Customized Home Appliance Injection Plastic Mould for Washing Machine Rear Tub/Front ...

Qingdao Chuangyu Precision Machinery Co., Ltd.- Surface Finish Process:Anodizing

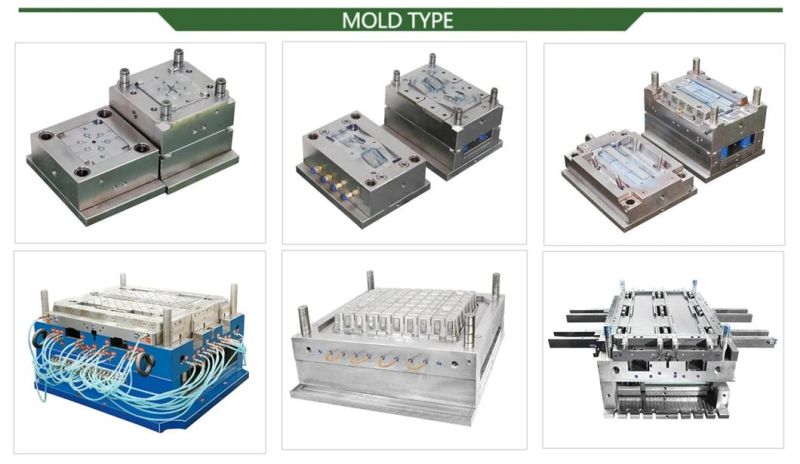

- Mould Cavity:Multi Cavity

Base Info

- Transport Package:with PE Plastic Packed Then Into The Wooden Box

- Material:ABS, PP, PC, POM, HDPE, PA6, TPU, etc

- Logo Method:Laser Engraving, CNC Engraving, Scree

- Surface Treatment:Anodizing, Powder Coating, Painting etc

- OEM/ODM:Yes

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, CE, ISO, FDA

- Installation:Fixed

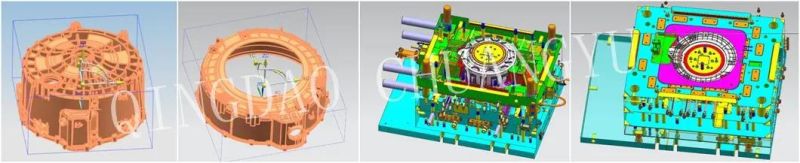

- Design Software:AutoCAD

- Runner:Hot Runner

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:HDPE

- Model NO.:CMP01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8480419000

- Production Capacity:20pieces,Month

- Package size per unit product:5.00cm * 10.00cm * 5.00cm

- Gross weight per unit product:0.200kg

Description

Interior door mold, Engine cap mold, Car light mold, External trim mold, Car bumper mold, Car dashboard mold, Car mirror mold etc

Detergent drawer mold, Pulsator mould, Control panel mould, Washing machine cover mould, Rear Tube mould, etc

Vent lock mould, Window keeper mould, Window trim mould, etc

Trim mold, Shelf mold, Icebox mold, etc

Plastic Injection Molds for different market, such as household mold, automotive mold, medical mold, window and door mold, high-speed rail mold, aircraft mold, etc

Plastic injection mold products in different materials, such as abs mold, pp mold, pc mold, hdpe mold, pom mold, pe mold, nylon mold, tpu mold, tpe mold, etc

Plastic injection mold products in different materials, such as abs mold, pp mold, pc mold, hdpe mold, pom mold, pe mold, nylon mold, tpu mold, tpe mold, etc Professional design team could help you to design and modify the drawing, QC team to inspect all the parts before shipment to ensure the good quality.

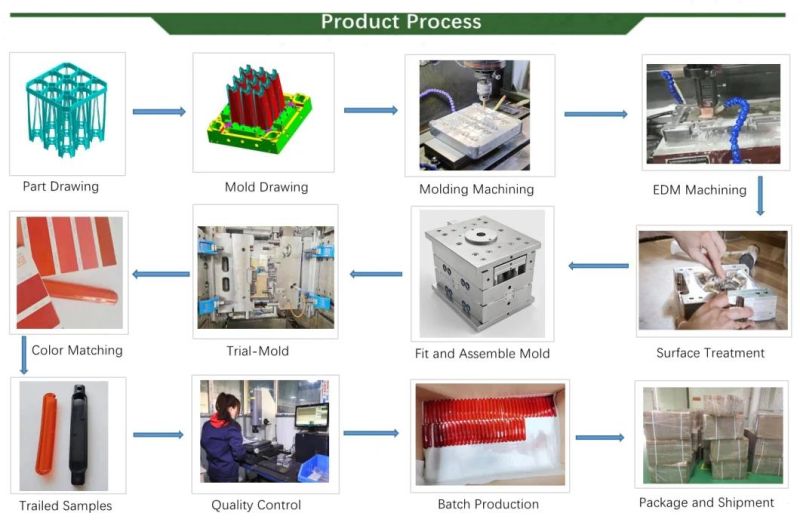

Professional design team could help you to design and modify the drawing, QC team to inspect all the parts before shipment to ensure the good quality.

FAQ:

FAQ:1. Q: What is the processing for the quote?

A: We can quote from your 3d formats like IGS, STP, PARASOLID, etc and 2D drawings as well; quote the price to clients after got the 2d or 3d drawings within 2 hours;

2. Q: How is the next?

A: We will send the cost to you and get your confirmations for the quote;

3. Q: What is the software will you use for the proceeding?

A: We make the 3D program with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM, etc ;

4. Q: what is the type of machine for manufacturing?

A: Manufactured from CNC Machining, Laser cutting, stamping, injection as well as the parts files different ;

5. Q: Do you do the surface treatments, please?

A: Yes, sure. we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting ;

6. Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;