Plastic Injection Molding Auto Light Housing Plastic Case (STK-PLS-007)

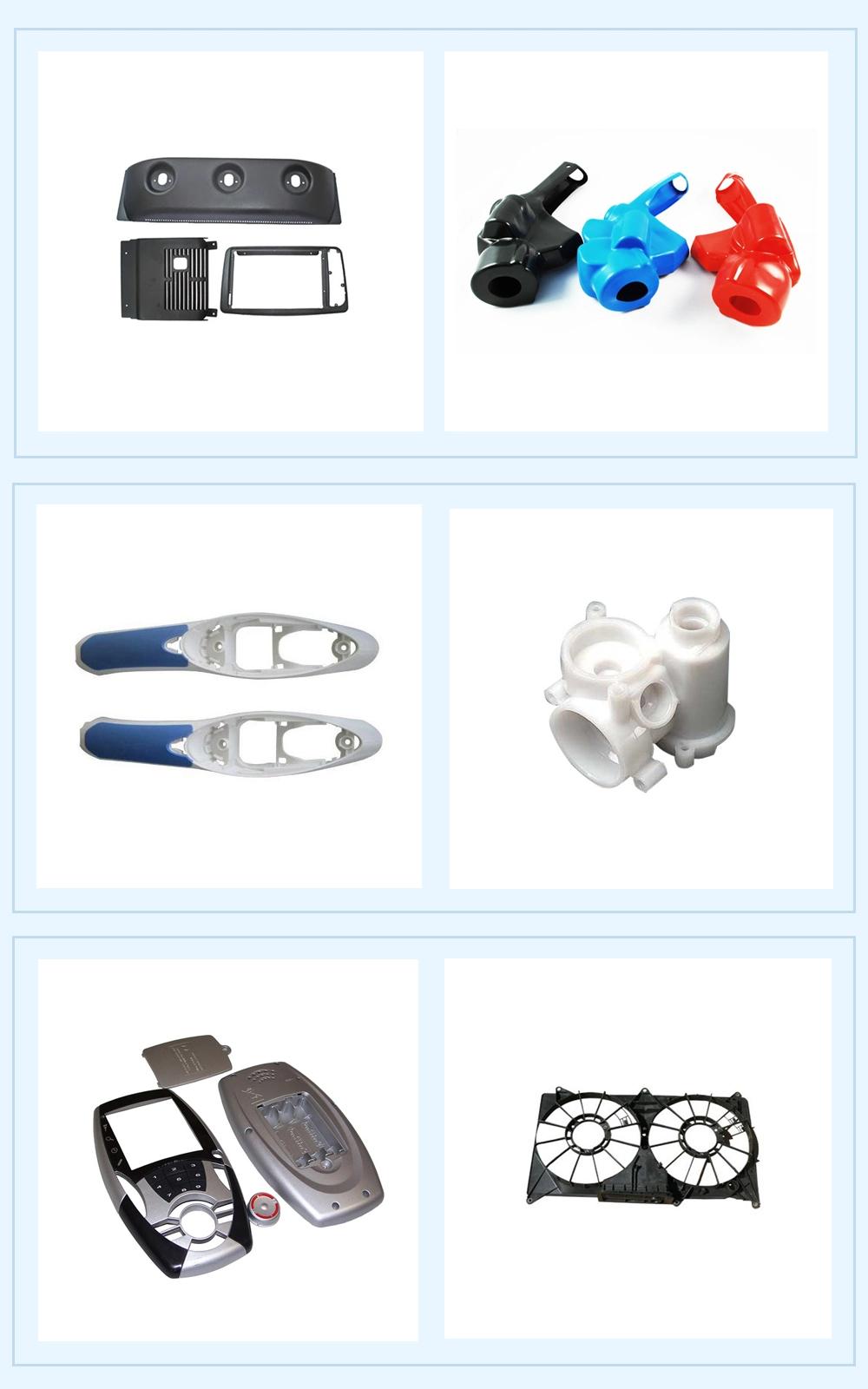

Xiamen Stick Industry Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware, Automotive, Gears, etc

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Quality:Professional Inspection

- Weight Available:0.02kgs to 5kgs

- Drawing Formats:Igs,Step,X-T,Pdf,JPG,Dxf,Dwg

- Payment:T T 50% Deposit

- Export Markets:Global

- Process:Injection Molding

- Material of Mould:Nak80, 738, 718, 718h, 2738, 2316, S136, H13, etc

- Lead Time:25-30 Days for Mold, at Least 10 Days for Products

- Surface Treatment:Chrome Plating, Silk-Printing, Laser Etching, etc

- Applications:Automotive, Bottles, Caps, Crates, Housings

- Material:PC, Pes, ABS, PA6, PA6,6, PBT, Pet, PVC, HDPE

- Drawing:CAD, Cam, Cae, Solid Works, Caxa, Ug

- Machine:15 Ton to 320 Ton

- Mold Shot Weights:0.1 Gram to Over 750 Gram

- Customized:Customized

- Standard:HASCO

- Certification:CE, ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:STK-PLS-007

- Free Sample:Availble

- Transport Package:Standard Export Package

- Specification:Customized

- Trademark:Customized or STK

- Origin:China

- HS Code:79070090

- Production Capacity:500000PCS,Month

Description

Plastic Materials Applies:

Company Information:

Our main production area is equiped with 40 molding machines of various size,

ranging from 80 tons to 1400 tons clamping pressure.

This provides us with teh capability to mold shot weights from 0.1 gram to over

10000 grams with flexible production runs.

Plastic Injection Solution:

* Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class production

* Parts are widely used: Industrial, Automotive, Electronics & Medical

Technical Skills - Development, Design Skills:

* Design Consultation & Assistance

* Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysis

* Material Selection Assistance

* Quick turn-around prototype support

* Secondary Operations including machining, welding & assembly

Molding - High Precision, High Concern:

* Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stamping

* 40 Molding machines from 80TONS to 1400TONS

* High precision molding from medical to fiber optics components

Secondary Operations - Value Added Service:

* Pad Printing

* Sonic Welding

* Assembly & Packaging

Packing:

Our product you may like:

Plastic Injection Equipment List:

Certificate:

FAQ:

Q1. Can I have a sample order ?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What's your packing?

A:Full consideration of practical situation: foam/wooden box, anti-rust paper, small box and carton, etc.

Q3. Do you have any MOQ limit for order?

A: Low MOQ, 1pc for sample checking is available .

Q4. What do I need for offering a quote ?

A: Please offer us drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q5. Are you trading company or manufacturer ?

A:We are factory, with about fifteen years experience of mould design and mold making, production. We are 12 years Gold Supplier of Alibaba.We have established the quality management system conforming to ISO 9001:2008.We are absolutely worth your trust.

Q6. How long will it take for production?

A: It depends on the quantity and the complexity of the products you want.But the normal products we ensure can deliver on the day when you pay the money.

Q7: Do you accept customized?

A: Of course. Mould is a customized project. You can tell us your request about mould material, color, size and so on.

Q8: What is your terms of payment?

A: Mold :50% deposit +50% after the samples is approved.

Batch production: 30% deposit +70% before shipment.