Custom Making P20 Injection Tooling Mold for Plastic Molding

Dongguan Howe Precision Mold Co., Ltd.- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Polishing

Base Info

- Cavity:Single or Multi Cavity

- Lead Time:20~35day

- Finish:Pitting The Word, Mirror Finish, Matte Surface

- Process:Injection Molding

- Mould Material:2344, 8407, HD, 8418, etc

- Material:ABS+PP, ABS, PP, PMMA, etc

- Mould Life:300, 000-500, 000 Shots

- Product Name:Plastic Inject Moulds

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Pro-E

- Runner:Cold Runner

- Model NO.:HW-905

- Place of Origin:Guangdong, China

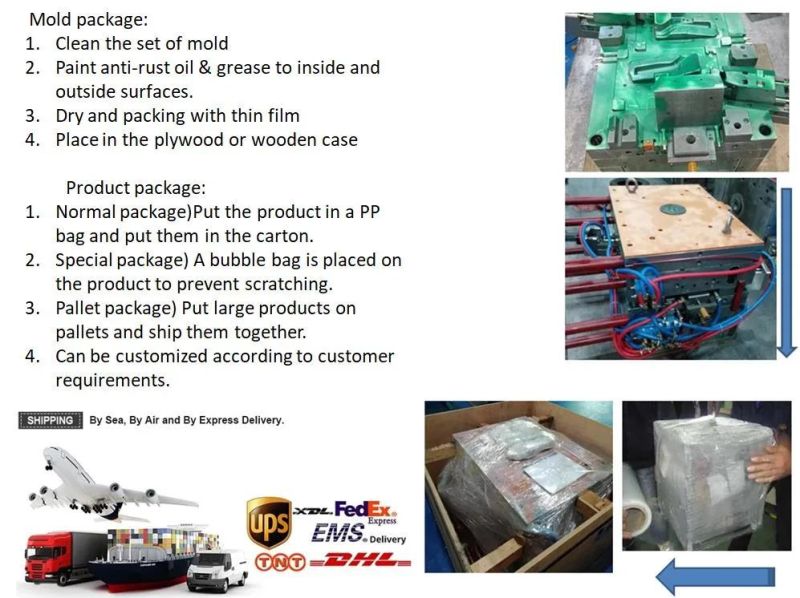

- Transport Package:Wood Box and Wood Pallet

- Specification:According to your drawing

- Trademark:Custom

- Origin:Guangdong, China

- HS Code:8522901000

- Production Capacity:40sets,Month

Description

Advantage

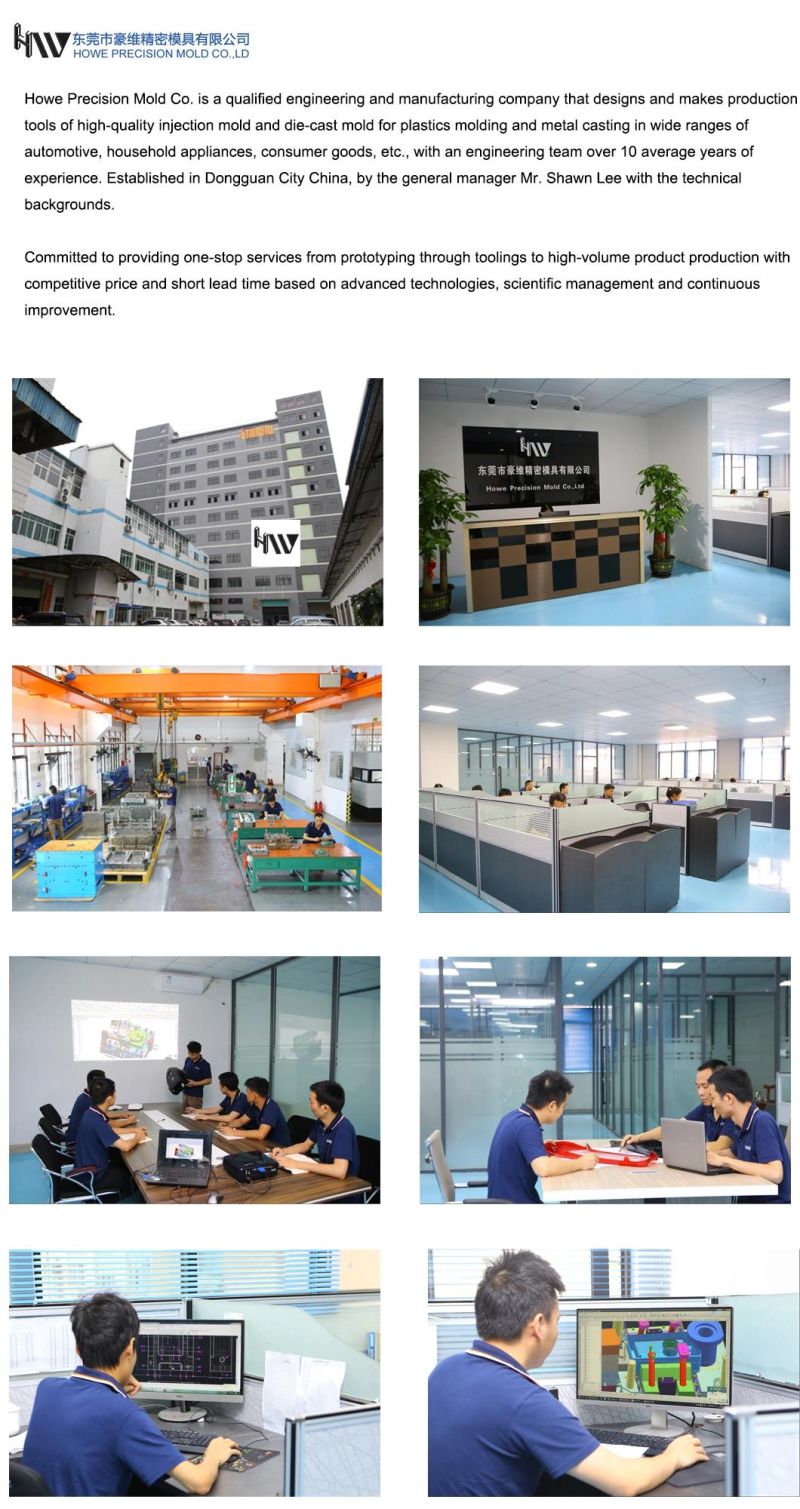

1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 11 years.

2. Long term cooperation with some Top Brand Auto Industry, such as Volvo.

3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification.

4. Equipment includes CNC, EDM, grinding machine, injeciton machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products.

5. We offer unique solutions to your products at a competitive price and best service.

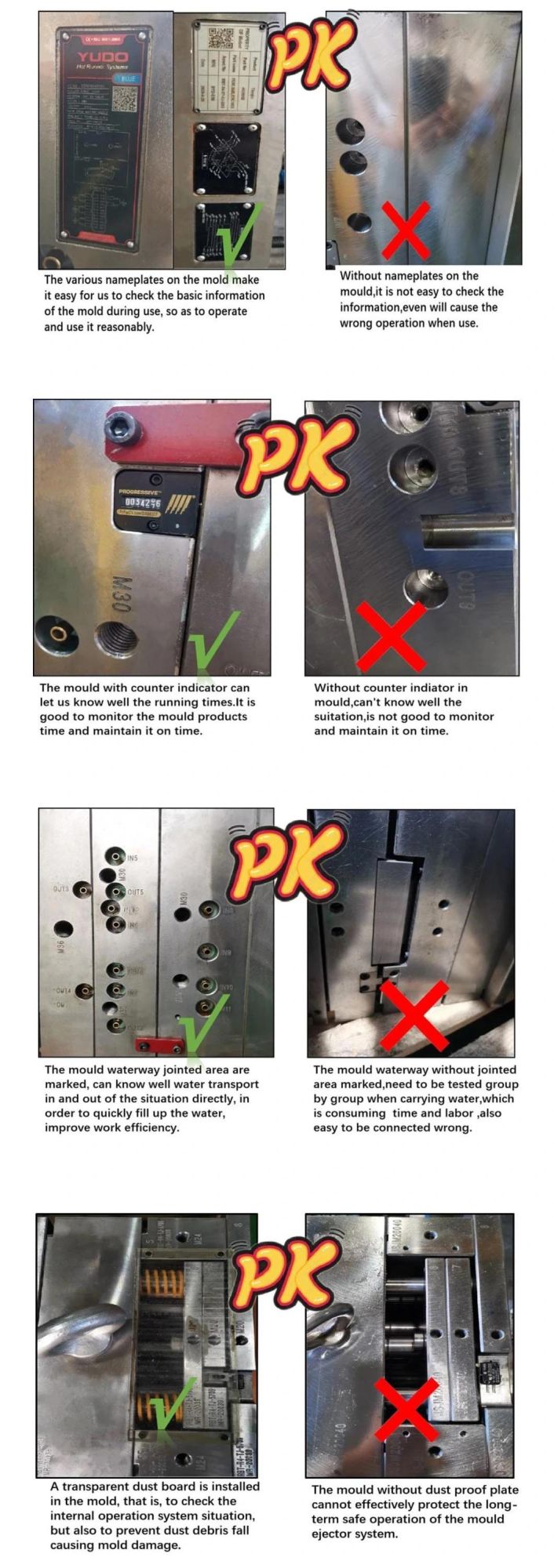

6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold.

7. Quick mold making and on-time delivery.

8. We accept small order quantity, look forward to receiving your inquiry.

9. Excellent R&D teams, Professional technicians and rich experienced workers.

10. Providing good After-sale service, if the products have any quality problems, we will take charge of it.

Quality Control

Work Shop

Mould Trade Process

Quote: According to sample, drawing and specific requirement.

↓

Discussion: Mould material, cavity number, price, runner, payment, etc.

↓

S/C Signature: Approval for all the items

↓

Advance Pay: 40% by T/T

↓

Product Design Checking: We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report

↓

Mould Tooling: We start to make mould after mould design confirmed

↓

Mould Processing: Send report to customer once each week

↓

Mould Testing: Send trial samples and try-out report to customer for confirmation.

↓

Pay :30% by T/T on trial samples

↓

Mould Modification: According to customer's feedback

↓

Balance settlement: 30% by T/T after the customer approved the trial sample and mould quality.

↓

Delivery: Delivery by sea or air. The forwarder can be designated by your side.

Plastic Sample Room

Business Cooperation

Package and Shipment