Plastic Injection Moulding Machine Details Core and Cavity in Plastic Molding

SUZHOU JUNDU M&E SCI-TECH CO., LTD.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Painting

Base Info

- Transport Package:Customized Packaging

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Trademark:Jundu

- Origin:China

- Production Capacity:100 Ton,Tons Per Day

Description

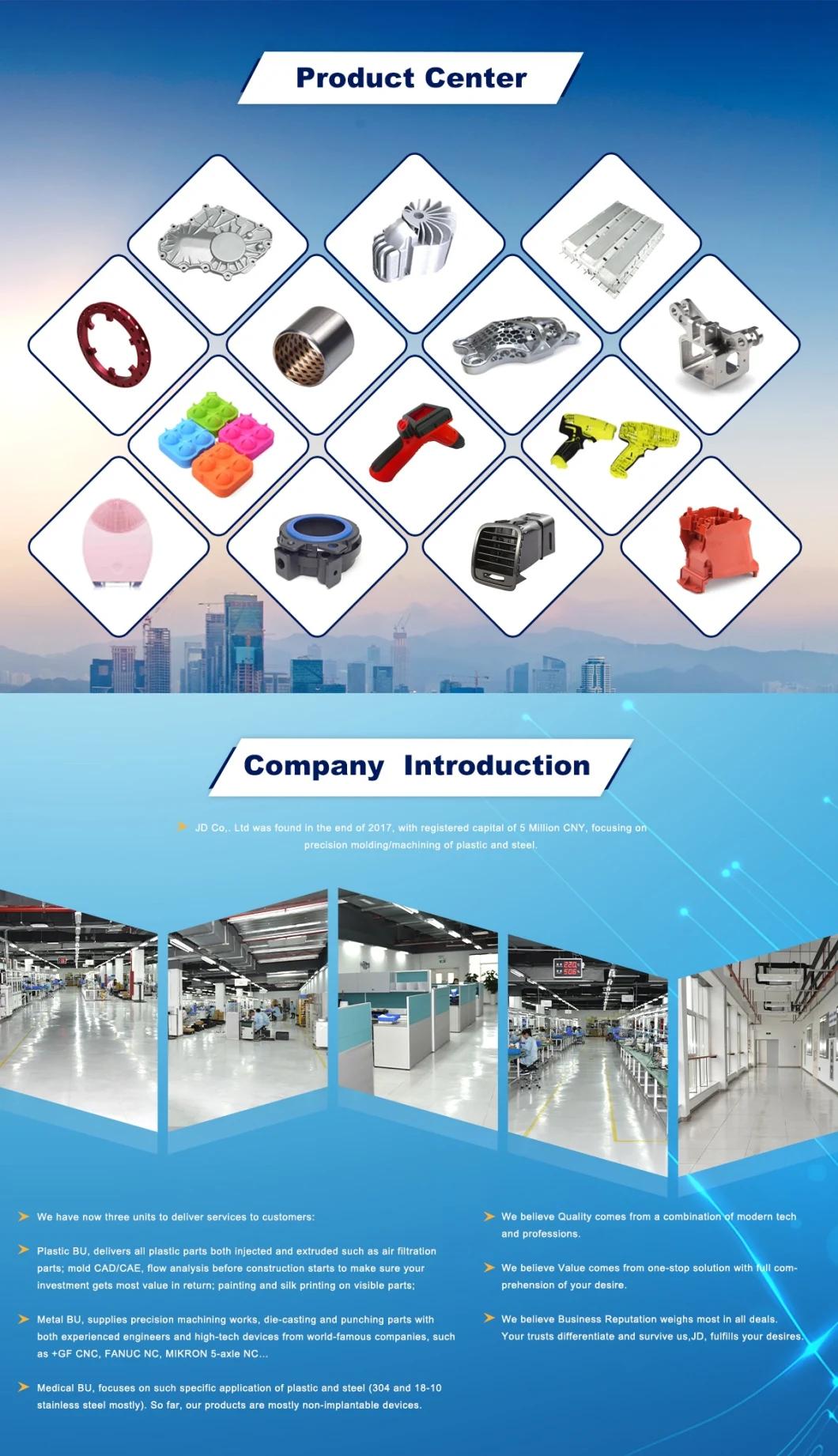

SUZHOU JUNDU M&E SCI-TECH CO., LTD.

With our state of the art production and modern CNC machinery we produce low and high quantities with highest standards.• Metal Fabrication and Welding, Robot Welding• Metal stampings, Robot stamping• Forming, Tube Bending• Mold Production, Casting

• Water-jet-, Laser- and Plasma-cutting

• Bending, Forging and Deep Drawing

• Machining (CNC Milling, Turning, Grinding, Drilling)

• Aluminum Extrusion

Material: Steel (Ordinary carbon steel, High strength low alloy structural steel…), Stainless steel, Aluminum, Non-ferrous material (Brass, Copper, Zinc…) and others

With our state of the art production and modern plastic-injection machineries partly imported from Germany, Taiwan, Switzerland and Japan we produce high quality plastic products with highest standard.

Injection mold, Extrusion mold, Rotation mold, Blow mold with optional Capacities:

•Clean room environment for food-grade products, even FDA approved.•Precision products at very tight tolerance, High polish and cosmetic features•Very large geometric sizes allowed (4.600 Ton machine), Surface finishing and packaging •Co-injection, hot-runner, in-mold decoration, Robotic injection molding for high quantity productionMaterial: PP, PE, ABS, PVC, PMMA, PS, Nylon, Rubber and additives such as UV inhibitor, Flame retardant...

Communicate clearly your requirements:

•Let us know the critical dimensions/specs so that we can prioritize accordingly•Let us know usage of the product/ parts if it is not business secret. This might affect manufacturing processes and quality measures.•If applicable, please let us know how you check for quality.•Carefully check for sample qualities before having us do mass production.•Use formal Engineering Change Management procedures Other Products and Services

Other Products and Services• Surface Treatment

Powder coating, Spray-painting, Plating, Printing, Galvanizing, Polishing, Anodizing …

• Assembly and functional test for:

Electro-mechanical products: Wearable Electronics, Medical Devices and more...

Electrical components For example, you may ask us to buy the components from a supplier appointed by you.

• Packaging, Warehouse service

• International Shipping and custom clearance.