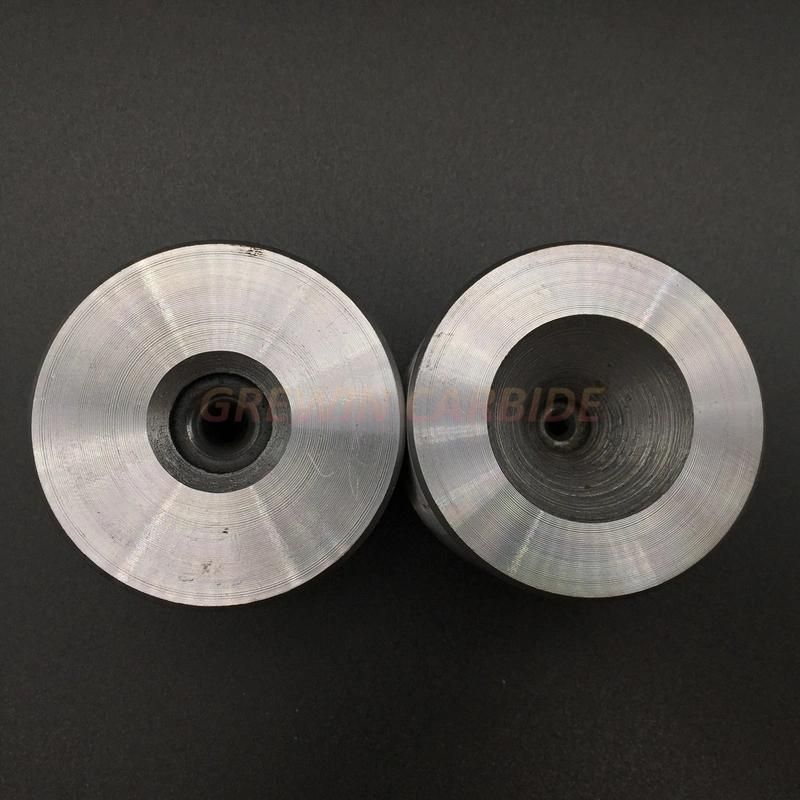

Gw Carbide - K10 Tungsten Carbide Moulds for Puching and Forming Tool Clamp

Zhuzhou Grewin Tungsten Carbide Tools Co., Ltd.- One-time Molding:Not One-time Molding

- Forging Work Steps:Automotive Half Shaft Forming Forging

- Craftwork:The Long Axis Type

- Material:Tungsten Carbide

- Application:Hardware, Car

- Certification:ISO, SGS

Base Info

- Samples:Free

- OEM:Accepted

- Place of Origin:Zhuzhou--Carbide City

- Raw Material:100%

- Certificates:ISO,SGS etc

- Sizes:All Is Avaiable

- Working Materials:Steel, Cast Iron, Aluminum, Stainless Steel etc

- Characteristics:High Hardness, High Precision etc

- Condition:New

- Customized:Customized

- Metal Color:Black Metal

- Warranty:6 Months

- Model NO.:all sizes

- Delivery Time:15-25 Days

- Transport Package:Standard Export Carton

- Specification:33 x 23 x 19cm

- Trademark:GW

- Origin:Zhuzhou Hunan

- HS Code:8207209000

- Production Capacity:100 Tons Annually

Description

(g/cm3)

(N/mm2)

(HRA)

3. Production process

Mixture(WC+CO+alcohol)→wet grinding→ drying→grinding again→suppression(Oil press,Automatic hydraulic press)→QC for blank→rubber extrusion→Wc+Co→sintering(HIP )→tungsten carbide blank→Fine grinding→QC→packing.

4.Products Show

More information, please kindly contact us.

Best regrads

GREWIN CARBIDE