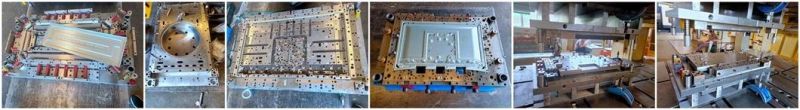

OEM Sheet Metal Single Punching Mold/Tooling or Progressive Stamping Die Used for Auto ...

Qingdao Chuangyu Precision Machinery Co., Ltd.- Processing Method:Punching and Shearing Mould

- Material:High-Speed Steel

Base Info

- Transport Package:with PE Plastic Packed Then Into The Wooden Box

- OEM/ODM:Yes

- Polish:High Polish

- Standard:Hasco

- Certification:CE, ISO

- Installation:Fixed

- Design Software:Autocad

- Process Combination Type:Progressive Stamping Mold

- Surface Finish Process:Zinc-Plated, Nickel-Plated, Tin-Plated etc

- Item:Metal Stamping Mold

- Parts Detection Method:Measurement of Three Axis NC

- Milling Speed:High Speed

- Mold Cavity Technology:EDM Milling

- Driving Motor Type:Permanent Magnet

- Manufacturing Technology:Automation Technology

- Process Combination:Progressive Die

- Technics:Forming Die

- Model NO.:CMP01

- Specification:up to design

- Trademark:Chuangyu

- Origin:China

- HS Code:8207300090

- Production Capacity:50pieces,Month Metal Stamping Die

- Package size per unit product:3.00cm * 1.00cm * 1.00cm

- Gross weight per unit product:0.150kg

Description

Chuangyu specializes in manufacturing and supplying of various moulds and dies, such as metal stamping dies, plastic injection moulds, motor stator&rotor molds and stamping parts and injection parts since 2009.

"Good quality with cost-effective" is the base of our business. Our people keep creating value for customers as our mission.

ISO 9001: 2015 certificated.

We also make plastic injection molding, silicone rubber mold and CNC machining parts

Factory:

To work with us, we do not just stop at taking your order and offering you molds and molding parts, we work together at every step all the way, in the design and function testing until the end of the project, we will review all of the possible potential issues and bring all of the suggestion to you. After the first sample parts coming out, our expert team will send you samples and review the parts, and we will re-sample for you from time to time until you have the perfect goods in surface, function, assembly, etc, until completely achieve your goal, your will find out we are the most responsible mold company that to support your business.

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

FAQ:

FAQ:1. Q: what is the processing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well; quote the price to clients after got the 2d or 3d drawings within 2 hours;

2. Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote;

3. Q: what is the software will you use for the proceeding ?

A: We make the 3D programm with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM etc ;

4. Q: what is the type of machines for manufacturing ?

A: Manufactured from CNC Machining, Laser cutting , stamping ,injection as well as the parts files different ;

5. Q: Do you do the surface treatments please ?

A: Yes, sure. we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting ;

6. Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;