Customized Automotive Progressive Die for Hardware Auto Stamped Parts/Pressings/Stampings ...

Qingdao Higrade Moulds & Products Co., Ltd.- Processing Method:Punching and Shearing Mould

- Material:High Carbon Chromium Tool Steel

- Application:Hardware, Car

- Warranty:1 Year

- Technics:Forming Die

- Process Combination:Progressive Die

Base Info

- Transport Package:Wooden Case, Cartons for Parts.

- First Trial:45 Days After Drawing Confirmed

- Tool Material:SKD11, Cr12MOV, 45#, Cr12

- Certificate:ISO9001:2015

- After-sales Service:Yes

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:Normal Speed

- Mold Cavity Technology:CNC Milling

- Driving Motor Type:Permanent Magnet

- Manufacturing Technology:Computer Technology

- Model NO.:HRD-20200827

- Specification:ISO9001: 2015

- Trademark:Higrade

- Origin:Qingdao, Shandong Province

- HS Code:8207300090

- Production Capacity:500sets,Year

Description

Basic Info.

Model NO. HRD-20200827 Manufacturing Technology Computer Technology Driving Motor Type Permanent Magnet Mold Cavity Technology CNC Milling Milling Speed Normal Speed Parts Detection Method Measurement of Three Axis NC After-sales Service Yes Certificate ISO9001:2015 Tool Material SKD11, Cr12MOV, 45#, Cr12 First Trial 45 Days After Drawing Confirmed Transport Package Wooden Case, Cartons for Parts. Specification ISO9001: 2015 Trademark Higrade Origin Qingdao, Shandong Province HS Code 8207300090 Production Capacity 500sets/YearProduct Description

Progressive Sheet Metal Stamping DiePlace of origin: Qingdao, China

Mould material: SKD11, Cr12MOV, and so on.

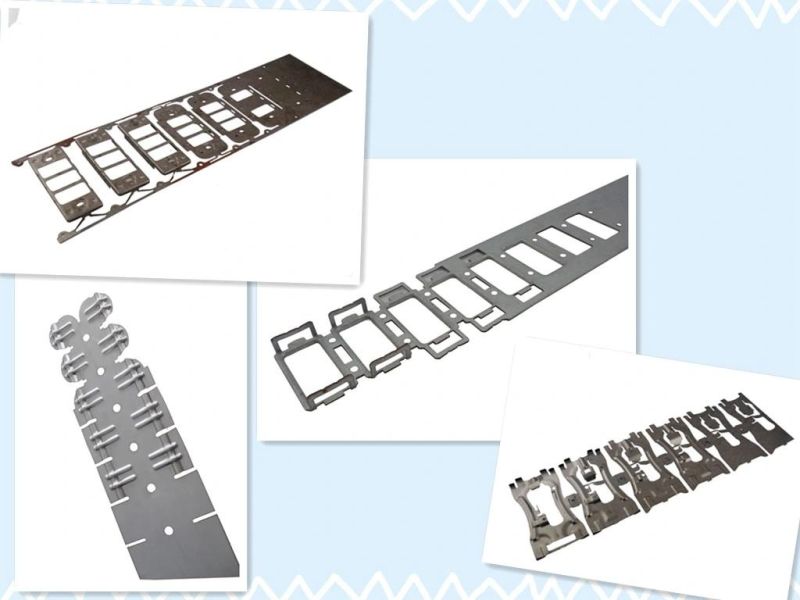

STAMPING PARTS:

1) We specialize in stamping parts, stamping die, sheet metal moulds, including the progressive mould. We had export some progressive moulds to Japan, Italy, Iran, Germany, USA, Russia, South America etc.

2)The stamping parts are related to home appliance, auto parts, electronic products, and so on.

3)ISO9001: 2015 certified by SGS.

PROGRESSIVE DIE:

We accept the following file types of inquiry: PRO/E Solidworks UG AutoCAD Adobe Acrobat Dxf. Pdf. X_t. STP. Igs. Prt.

We have confidence in cooperating with you!

| Item | Description |

| Staming die material | CR12MOV, SKD11, 45# etc. |

| Cavity | Single/Multiple |

| Drawing format | . igs, . step, . x_t, . pdf, . dwg, . dxf, |

| Metal parts material | SPCC, SUS304, SECC, AL, CU etc. |

| Mould life | 50000~500000 shots |

| First trial time | 20~35 days after mould structure drawing confirmed |