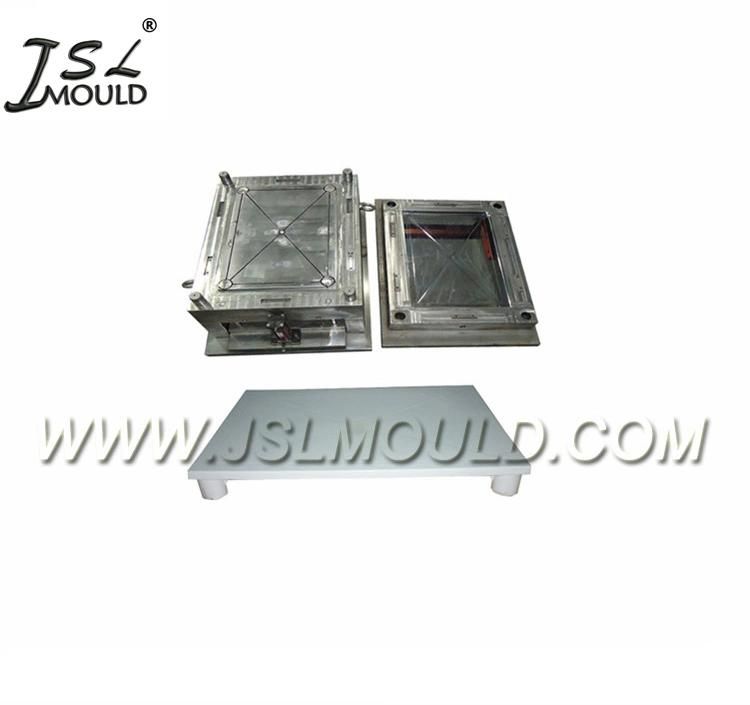

Premium Customized Injection Plastic Table Mold

Taizhou City Huangyan Beiwei Mould Industry Co., Ltd.- Plastic Material:PP

- Mould Cavity:Single Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Process Combination Type:Single-Process Mode

- Application:Home Use

Base Info

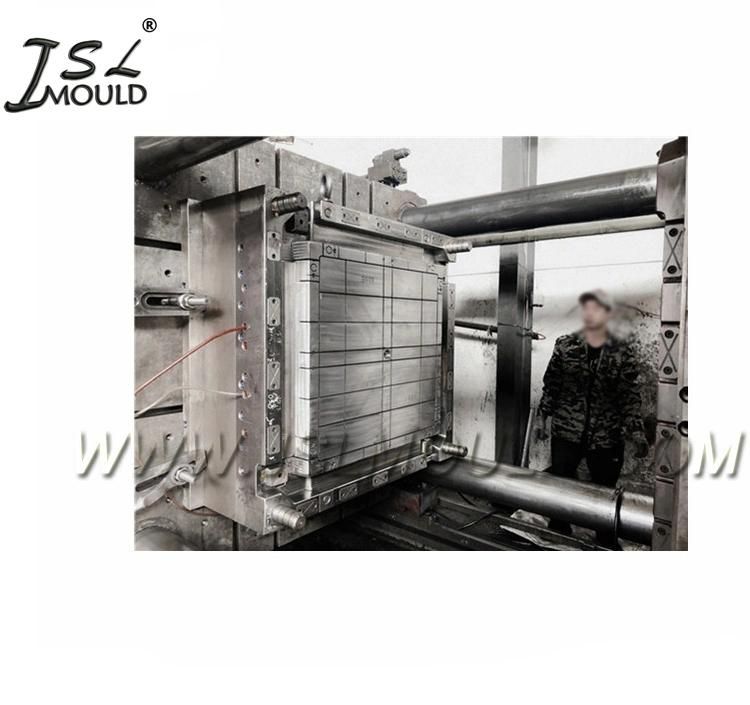

- Mould Operating:Automatically by CNC

- Mould Cooling System:by Experienced Designer

- Mould Quality Control:Professional QC in House Machine

- Heat Treatment:Nitriding

- Machine Equipment:CNC,EDM,Wire Cutting Machine,Drilling Machine

- Mould Base:S50c,C45

- Customized:Customized

- Standard:DME

- Certification:ISO

- Installation:Fixed

- Design Software:Ug,Proe,CAD,Catia,Solidworks

- Runner:Hot Runner, Cold Runner

- Model NO.:JSL-T1773-3

- Mould Design:7days

- Mould Report:7-10days Per Time

- T1 Sample:50days

- Transport Package:Wooden Case

- Specification:DME

- Trademark:JSLMOULD

- Origin:China

- HS Code:8480719090

- Production Capacity:500sets,Year

Description