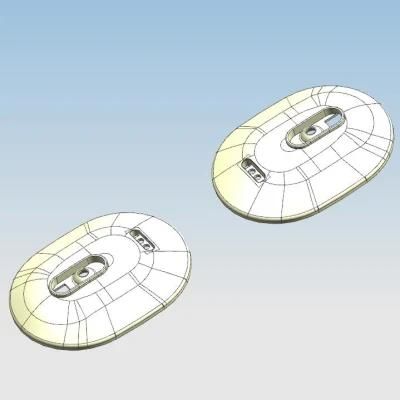

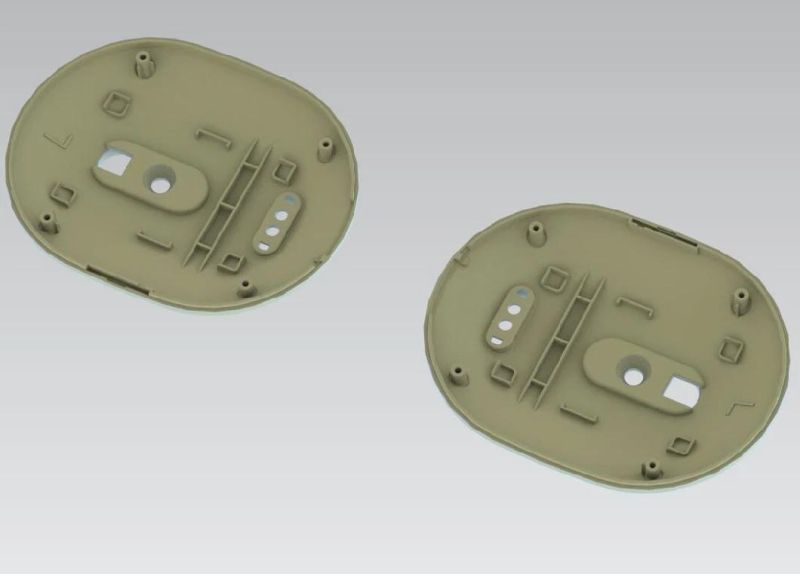

Design and Manufacture of Injection Mold for Plastic Shell of Consumer Electronics

Sum Shun Plastic Moulding (ShenZhen) Co., Ltd.- Plastic Material:PC

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Warranty:Negotiated

- Process Combination Type:Single-Process Mode

Base Info

- Customized:Customized

- Certification:ISO

- Standard:Spi-Class 103

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Application:Household Appliances, Commodity, Electronic, Home Use, Hardware

- Model NO.:HOU-L

- After-sales Service:Negotiated

- Spi Calss:103

- Type:Plastic Injection Mold

Description

Basic Info.

Model NO. HOU-L Application Household Appliances, Commodity, Electronic, Home Use, Hardware Runner Cold Runner Design Software UG Installation Fixed Certification ISO Standard Spi-Class 103 Customized Customized After-sales Service Negotiated Spi Calss 103 Type Plastic Injection MoldProduct Description

We have been engaged in plastic mold and plastic products export services, we have been engaged in this service for 21 years, our clients come from many countries, like United States, United Kingdom, Spain, Australia, Singapore, Russia, Japan, etc.

| Project Item | Injection Plastic mold |

| Mould making service | OEM/ODM |

| Design software | Pro/E, UG, Solidwork, Moldflow, AutoCad, etc. |

| Parts material | ABS, PC, PP, PBT, BMC, PMMA, PC+ABS, PP+TD20%, PU, PE, PVC..Etc |

| Cavity number | Single or Multi |

| Gate point | Edge gate, Slid gate,Sub gate,Direct gate, Pin point gate, Valve gate, etc. |

| Runner | Hot or Cold |

| Core & Cavity steel | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh, etc. |

| Mold base steel | 45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR |

| Mould base | LKM, DME, HASCO, ETC. |

| Injection machine | 90T-1500T |

| Cycle time | 10-120 seconds |

| Mould Life | 300,000 - 1,000,000 shots |

| Quality assurance | ISO 9001:2015,ISO 14001:2015 |

| Tooling lead time | 20-40 days |

| Shipping Packing | Wooden case or according to customer's requirement |

Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A. Yes! We are happy to work with potential customers to evaluate the technical feasibility of your ideas or design and we can advise on materials, tooling and set up the costs to you for reference.

Q. My components have been developed on CAD. Can you use the drawings?

A. Yes! We accept DWG, DXF, IGES, Solidworks and Rhino format's files, and will base on your drawings to quote and build up 3D products and mould toolings.

Q. Can I test my idea/component before committing to mould tool manufacture?

A. Yes! We are providing prototype service, can use CAD drawings to make models for functional evaluations and design improvement.

Q. Can you make the mold and also supply us the injection molding plastic product?

A. Yes! We provide molding, producing, painting, assembly and packaging service.