Plastic Concrete Interlocking Hollow Blocks Molds for Decorate Wall

Youxi Weipeng Plastic Mold Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PP (Polypropylene)

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Plastic Molding Die

- Application:Building & Bridge

Base Info

- Origin:Fuzhou Fujian

- Trademark:WP

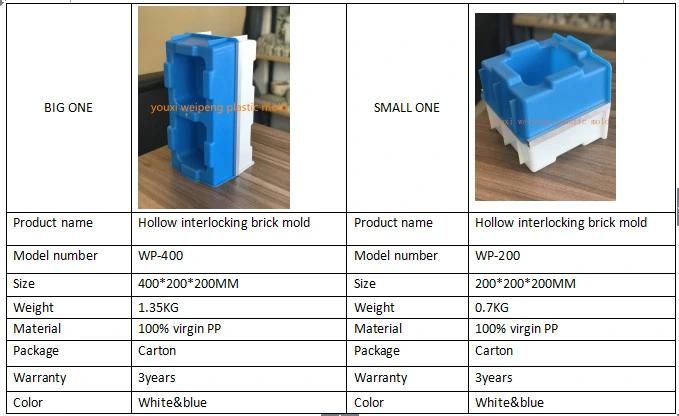

- Specification:400*200*200mm,200*200*200

- Transport Package:Cartons

- Customized:Customized

- Installation:Fixed

- Design Software:Pro-E

- Runner:Hot Runner

- HS Code:8480600000

- Production Capacity:2000PCS,Day

Description

Basic Info.

Runner Hot Runner Design Software Pro-E Installation Fixed Customized Customized Transport Package Cartons Specification 400*200*200mm/200*200*200 Trademark WP Origin Fuzhou Fujian HS Code 8480600000 Production Capacity 2000PCS/DayProduct Description

Brief Introduction

this is our new block mould design ,it can replace the normal block machine to produce the concrete blocks for your house building ,also then final block from this mould is with smooth surface and easy to paint and decorate the indoor and outdoor wall .most importantly ,this block can be 100% interlock together which will save more cementduring building and more stable struture for the whole house.

it can be used for a long time and just need a vibrating table and pan concrete vmixer then you can do producing ,it 's a perfect choice for a small amd medium-sized factory. You would like to know:

You would like to know:

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Environmentally friendly.

2. Many times faster to install than concrete kerbs due to reduced weight.

3. Can be handled, lifted and installed without machines.

4. Does not chip or crack; practically indestructible.

5. Resistant to UV, acids, petrol, oil, insects and plants.

How to demould smoothly and get strong blocks:

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

- The moulding oil should use the wasted engine oil.( Note: can't use diesel, which dry too quickly)

- To the demoulding time, you should demould when the concrete dry at a certain degree,at which degree, the concrete is concreted,but won't stick on the mould when demould. (to this point, you can try several times to get the suitable idea.)

- To get the strong block, except the aboved points, you should vibrate to release the air, and make cement and other materials fasten each other.

About Size: Due to manual measurement, please allow slight error, make sure you do not mind before you enquiry/quote, please kindly understand, Thanks!

About shipping: We are offer worldwide shipping. SERVICE TRANSIT TIME is provided by the carrier and excludes weekends and holidays. Transit times may vary, particularly during the holiday season

About our serve: If you are interested in our products or any further question, please kindly feel free to contact with us at any time.

Our goal is customer satisfaction!

We accept OEM. Any other relevant concrete molds also can be manufactured by the samples or drawings.