Plastic Electrical Box Injection Mould

Zhejiang Taizhou Huangyan Jingzheng Mould Co., Ltd.- Process Combination Type:Compound Die

- Plastic Material:PVC

- Mould Cavity:Multi Cavity

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Household Appliances

Base Info

- Specification:ISO9001-2000

- Transport Package:Wooden Case

- Thickness:2mm

- Customized:Customized

- Standard:HASCO

- Installation:Mobile

- Design Software:AutoCAD

- Runner:Cold Runner

- Trademark:JZ

- Origin:China

- HS Code:8480719090

- Production Capacity:100 Sets,Month

Description

Basic Info.

Runner Cold Runner Design Software AutoCAD Installation Mobile Standard HASCO Customized Customized Thickness 2mm Transport Package Wooden Case Specification ISO9001-2000 Trademark JZ Origin China HS Code 8480719090 Production Capacity 100 Sets/MonthProduct Description

Plastic Electrical Box Mold/MouldHigh quality with reasonable price, by using Chinese, Korean, Japan, Germany Standard to make moulds

| Name | Plastic Electrical Box Mold/Mould |

| Plastic material | PVC |

| Steel of Cavity & Core | DIN 1.2316 |

| Steel of Mouldbase | S50C. LkM standard^ etc |

| Nos of Cavity | Customized |

| Hardness of Cavity & Core | 48-52HRC |

| Hardness of Wear Parts | 55-60HRC |

| Core pulling system | Motor /oil cylinder/ stripping plate, angel pin^ etc |

| Mould Accessories | DME/HASCO Standard ^ |

| Cooling system | In core baffle cooling and in cavity plate chain drilling type cooling |

| Surface finish | Diamond polish, |

| Molding life | 1.200, 000shots |

| Runner | Cold |

| Delivery time | 60 work days |

| Packing | wooden case |

| Payment | T/T L/C |

Mould Making:

1.Samples/Drawing &Requirement from you

2.Mould design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and Mould base tooling.

4.Assembling.

5.Inspection of mould:following and controlling the tooling processing.

6.Mould testing:We will inform you the date.Than will send the sample's inspection, report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

Our advantages:

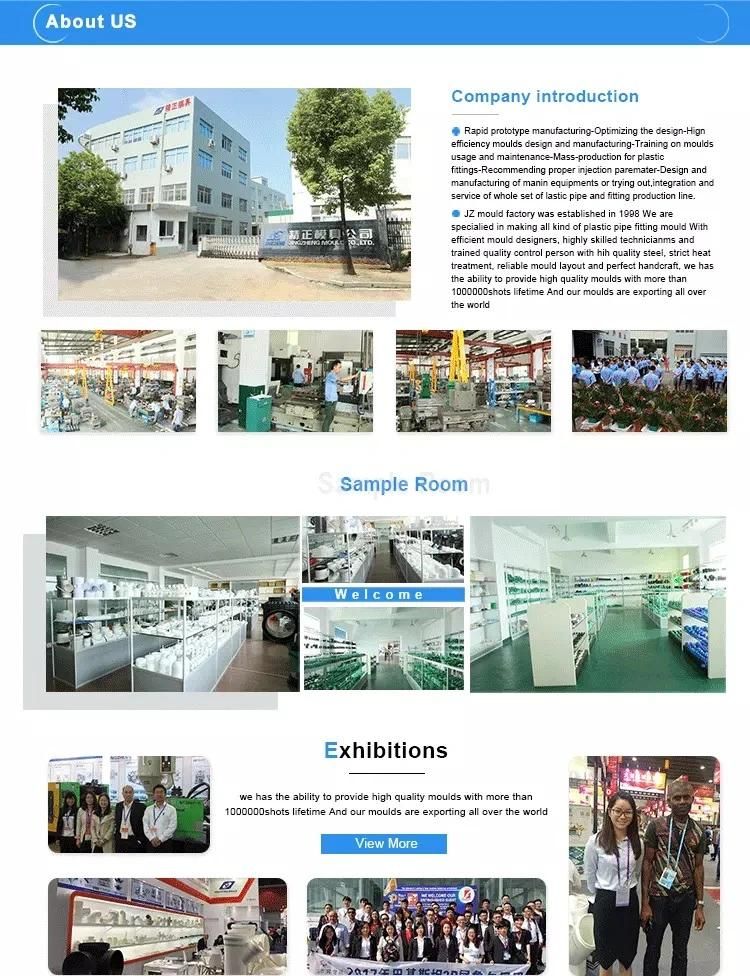

1.Good experience in mould making since the year of 1998.

2.Patent in collapsible fitting moulds.

3.Machinery core pulling system save cost and increase production efficiency.

4.Perfect core pulling distance within 180mm.

5.Excellent R&D team.(We can offer you 3D mould design with all details within one day.)

6.Efficiency production department.(We can finish Push-Fit fitting mould of size 110mm in stwo cavity with in 45days.)

7.Competitive price in save level of mould manufactuers.

Pls freely contact me for new inquire and further questions!