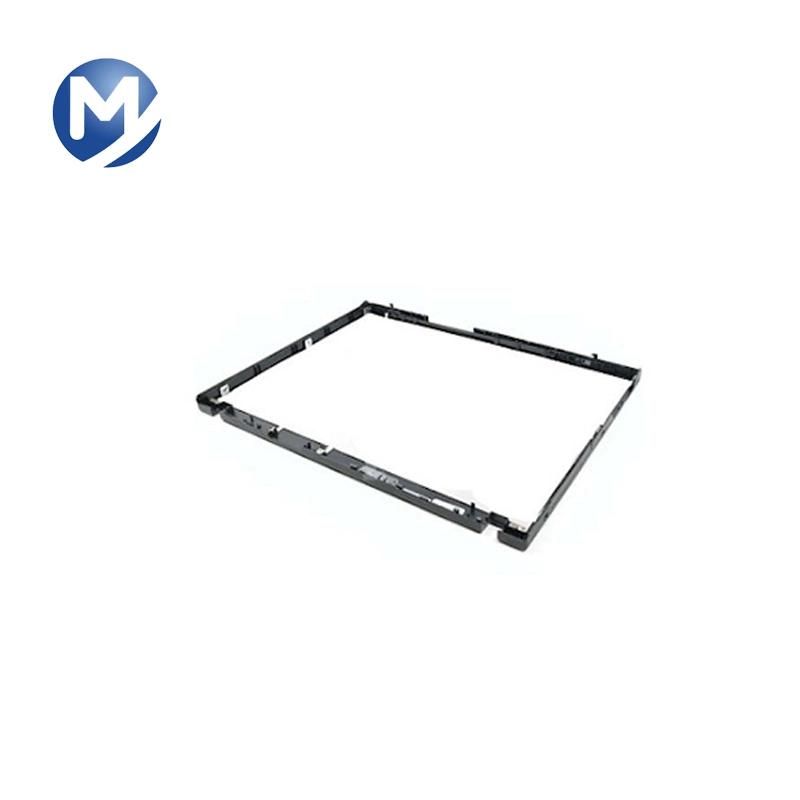

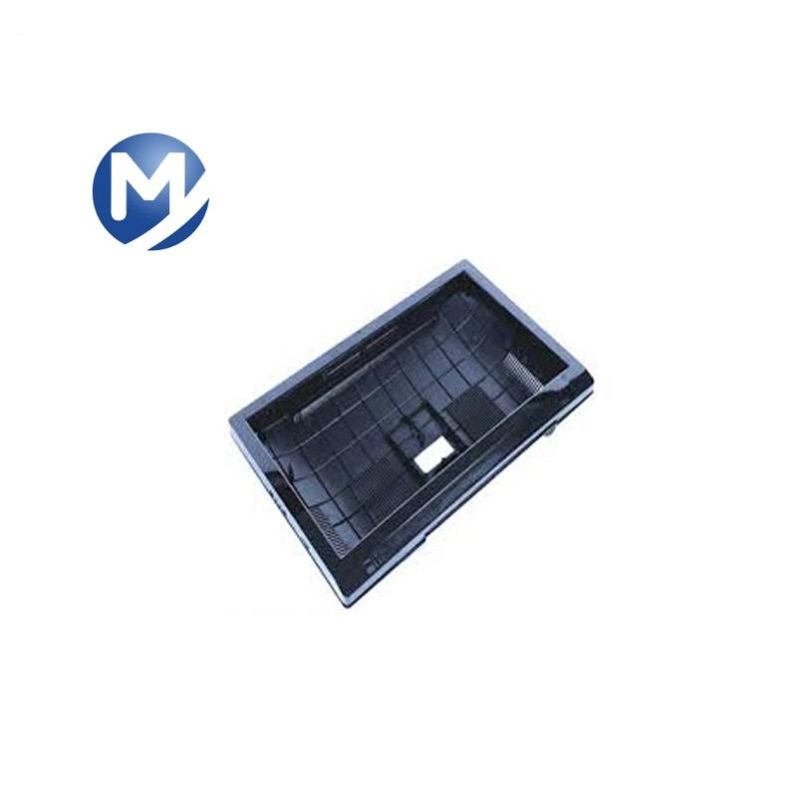

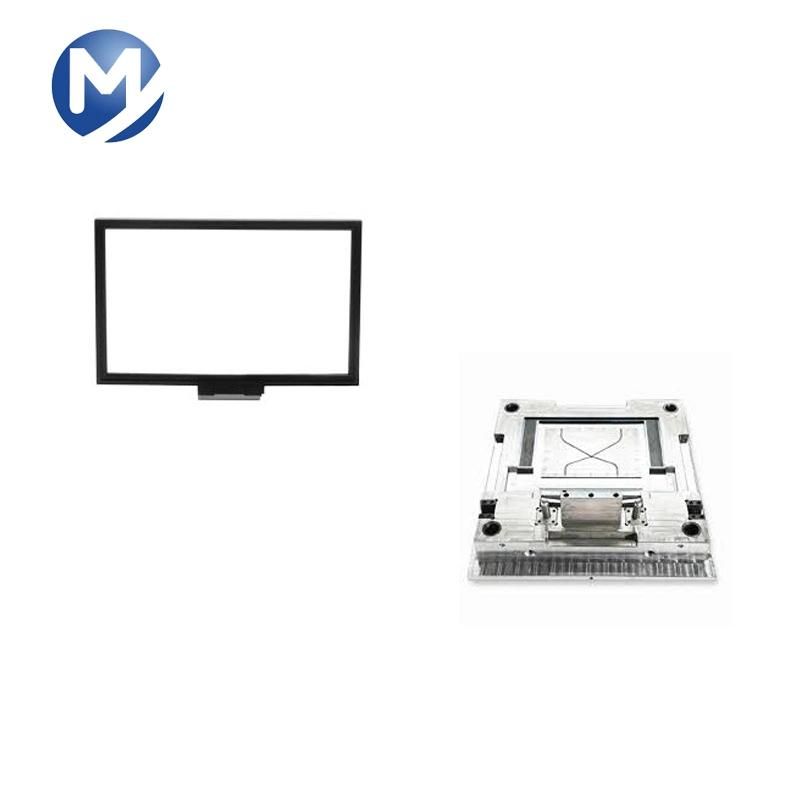

Plastic Injection Tool for LCD LED Computer TV Screen Plastic Frame

Shanghai MY Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:ABS

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Mirror Polishing

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Heat Treatment of Steel:HRC48-52

- Shape:Based on Drawings

- Production Material:as Per Client′s Requirement

- Cavity:as Per Client′s Requirement

- Cycle Time:15-60s

- Mold Steel:P20,718,2738h,Nak80,H13,8407,1.2344

- Gate Type:Yudo Runner, Hot Runner, Cold Runner, Sub Gate,Edg

- Customized:Customized

- Standard:Local,Hasco,Dme,Misumi

- Certification:TS16949, ISO, FDA

- Installation:Fixed

- Design Software:Ug,CAD,Moldflow,Proe,Catia,Solidwork

- Runner:Hot Runner

- Model NO.:w191

- Our Service:Dfm Report,Mould Flow,Mould Design,Mpr,QC Report,

- Transport Package:Carton

- Specification:Customized

- Trademark:MYMOULD

- Origin:Shanghai, China

- HS Code:8480719090

- Production Capacity:50 Sets,Month

Description

Mould material

Plastic mould material: P20 steel, 718, 2738,H13, NAK80,2344,2343,S136,etc....

Fast mould design

can be within 1-3 working days after getting customer's drawings

Lead time

Plastic moulds :3- 6 weeks after getting the mould desig n confirmation.

Mould testing

All of the moulds can be well tested before the shipments. Videos for testing the moulds are available.

Minimum order:

small orders can be accepted.

Production capacity

50 sets/month

Port

shanghai

Runner

Hot/cold

Payment terms

L/C T/T Western Union Money Gram.

Mould making service

OEM/ODM service available.

After sales service

Available by our staff with more than 10 years of working experience in this field.

Good packages

In strong wooden pallets to avoid any damages during the long transportation

Why Customers Choose Us?

Why Customers Choose Us?| We have been engaged in this field for 15 years, we've served customers from the United States, the United Kingdom, Spain, Australia, Singapore, Russia and other countries. |

| Professional Certification |

| Quality control and technology improvement |

| •ISOIS09001:2000 |

| •SGS certificate |

| •The complete quality control system. |

| Precision durable mold. |

| •3 CNC: Precision 0.005mm |

| •1 Three dimension:1Precision 0.001mm |

| •1 wire drive slowly: Precision 0.002mm |

| •2 Mirror discharge: Precision 0.005mm |

| 100% Guaranteed Quality |

| •100% tested(Not Just Batch Tested) |

| •SOP standard production. |

| •IQC(tested all in matical )-IPQC(tested first parts and prodcut)-FQC(tested finished parts)-OQC(Shipments) |

| •10 professional quality control inspectors |

| Competitive price and service |

| •Delivery time: 2-3 Weeks after order |

| •Provide new design for customers' requirements |

| •Provide DFM Report,Moldflow,Mould Design,MPR,QC Report, Injection parameter sheet,Testing video. |

| •Free provided sample. |

| •10-20% cheaper than other competitors |

| •Return the entire mould cost if you order 500,000pcs product. |

| •Life-long guarantee period, which is much longer among this field. |