Strippit Amada CNC Punch Press Thin Turret Tooling

AFAB Machinery and Tools Ltd.- Processing Method:Punching and Shearing Mould

- Material:High-Speed Steel

- Application:Household Appliances, Electronic, Hardware, Car

- Technics:Cutting Die

- Process Combination:Composite Mould

- Manufacturing Technology:Automation Technology

Base Info

- Punch Assembly Length:140mm

- Die Hardness:HRC 58-60

- Punch Hardness:HRC 60-62

- Die Material:D2,SKD11

- Punch Material:M2,HSS,Skh51

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:Normal Speed

- Mold Cavity Technology:EDM Milling

- Driving Motor Type:Permanent Magnet

- Model NO.:THIN TURRET

- Transport Package:Plastic Box

- Origin:China

- HS Code:8207300090

- Production Capacity:50000PCS,Year

Description

Basic Info.

Model NO. THIN TURRET Driving Motor Type Permanent Magnet Mold Cavity Technology EDM Milling Milling Speed Normal Speed Parts Detection Method Measurement of Three Axis NC Punch Material M2/HSS/Skh51 Die Material D2/SKD11 Punch Hardness HRC 60-62 Die Hardness HRC 58-60 Punch Assembly Length 140mm Transport Package Plastic Box Origin China HS Code 8207300090 Production Capacity 50000PCS/YearProduct Description

THIN TURRET TOOLING suitable for Amada, Strippit,JFY

Thin Turret Tooling products range

Δ.Basic type is fully compatible with OEM popular series,Amada ,Mate original,Wilson metric.Best ecomonic type,save big cost.An economic ,Durablity,Performance,Lower cost type

Δ.FAB 90 type is a better tooling,Compatibale with wilson 90,Durability,Performance,Long grinding life,Quick adjust,Compatible with amada punch,Exchange with NEX,Quickadjust,Rapidset,No need tools to adjust punch

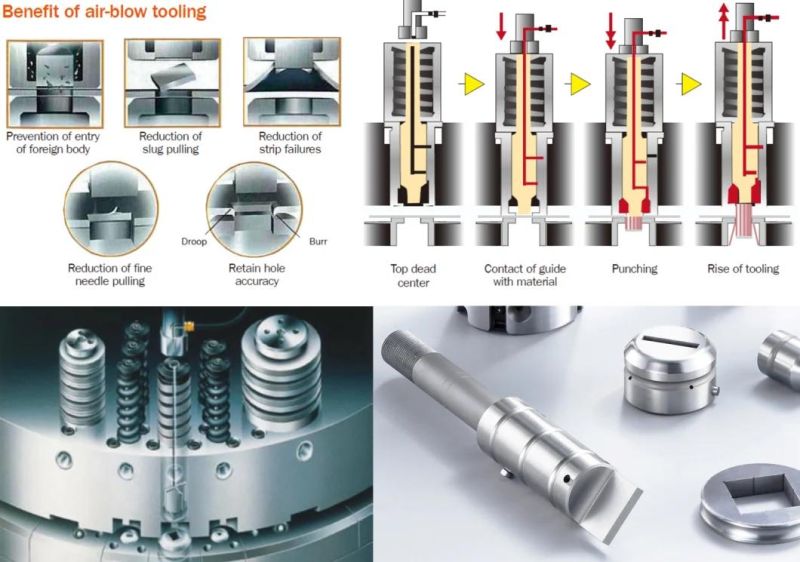

Air Blow system

Air blow system -ABS tooling maintains the tools whilst dramatically reducing the risk of tooling related machine stoppages.

Δ.Injects high pressure oil mist into the tool during punching cycle.

Δ.Lubricates all critical areas and surfaces.

Δ.Clears fine needles and slugs through the die after punching.

Δ.Effective in overcoming 'Cold Welding' or 'Microfusing

Δ.Ensures optimum tool life.

Δ.Maintains component quality

Punch material: M2-SKH51-High speed steel, Hardness HRC 60°-64°,Japan M2--JP M2 available,addons.

Die material:D2-SKD11, Hardness HRC 58°-60°

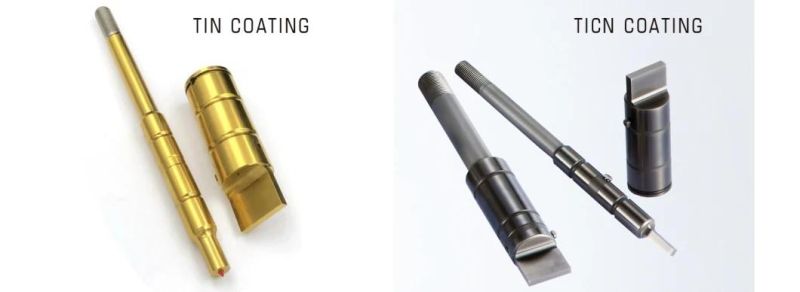

TIN/Maxima coating optional and vailable,improve double punch life

TICN/ Optima coating optional and vailable,improve four times punch life

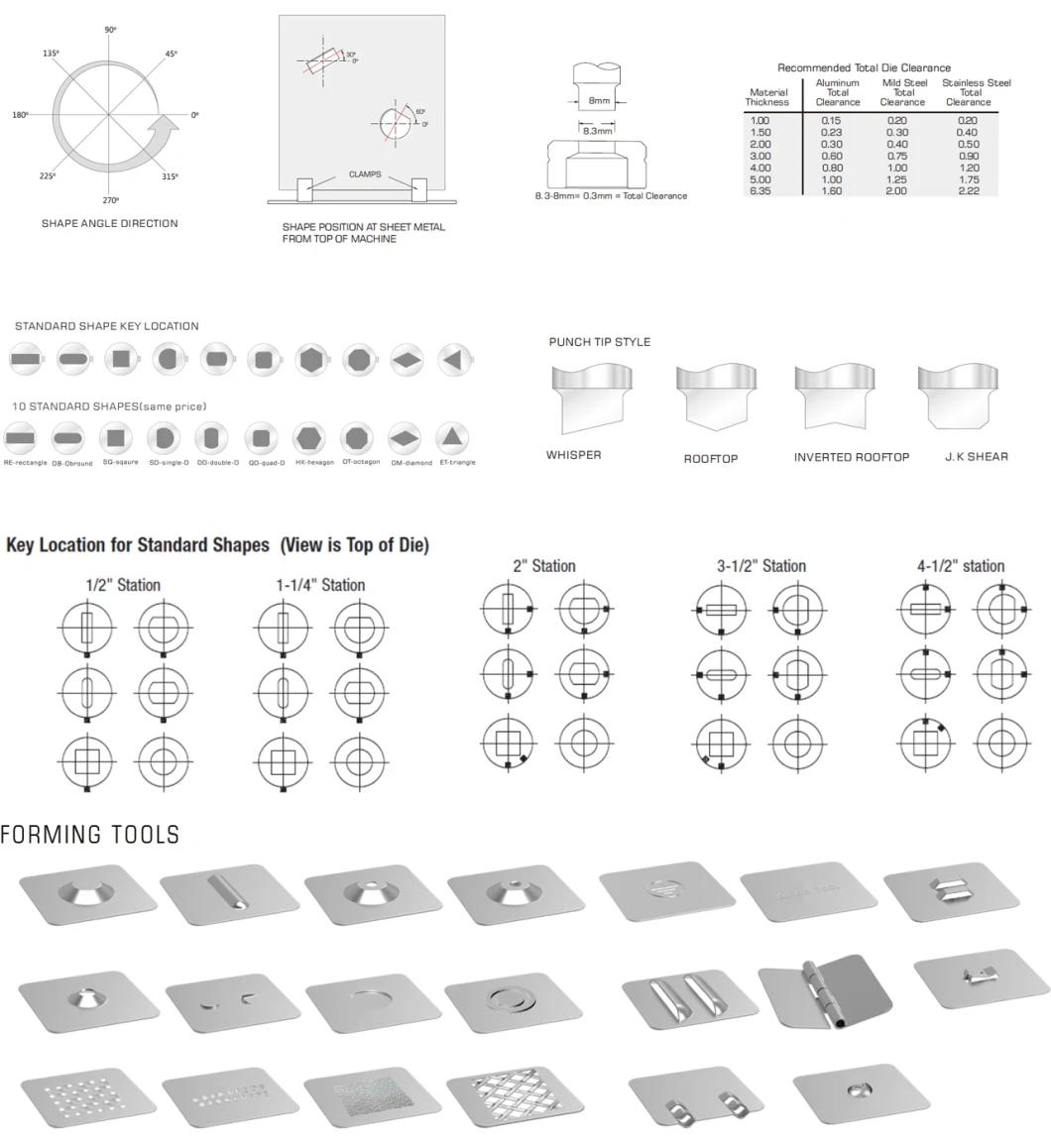

Standard shape:Rectangle,Square,Oblong,QR,QD,Single D,Double D,Hexagon,Octagon

FACTORY CAPACITY

AFAB Exhibition

Production leading time: Std shape 3-5 days, Special shape 4-5 days,Forming tooling 5-10 days.Coating need extra 3-4 days

Package: Extra thick carton or poly wood case. Deliver by DHL,TNT,UPS,FEDEX,AIRLINE