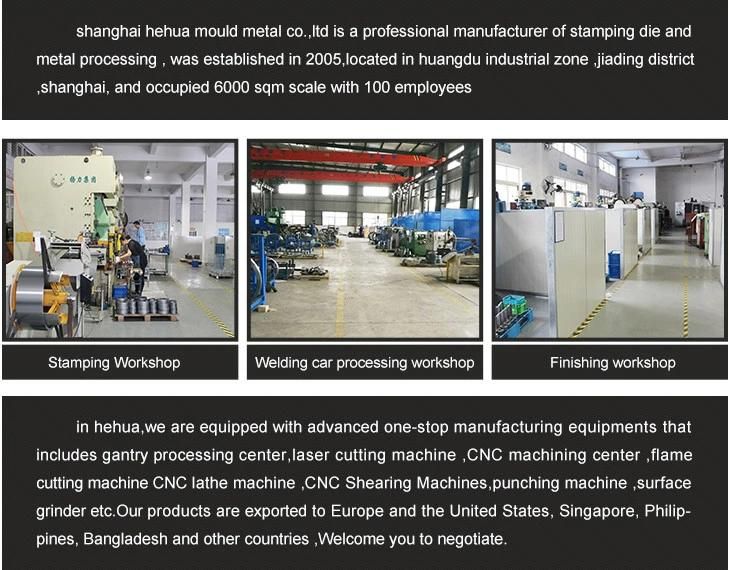

HEHUA is an OEM manufacturing factory .Mainly produce the stamping parts,sheet metal parts,mold making ,spark-erosion wire cutting,CNC machining ,laser cutting and welding.our company own various equipments about 100,such as :Gantry milling ,Laser cutting ,Bending machine Shearing machine,Punching machine 8T-200T,CNC Machining center,CNC Lathe machine,Milling machine ,Wire-electrode cutting ,Grinding machine ,Drilling machine,Threading machine ,Argon welder,Gas shielded welding machine ,Spot welding machine ,Squeeze riveter(Pressure riveting machine),Laser marking machine .Company has rich experience in mold design and excellent manufacturing capability, strict quality control system, for customers from product design, mould manufacture to the product production do unified service! And in August 2015 passed ISO9001:2008 quality certification system and TS16949:2009 certification system, our products are exported to Europe, America, Australia, Spain, Netherlands, Philippines, Italy, Japan and other countries.

Mainly client has ABB, SAINT-GOBAIN, Germany Continental, Faiveley, Ford, Mitsubishi, L&L , Tenneco and other well-known enterprises, for many years deep old customer recognition, on the basis of mutual benefit common development, to provide stable and reliable quality service to our customers.

Our Advantage:

1.Good Quality

2.Competitive Price

3.Long production history

4. International Quality Certified

5.Skilled workers

6.Prompt Delivery Time