BMC SMC Plastic Injection Molding Products

Yuyao Xianghao Mold Technology Company Limited- Product Material:Plastic

- Material:NAK80

Base Info

- Transport Package:Steel Box

- BMC Injection Product:BMC Injection Molding

- Customized:Customized

- Warranty:5 Years

- Certification:CE, RoHs

- Mould Life:>1000000 shots

- Heating System:Electric

- Demoulding:Automatic

- Cavity:Multi-cavity

- Model NO.:BMC SMC plastic injection products

- Specification:BMC injection product

- Trademark:BMC injection product

- Origin:Chian

- HS Code:8480710090

- Production Capacity:100PCS Per Month

Description

Basic Info.

Model NO. BMC SMC plastic injection products Cavity Multi-cavity Demoulding Automatic Heating System Electric Mould Life >1000000 shots Certification CE, RoHs Warranty 5 Years Customized Customized BMC Injection Product BMC Injection Molding Transport Package Steel Box Specification BMC injection product Trademark BMC injection product Origin Chian HS Code 8480710090 Production Capacity 100PCS Per MonthProduct Description

BMC injectionBMC injection product

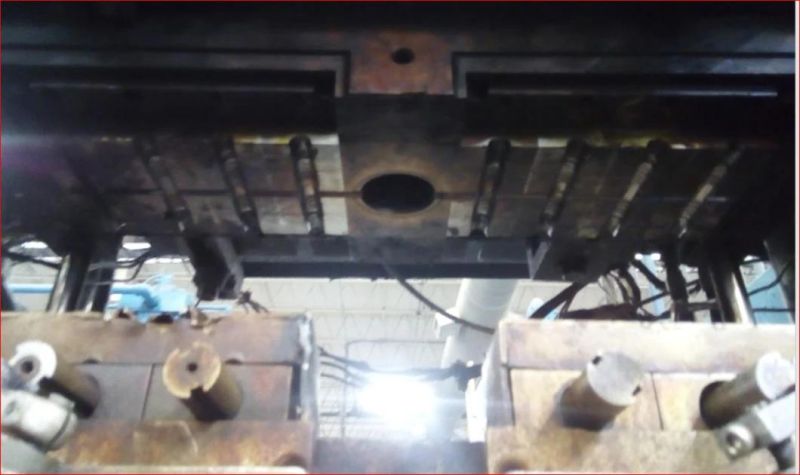

BMC. injection mould

BMC. injection parts

bmc parts

BMC injectionl

bmc injection

bmc injection molding

bmc injection molding process

bmc injection molding machine

cpt bmc injection

injection molding bmc mold temp

bmac injection process

BMC (Bulk Molding Compound) is a thermoset resin blend of various inert fillers, fibers reinforcement, catalysts, stabilizers and pigments, used for injection molding most of the time.

BMC material is highly filled and reinforced with short fibers : glass reinforcement represents between 10% and 30%, with glass length between 6mm and 12mm.

Depending on the end-use application, bulk molding compounds are formulated to achieve close dimensional control, flame and track resistance, electrical insulation, corrosion and stain resistance, superior mechanical properties, low shrink and color stability.

Its excellent flow characteristics, dielectric properties and flame resistance, make the BMC material adequate to a wide variety of applications, requiring precision in detail and dimensions as well as high performance.

The BMC material is available in a broad type of colors, and can tolerate powder-coat and water-based paint.

| Product Name | BMC SMC plastic injection products |

| Certificate | ISO9001 |

| Application | Power Electric, Automotive Parts, Building Decoration, etc. |

| Production Equipment | CNC, EDM Machine, Wire Cutting Machine, Carving Machine, Lathe DrillingMachine, Grinding Machine, Milling Machine, Injection Molding Machine, Four-column Hydraulic Press, Integral Frame Type Hydraulic Press |

| QC Machine | 3D Measurement, Profile Projector, Hardness Tester and other regular size inspection |

| Mold Cavity | Single or Multi Cavities Available |

| Runner System | Hot runner,Cold runner, etc |

| Mould Base | LKM, HASCO, DME etc |

| Mould Material | P20, 738, 738H, 718, 718H, NAK80, S136, S136H, 2378H, 2311, 2083, 2316, H13, SKD61, 2344, 8407 or as customer require. |

| Composite Material | SMC, BMC |

| Mold Lead Time | 28-30days for T1 samples , exact time depends on Mould Complexity |

| Mould Life | 300,000 - 1,000,000 shots |