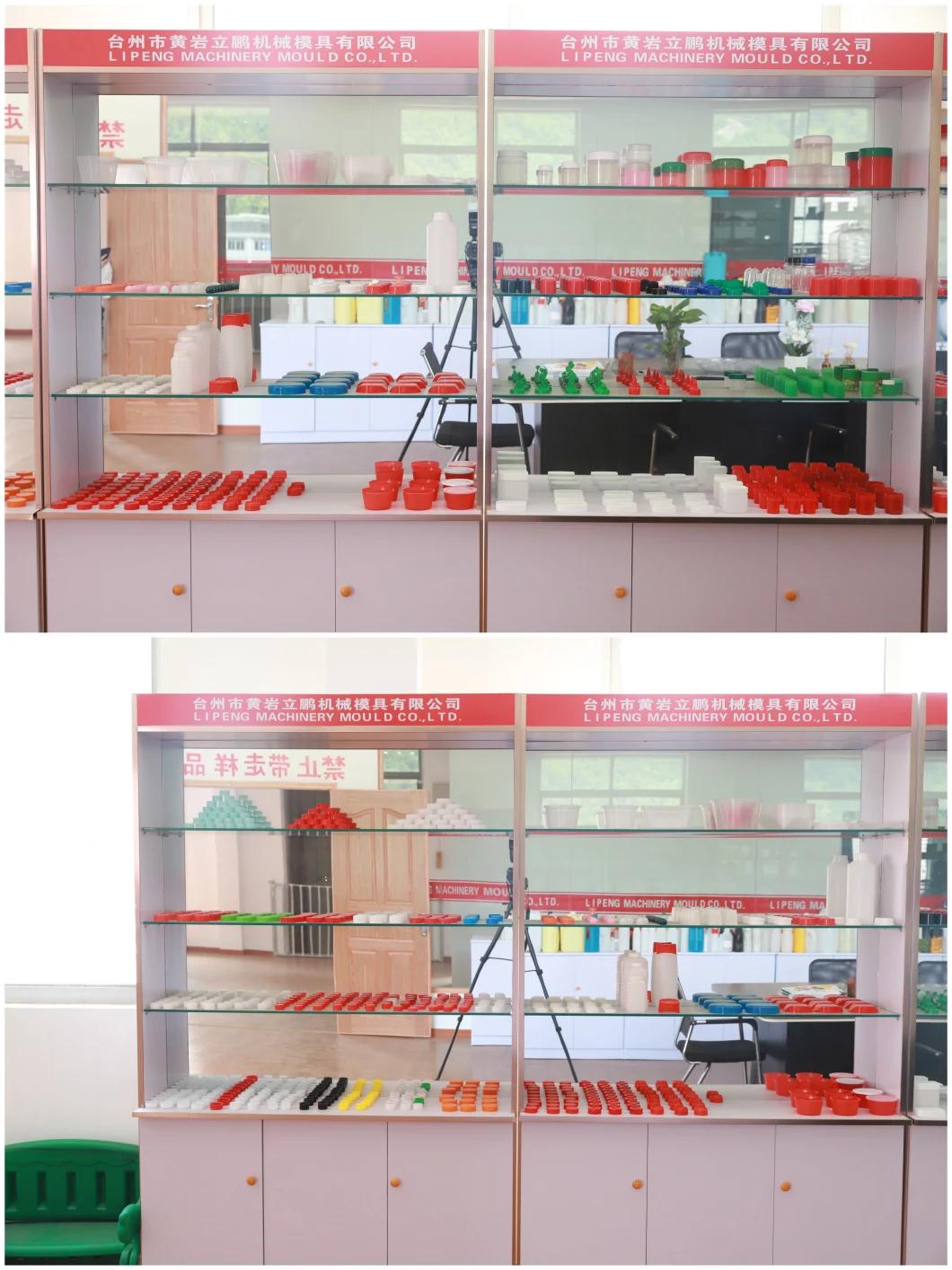

Plastic Flip Top Cap Mould Ready for Ship China Manufacturer

Taizhou Huangyan Lipeng Machinery Mould Factory- Process Combination Type:Compound Die

- Plastic Material:PP

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances, Commodity, Home Use, Packing

Base Info

- Trademark:LIPENG

- Transport Package:Wooden Case

- Customized:Customized

- Standard:DME

- Certification:CE, ISO

- Installation:Fixed

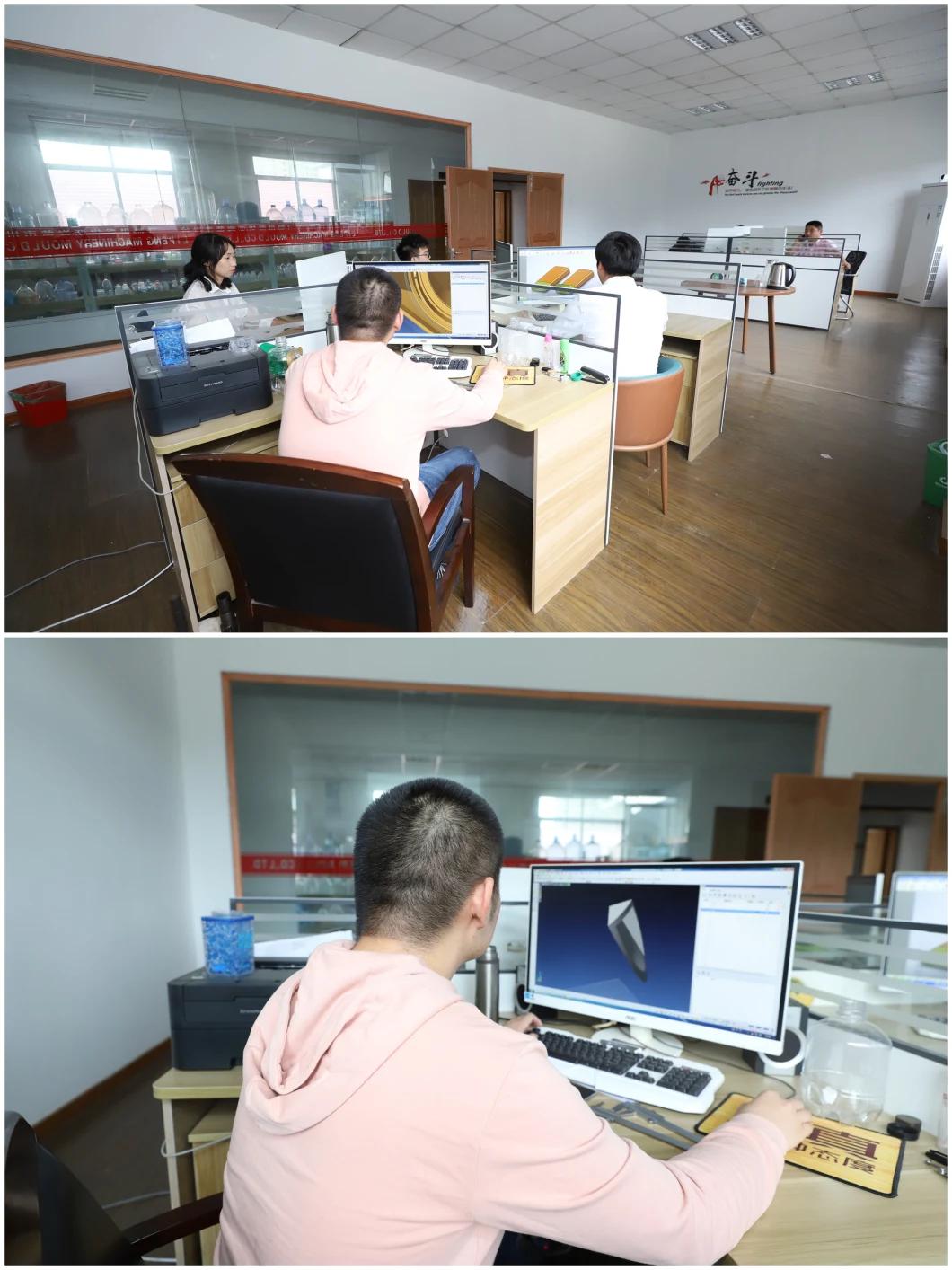

- Design Software:UG

- Runner:Cold Runner

- Origin:China

- HS Code:84790090

- Production Capacity:500sets,Year

Description

Basic Info.

Runner Cold Runner Design Software UG Installation Fixed Certification CE, ISO Standard DME Customized Customized Transport Package Wooden Case Trademark LIPENG Origin China HS Code 84790090 Production Capacity 500sets/YearProduct Description

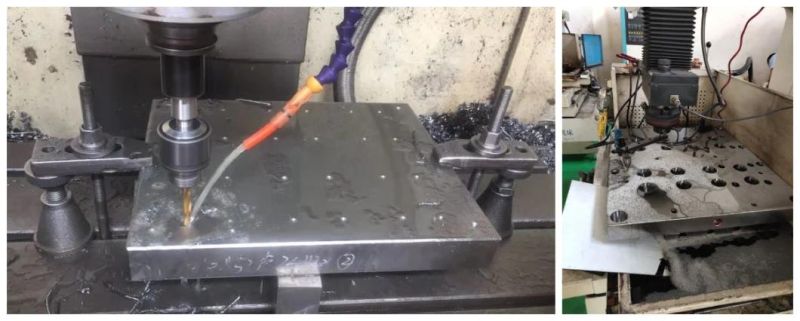

LIPENG MACHINERY MOULD CO.,LTD is located in "China mold town - Huangyan, Zhejiang, land, sea and air transportation is convenient.The factory has 20 years of mold development, experience in the design, mold design and manufacture of professional manufacturers. The use of advanced CAD / CAM / CAE software system is strong, production equipment, including Computer three-dimensional measuring instrument, small, medium and large machining centers, high-speed carved, CNC lathes, CNC wire cutting, EDM and all kinds of general-purpose equipment, greatly shortening the duration of mold manufacturing, mold.

Cap mould specification

| Name | cap mould |

| Mould Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#,45# etc |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc |

| Cavity No. | Single or multi |

| System Of Runner | Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

| Ejector Type | Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc |

| Term Of Mould Production | 20days- 30days |

| Guaranteed Number Of Cycles | 300,000-3000,000 closing |

| Mould Design Software | Ug,Proe,Solidworks AotoCAD,Moldflow,ect |

1. Specialized in manufacturing plastic injection mould and Bottle Cap Mould .

2. Good quality Bottle Cap Mould manufacturer

3. Competitive price

4. Punctual delivery time

5. High precision Bottle Cap Mould

6. Good after-sale service

Our Trade process:

1.R&D Customers provide the bottle cap design or samples for us

2.Negotiation Mutual discuss for the materials ,the price ,delivery time etc

3.Place the order Strictly do according to the order to meet our customer needs

4.Mould Design confirmation by our customer-Mold making strictly by the design

5.Sample Trial sample-our customer confirm -move forward to batch production

6.Delivery Delivery could according to our customers required by sea